The core of diesel engine fire pump: the working principle of diesel engine

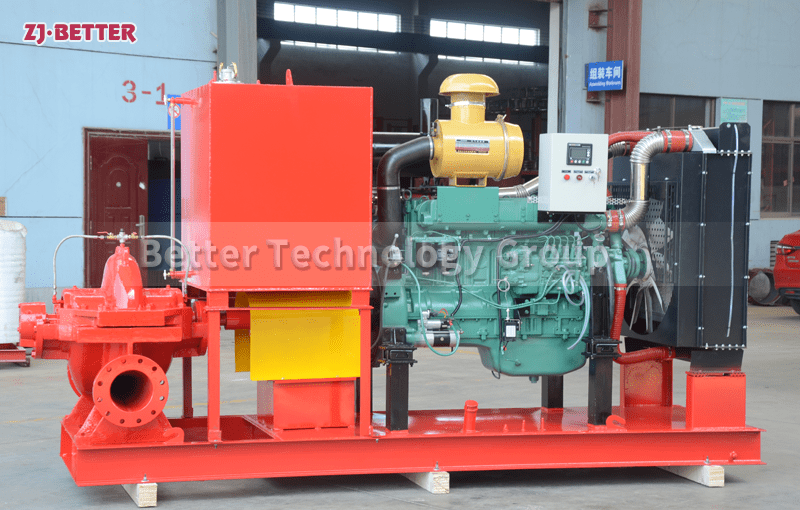

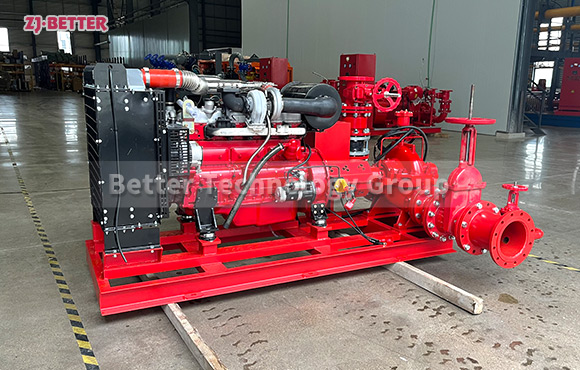

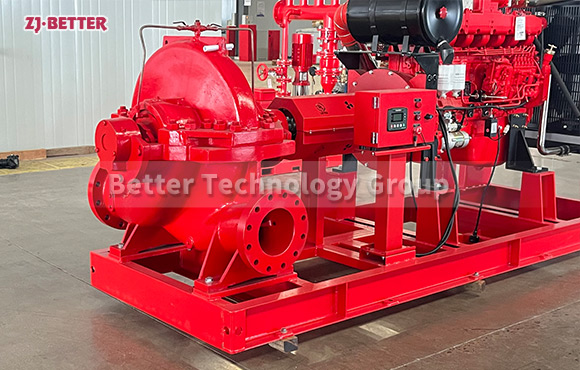

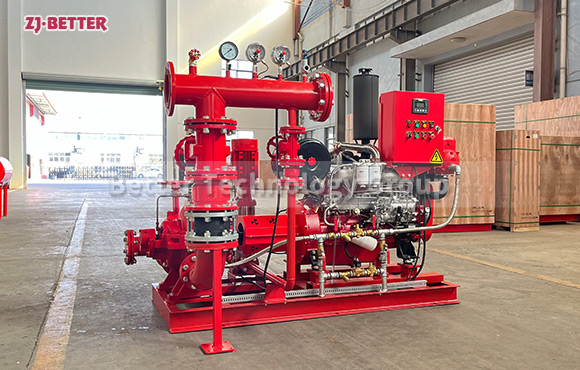

Diesel engine fire pumps are different from traditional fire pumps in that they cover a wide area and have a large spray force. Naturally, the equipment and technology must be more prominent. At present, there are not many manufacturers who can apply the working principle of diesel engine to the design of diesel engine fire pump, adhere to the principle concept, and can perfectly integrate the assembly of other parts of diesel engine fire pump.

