Stable Water Supply Under Electric Drive: Key Technological Highlights of the Vertical Fire Pump System

The electric constant pressure fire pump system features rapid high-pressure startup, intelligent pressure control, energy-saving operation, and fault detection. Ideal for high-rise buildings, hospitals, subways, and data centers, it ensures smart firefighting and efficient water supply.

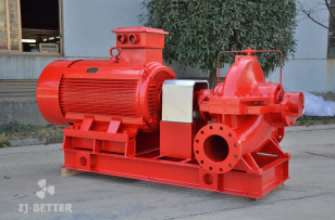

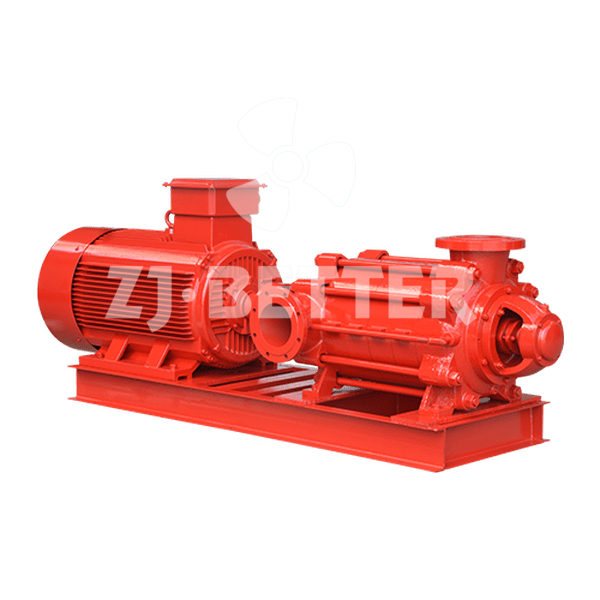

As a core component of modern building fire protection systems, the stability, high responsiveness, and automation level of electric constant-pressure fire pump systems have become key criteria for evaluating system performance. This system plays a crucial role in the initial response phase of a fire, not only achieving high-pressure startup in an extremely short time and rapidly raising water pressure to the predetermined value, but also automatically adjusting pump speed based on system pressure fluctuations to ensure continuous constant-pressure water supply. This ensures the stable operation of the fire suppression system while reducing resource waste and energy consumption. An electric constant-pressure fire pump system typically consists of an electric motor, water pump, control cabinet, pressure sensor, pressure stabilizer, and automatic start-stop module. These components are interconnected through a precise electrical control system, enabling the system to adapt effectively to varying fire conditions. Its intelligent control module continuously monitors pipeline pressure. Once pressure drops below the set startup threshold, the system automatically triggers the startup sequence, causing the motor to run at high speed and drive the pump to rapidly deliver water to the sprinkler system or fire hydrants. Additionally, the system automatically shuts down after fire suppression is complete based on feedback pressure, preventing overpressure and idle running. Compared to traditional fixed-speed startup equipment, the constant-pressure electric fire pump system uses variable frequency control technology to achieve stepless speed regulation, adapting to pressure demand changes in various fire scenarios. It demonstrates outstanding system stability and pressure control capabilities in complex spaces such as large shopping malls, hospitals, office buildings, rail transit systems, underground garages, and warehousing logistics centers. Its advanced PID control logic precisely regulates the pump’s output pressure, achieving a pressure error range of ±0.01 MPa, significantly enhancing fire extinguishing efficiency and system reliability. Additionally, the system features self-diagnostic functionality, capable of detecting anomalies such as abnormal power voltage, incorrect phase sequence, phase loss, control board failures, or sensor malfunctions, and promptly switching to backup equipment to ensure continuous operation of the fire protection system. To meet the high fire protection pressure requirements of high-rise buildings, this electric constant-pressure fire pump system adopts a multi-stage centrifugal pump structure, offering comprehensive performance with high head and large flow rates. The maximum head can exceed 180 meters, and the rated flow rate covers the range of 20–150 L/s, meeting the high-pressure water supply needs of various types of buildings. The pump body is made of high-strength ductile iron or stainless steel, offering excellent corrosion resistance and mechanical strength, effectively extending the equipment’s service life and operational stability. The pump impeller adopts a dynamic balancing design to ensure low vibration and low noise during operation, making it particularly suitable for public buildings with high requirements for a quiet environment. The motor is selected from high-efficiency, energy-saving three-phase asynchronous motors or permanent magnet synchronous motors, with energy efficiency ratings of IE3 or IE4. This significantly reduces operational power consumption while ensuring high output power, and the intelligent soft-start device prevents startup impacts from damaging the power grid and equipment. The control system serves as the “brain” of the entire system, with its core comprising a PLC controller and a touchscreen operation terminal. It features a switchable Chinese/English interface, historical data query functionality, and remote communication capabilities, enabling data interoperability with building fire control systems. The system supports communication protocols such as RS485, Modbus, and Profibus, enabling remote monitoring of pump group operational status, startup records, fault alarms, and maintenance reminders, providing robust support for smart fire protection systems. This constant-pressure system also supports a one-active-one-standby or one-master-multiple-standby configuration. When the main pump is operating, the standby pump remains in standby mode. If the main pump malfunctions, the control system automatically switches to the standby pump, ensuring seamless transition and uninterrupted operation, thereby enhancing the system’s redundancy and reliability. In terms of energy efficiency, the system’s built-in variable frequency drive adjusts speed based on real-time flow requirements, enabling demand-based water supply and significantly reducing energy consumption. According to test data, the average annual energy savings rate can exceed 30%, making it particularly suitable for locations requiring prolonged standby operation. The electric constant-pressure fire pump system has obtained CCC certification and can be customized according to international standards such as NFPA 20, aligning with fire safety regulations in multiple countries. The system’s overall structure adopts a modular design, with pre-set anchor holes on the base for easy on-site installation. It features a compact design and minimal footprint, making it suitable for projects with limited equipment room space. Additionally, the entire system is pre-tested and pressure-calibrated before shipment, allowing users to connect power and piping networks for immediate operation, significantly reducing construction timelines and installation/commissioning workloads. From an operational maintenance perspective, the system is equipped with multiple pressure sensing ports and operational status indicator lights. Maintenance personnel can quickly monitor the system’s current operational status and parameters via the control cabinet screen. The system also features a USB data export function for convenient maintenance record archiving. Furthermore, the system can be integrated with auxiliary devices such as automatic air release valves, pressure relief valves, and pressure stabilizing tanks to effectively control system pressure fluctuations and extend the lifespan of the piping system. In high-density urban areas or special fire protection scenarios, such as data centers, petrochemical warehouses, underground fuel tank areas at airports, and electrical switchgear stations, this type of constant-pressure system, with its technical advantages of high safety, high automation, and high reliability, is an ideal choice for ensuring the continuity and stability of fire protection water supply. Its precise constant-pressure output characteristics not only effectively support the instantaneous water spray response of dry systems but also ensure the constant-pressure maintenance of wet systems, effectively reducing system startup frequency and vibration impacts, thereby enhancing the overall lifespan of the fire protection system. In summary, the electric constant-pressure fire pump system, with its efficient startup response capability, intelligent constant-pressure control, system redundancy design, energy-saving operation advantages, compatibility with international standards, and convenient maintenance characteristics, has become the preferred solution for upgrading and renovating fire protection water supply systems in modern buildings. Its performance directly impacts the efficiency of initial fire suppression and the overall safety level of buildings, making it a critical device for achieving “rapid response, precise water supply, and intelligent control.” It will play an increasingly important role in future smart city and green building fire protection systems.