Five reasons why the temperature of the diesel engine fire pump is too high

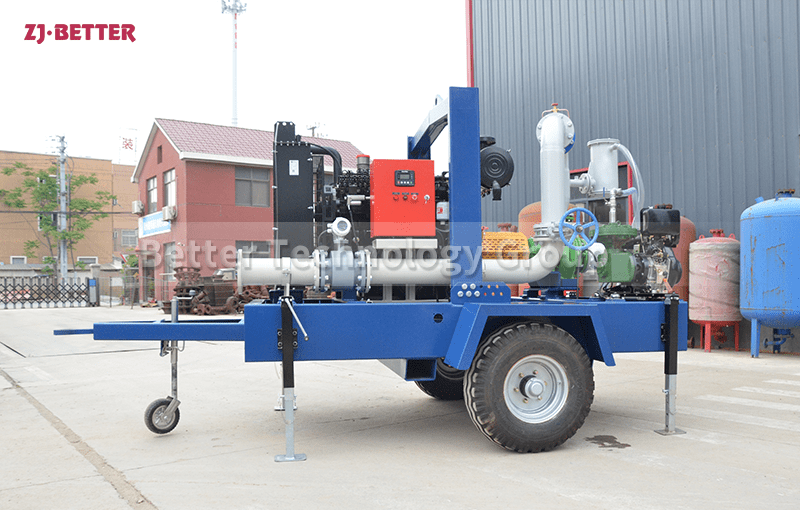

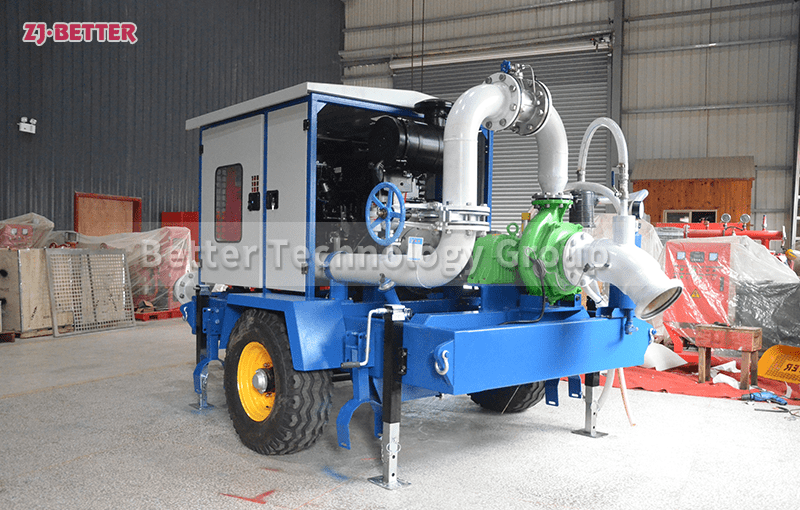

Diesel engine fire pumps can be divided into self-priming type, centrifugal type and double-suction type products. The self-priming type is mainly used for liquids with a relatively low level of suction, such as stagnant water in sewers and under bridges. Currently, diesel engines Self-priming pumps are widely used in urban flood control and emergency rescue. Centrifugal pumps are divided into two types: single-stage centrifugal pumps and multi-stage centrifugal pumps.

Diesel engine fire pumps can overheat for several reasons:

1: The diesel engine fire pump is overloaded. Therefore, in the operation of the fire pump, the high-speed and overload operation of the diesel engine must be avoided.

2: The oil radiator of the diesel engine fire pump is blocked by foreign matter, resulting in poor heat dissipation;

3: The position of the oil temperature adjustment switch of the diesel engine fire pump is incorrect. In summer, the oil will not dissipate heat through the radiator;

4: The cylinder of the diesel engine fire pump leaks, high-temperature gas enters the oil pan, and heats the oil in the oil pan.

5: The cooling fan speed of the air cooler of the diesel engine fire pump is too low, which reduces the cooling intensity and increases the body temperature of the diesel engine.

.jpg)