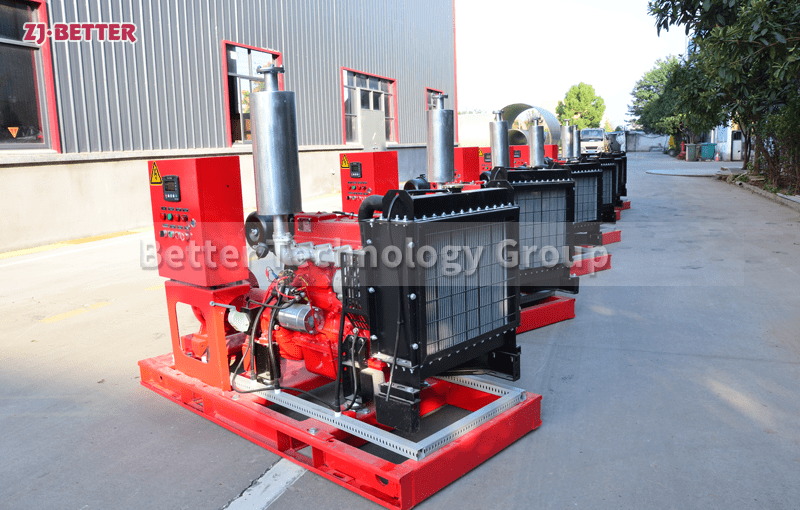

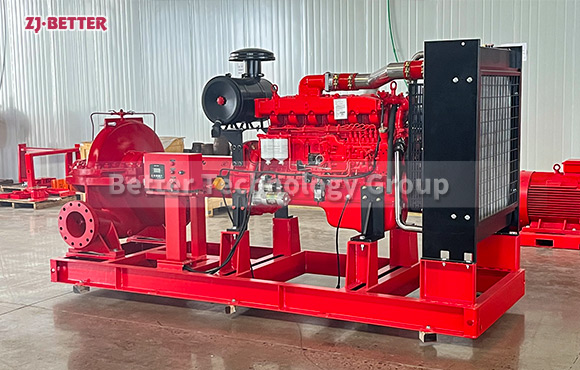

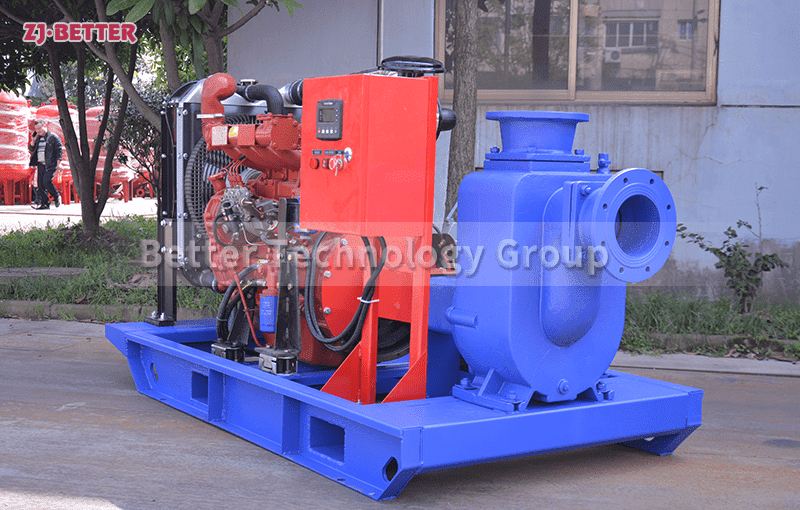

High cost performance of diesel engine fire pump

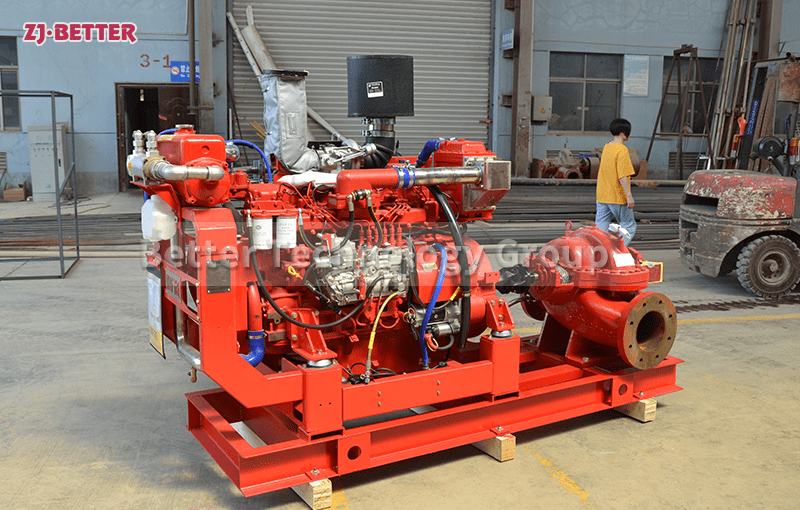

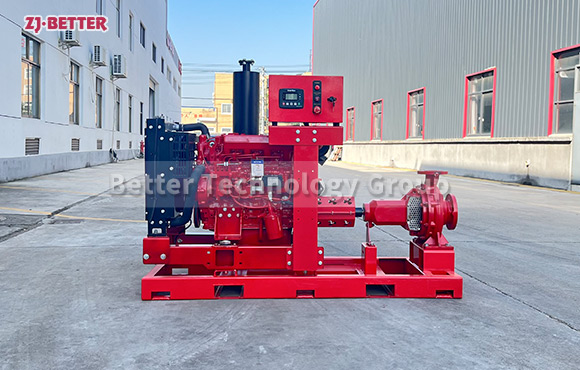

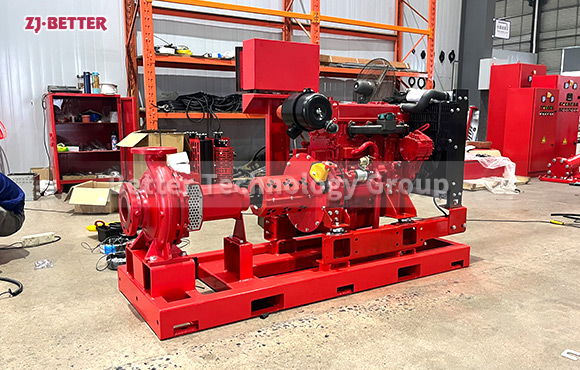

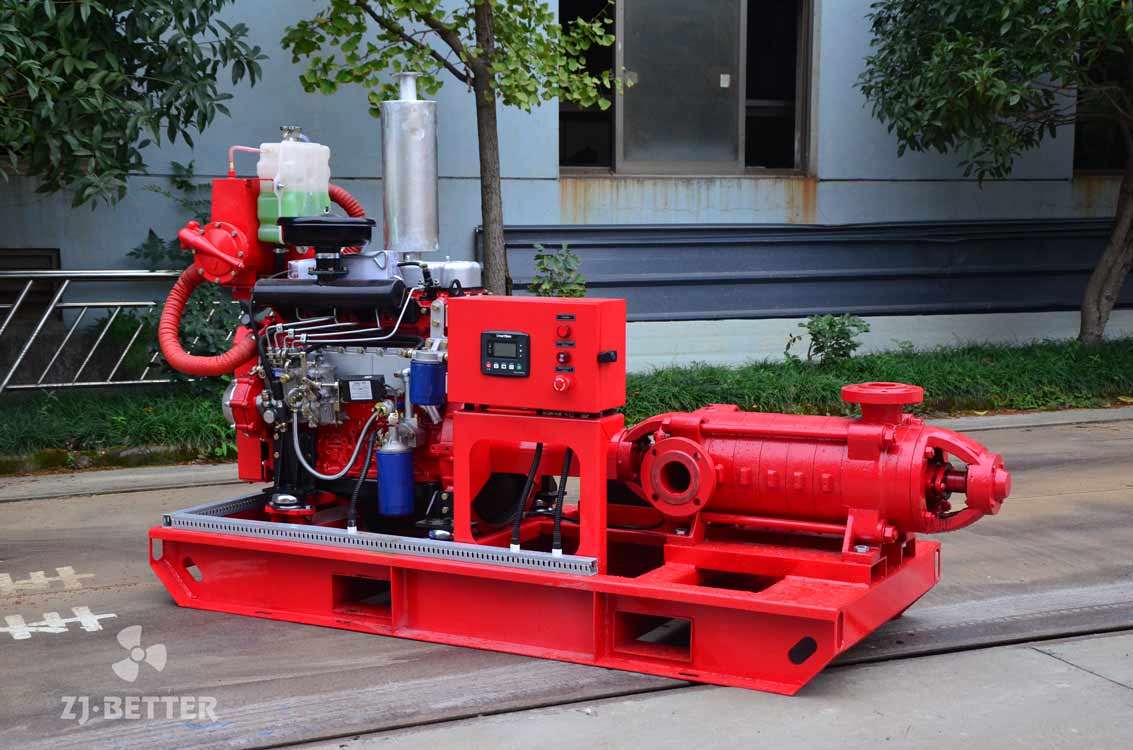

Diesel engine fire pump has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. This diesel engine pump set can transport clean water or other liquids whose physical and chemical properties are similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump’s flow parts, sealing form and adding a cooling system.

Diesel engine fire pumps are often used for emergency water supply in high-rise buildings, water companies, steel plants, wineries, chemical plants, hotels, hospitals, and other large-scale projects. Diesel engine fire pump is suitable for unattended emergency water supply system. The product has the characteristics of advanced technology, high degree of automation, superior performance, complete protection functions, reasonable structure, simple installation, and high cost performance. net pressure. Diesel engine fire pumps are selected according to different working conditions: single-stage single-suction centrifugal pumps, high-pressure multi-stage pumps, double-suction split pumps, etc.