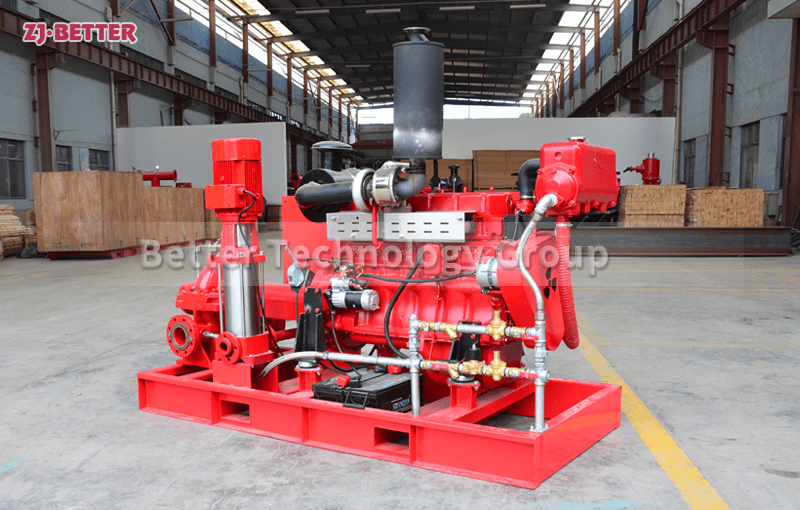

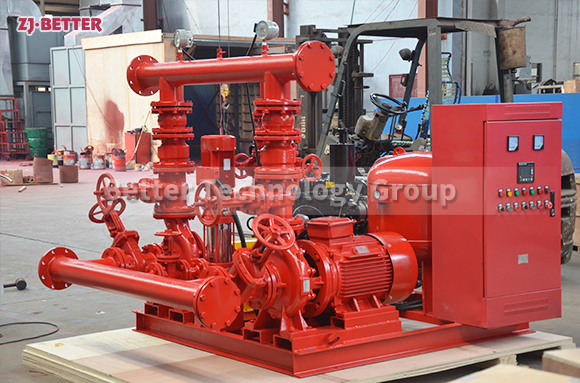

Diesel Engine Self-priming Fire Pump Manufacturer

Self-priming fire pump is a mechatronics equipment researched and developed according to the provisions of my country’s fire regulations and the different requirements of various users. The product is innovative, advanced and practical. It simplifies the design of the pump room. The underground pump room can be changed to the ground, which is convenient for construction and saves investment; the outdoor pool can also be used to meet the requirements of use; the self-priming function can be used to make the fire pool deeper. To 3-6m, under the same effective volume, the land area occupied by the pool is much smaller than the original, which saves land, facilitates construction, reduces construction costs, and greatly saves investment; it can work under the condition of negative water level and meet the requirements in time. Fire protection requirements; the self-priming fire pump can discharge water in time to rescue and extinguish fires in time; it has a strict and reliable automatic circuit detection function, so that the unit is usually in a quasi-fire-fighting state.

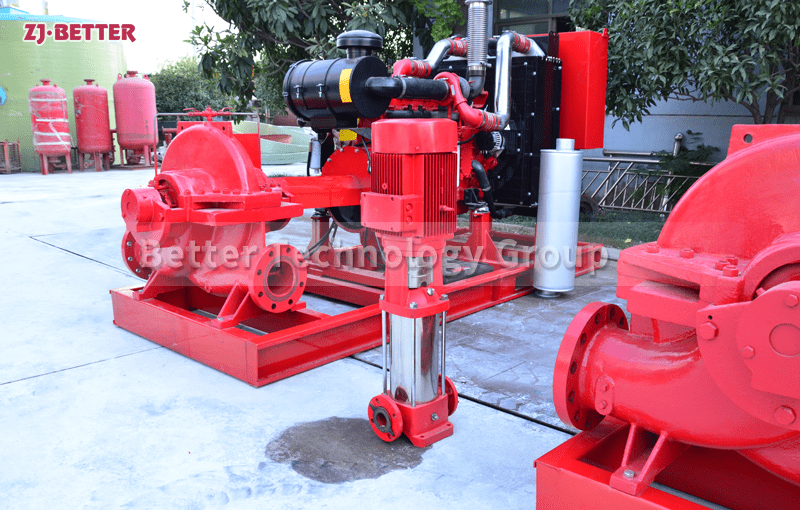

1. The mechanism is compact, small in size and beautiful in appearance. Its vertical mechanism determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the running stability and service life of the pump;

2. The suction port and discharge port of the fire pump are horizontal, which simplifies the connection of the pipeline;

3. According to needs, the suction port and the discharge port can be installed in the same direction or in several different directions of 90°, 180°, and 270° to meet different connection occasions;

4. The pump pressure can be satisfied by increasing or decreasing the number of pump stages and cutting the outer diameter of the impeller as required, without changing the installation area, which is not available in other pumps;

5. The rotor of the self-priming fire pump has a small winding, stable operation, low vibration, low noise and long service life.