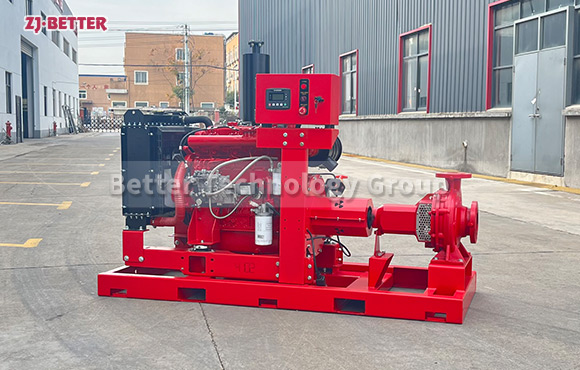

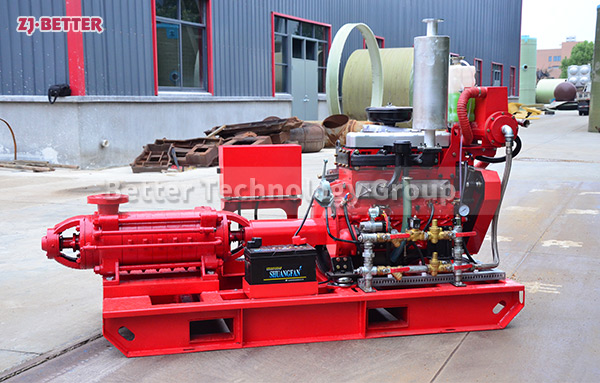

Better Technology Co., Ltd., a joint-stock enterprise specializing in the design, development, manufacture and sales of general fluid equipment, has introduced a high-level design,development and enterprise management mode, and has hired foreign experts to provide technical guidance for the company for a long time. The products are competitive.

Working principle of diesel engine

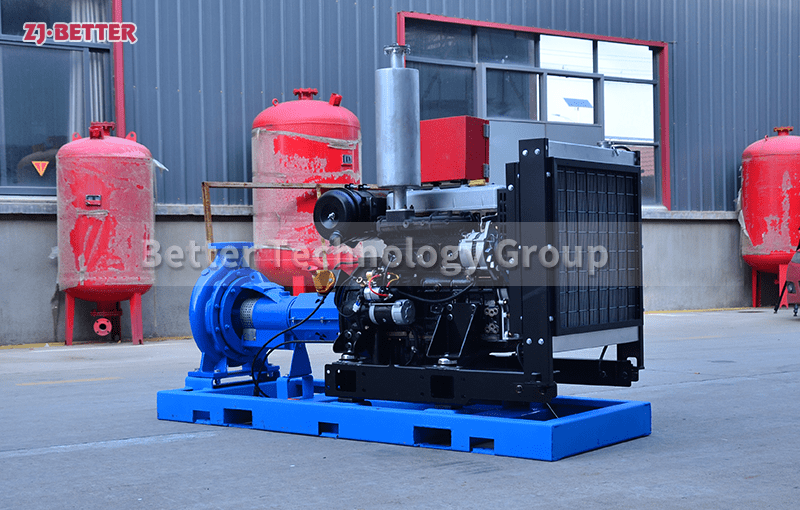

During the working process of a diesel engine, each working cycle also undergoes four strokes of intake, compression, power, and exhaust. However, since the fuel used in the diesel engine is diesel oil, its viscosity is higher than that of gasoline, it is not easy to evaporate, and its auto-ignition temperature is lower than that of gasoline, so the formation and ignition of combustible mixtures are different from those of gasoline engines.

The diesel engine inhales pure air during the intake stroke, and uses the air to change the pressure to generate power. When the compression stroke is near the end, the diesel fire pump will increase the oil pressure to above 10MPa, spray it into the cylinder through the injector, and mix it with the compressed high-temperature air in a short time to form a combustible mixture. Due to the high compression ratio of the diesel engine (generally 16-22), the air pressure in the cylinder can reach 3.5-4.5MPa at the end of the compression, and the temperature can reach as high as 750-1000K (while the gas mixture pressure of the gasoline engine at this time will be 0.6-1.2MPa , the temperature reaches 600-700K), which greatly exceeds the self-ignition temperature of diesel. For this reason, after the diesel fuel is injected into the cylinder, it will ignite and burn by itself immediately after mixing with the air in a very short time. The air pressure in the cylinder rises rapidly to 6-9MPa, and the temperature also rises to 2000-2500K. Pushed by the high-pressure gas, the piston moves downward and drives the crankshaft to rotate to do work, and the exhaust gas is also discharged into the atmosphere through the exhaust pipe.