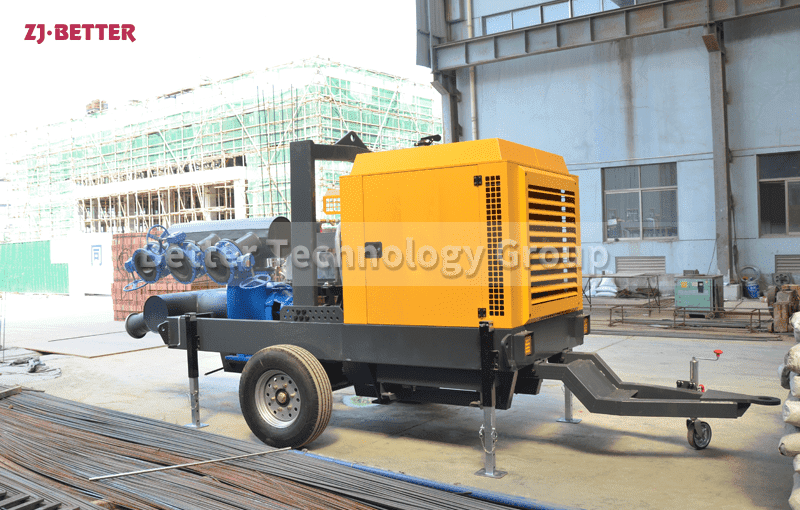

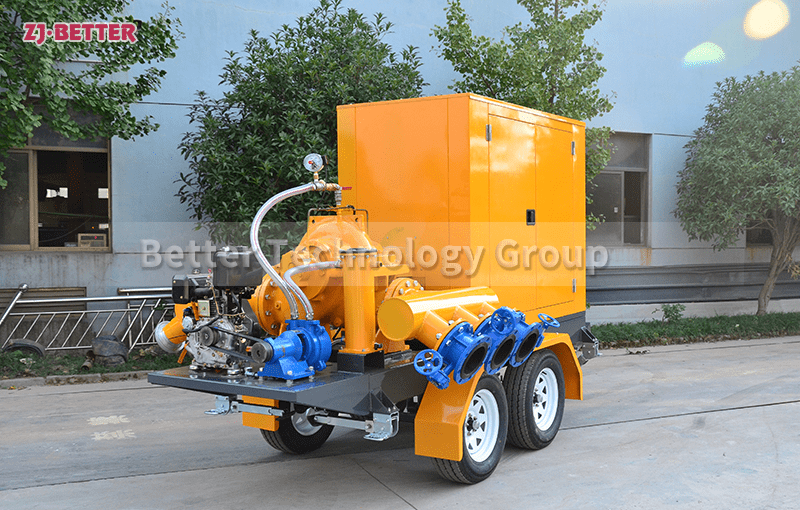

High Mobility Meets Strong Power: Outstanding Performance of Mobile Diesel Fire Pump Unit

Mobile diesel fire pump units combine high mobility with strong power, enabling fast deployment and stable long-term water supply. Ideal for urban firefighting, chemical plants, ports, mining areas, and flood control, providing reliable support for emergency response.

Mobile diesel engine fire pump units, an indispensable component of modern firefighting equipment, combine high mobility and powerful power, providing strong support for firefighting and rescue operations in a variety of complex environments. These units, designed for trailer or vehicle installation, enable rapid deployment and flexible relocation, free from the constraints of a fixed installation location. They are particularly suitable for emergency firefighting operations across multiple regions, in temporary or complex locations. Compared to traditional fixed fire pumps, mobile diesel engine fire pump units offer significant advantages in emergency response speed, flexible dispatch, and stable power output, making them an ideal choice for a variety of scenarios, including industrial parks, warehousing and logistics centers, airports and ports, chemical parks, mining areas, and municipal emergency water supply. Their greatest strength lies in their combination of mobility and power, enabling rapid on-site deployment while maintaining efficient operation in harsh environments. Powered by a diesel engine, these units ensure independent operation without relying on an external power system. They maintain robust water supply even during power outages or power outages, making them irreplaceable for critical firefighting and rescue operations. Diesel engines offer powerful output torque and continuous operation, driving fire pumps to maintain stable high-flow and high-lift operations, meeting the continuous water supply requirements of large-scale firefighting. Mobile fire pump units are designed for compactness and durability, featuring a high-strength chassis and frame, coupled with a two- or four-wheel trailer structure to ensure stable mobility in all terrains. The trailer’s quick-connect and detach feature allows for quick transfer and deployment, significantly improving emergency response efficiency. In fire emergencies, time is of the essence, and mobile diesel fire pump units, with their flexible dispatch capabilities and rapid commissioning, can safeguard precious time windows and enhance firefighting efficiency. In addition to their maneuverability and power, these fire pump units also offer numerous performance advantages. The pump unit utilizes a highly efficient hydraulic model, capable of delivering high-flow water under high pressure, meeting the demands of high-rise buildings, long-distance water delivery, or complex fire scenes. Select models are equipped with automated control systems and intelligent monitoring devices, providing real-time display of operating parameters such as pressure, flow, and speed. They also include fault alarms and self-protection features, enhancing operational safety and reliability. For firefighters, this intelligent functionality significantly simplifies operation, enabling faster and safer deployment. Mobile diesel fire pump sets have a wide range of applications. Within urban firefighting systems, they effectively supplement fixed fire pump rooms, particularly in the event of a large fire or water supply system failure. Mobile pump sets can quickly fill in and provide a continuous water supply. In high-risk locations such as chemical parks, oil depots, and ports, their high power and flexibility make them a reliable choice for emergency response. In specialized environments such as mountainous areas, mining areas, and construction sites, where traditional fire water supply facilities are difficult to reach, mobile diesel fire pump sets demonstrate unique application value, ensuring rapid water delivery to the fire front. Their flexibility extends beyond firefighting and rescue operations, also serving applications such as flood control and drainage, and temporary water supply, making them versatile emergency equipment. Performance stability is another key advantage of these products. Diesel engines offer high durability and environmental adaptability, enabling stable operation in harsh conditions such as high and low temperatures, high humidity, and heavy dust. Its scientifically designed fuel supply system delivers high combustion efficiency and relatively low fuel consumption, reducing operating costs. Furthermore, the equipment’s maintenance has been optimized, with compact core components facilitating daily inspection and maintenance. This ensures the equipment remains in optimal working condition over the long term, reducing the risk of downtime due to breakdowns. Mobile diesel fire pump units also offer advantages in transportation and storage. Their corrosion-resistant frame is treated for superior weather resistance, allowing them to be stored outdoors for extended periods without damage. Some units feature protective casings or silent covers, extending the life of the equipment while reducing noise levels during operation and enhancing user comfort. This design not only meets the environmental and noise requirements of modern urban firefighting, but also demonstrates user-friendly considerations in every detail. In summary, the mobile diesel fire pump unit, with its perfect combination of high mobility and high power, demonstrates its irreplaceable value in emergency firefighting and diverse applications. It is not only a reliable firefighting and water supply system, but also a vital component in ensuring social security and emergency response capabilities. From rapid response to continuous water supply, from complex environments to multifunctional applications, these devices, with their powerful performance and exceptional flexibility, have injected new vitality and security into modern firefighting systems. As future firefighting equipment continues to evolve toward intelligent and efficient development, mobile diesel fire pump sets will undoubtedly play an even more crucial role, becoming an indispensable core force in various emergency scenarios.