UL,FM controller for fire pump

Electric fire pump controllers are designed to start an electric motor driven fire pump.Diesel engine fire pump contollers are designed to automatically start a diesel engine driven fire pump upon detection of a pressure drop in the fire protection system.

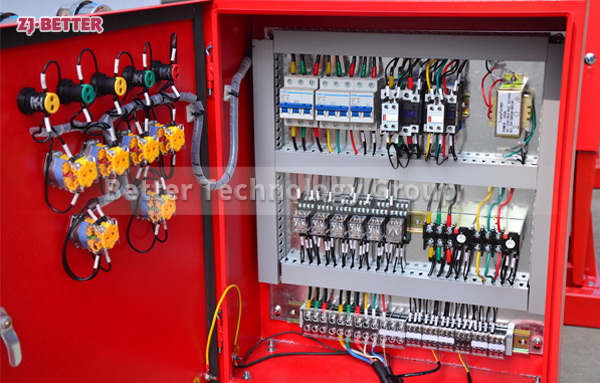

Electric fire pump controllers are designed to start an electric motor driven fire pump. It can either start the fire pump manually through the local start pushbutton or automatically through the sensing of a pressure drop in the sprinkler system. The fire pump controller is supplied with a pressure transducer. The fire pump can be stopped manually with the local stop pushbutton or automatically after the expiration of a field programmable timer. In both cases, stopping is only allowed if all starting causes have disappeared.

Diesel engine fire pump contollers are designed to automatically start a diesel engine driven fire pump upon detection of a pressure drop in the fire protection system. A diesel engine fire pump controller provides automatic & manual starting and stopping. An automatic start is contolld by a pressure transducer or by remote automatic devices such as a deluge valve. A manual start is contrlled by remote manual button or by controller pushbutton.

The automatic shutdown option provides a 30-minute automatic stop after automatic start once all starting causes have returned to nomal. The diesel engine fire pump controller includes two battery chargers to ensure the engine batteries are continuously charged.