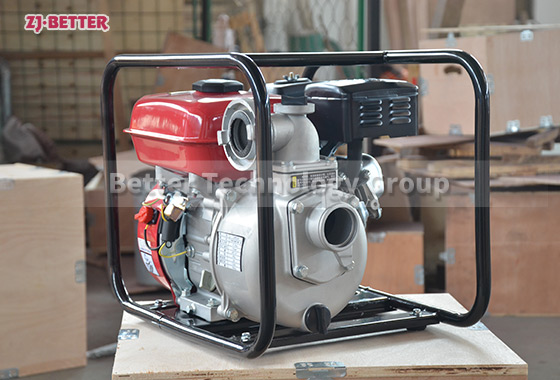

In emergency scenarios, a stable and reliable fire protection system is the final safeguard for life and property. The diesel engine fire pump stands out as a power-independent solution, performing exceptionally in situations where electricity is unavailable or unreliable.

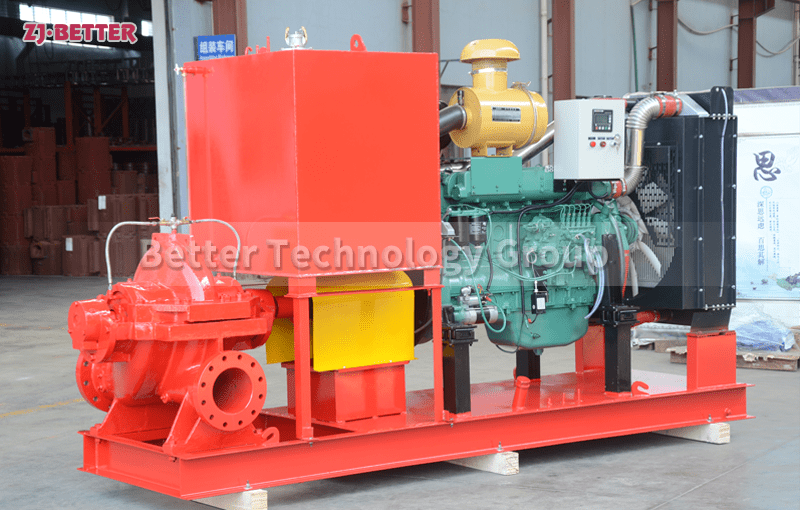

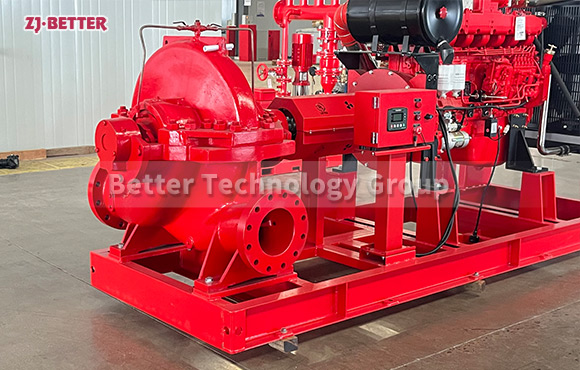

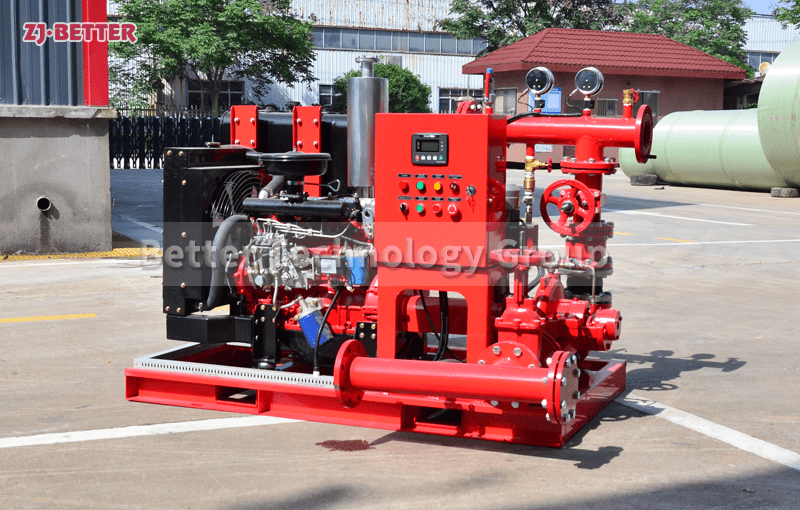

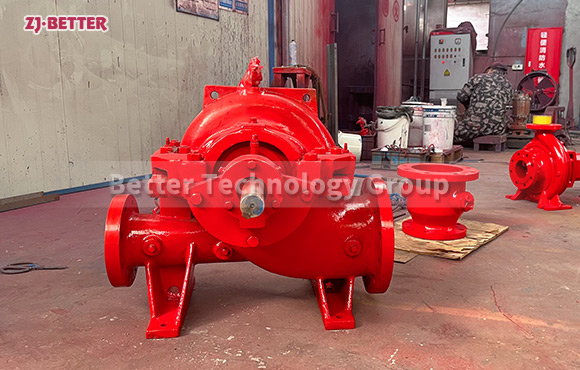

Equipped with a high-power diesel engine, this pump delivers consistent water supply even during blackouts or in remote areas. Its compact design and flexible installation make it ideal for high-rise buildings, petrochemical plants, energy facilities, and large warehouses.

Engineered for high head, large flow, and operational efficiency, the system integrates intelligent features such as automatic start, alarm linkage, and self-diagnosis for enhanced emergency response and operational safety.

Whether as a primary fire system or a backup unit, this high-performance diesel fire pump is your most dependable partner when facing unpredictable fire risks.