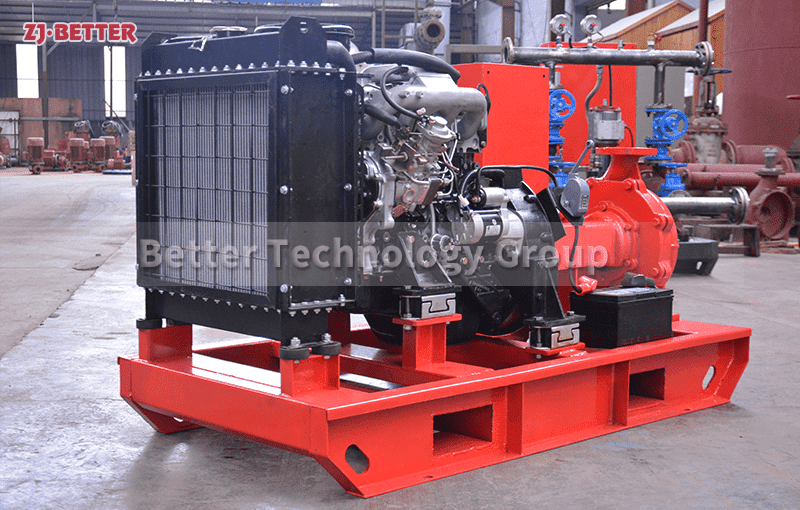

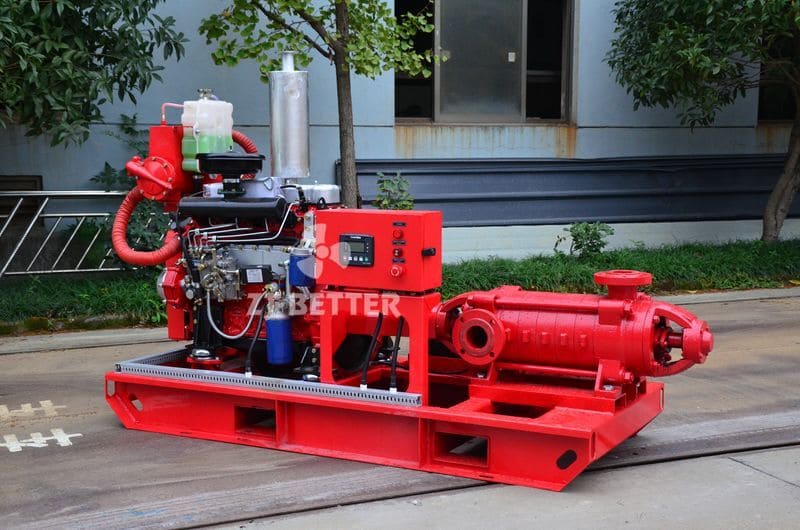

Single Cylinder Diesel Self-Priming Fire Pump: Rapid and Reliable Fire Protection Solutions

Ensure rapid and reliable fire protection with the Single Cylinder Diesel Self-Priming Fire Pump. This advanced pump offers automatic startup within 15 seconds of receiving fire signals, guaranteeing immediate response. Its automatic charging system ensures smooth operation, while built-in alarms and protections provide enhanced safety. With automatic preheating and a direct connection design, this pump is both efficient and reliable. It is suitable for various applications in areas where firefighting vehicles face limitations. The Single Cylinder Diesel Self-Priming Fire Pump is ideal for areas where access by firefighting vehicles is limited, such as small towns, industrial ports, and rural areas.

When it comes to fire emergencies, every second counts. That’s why you need the Single Cylinder Diesel Self-Priming Fire Pump, a cutting-edge solution designed to provide rapid response and reliable performance. Let’s explore its remarkable features:

- Automatic Startup: In just 15 seconds, this fire pump automatically starts and operates at full capacity upon receiving signals such as fire alarms, pipe network pressure changes, power outages, or other start-up triggers. You can trust it to kick into action swiftly, ensuring immediate fire suppression.

- Automatic Charging: The built-in battery of this fire pump can be conveniently charged by either mains electricity or the diesel engine itself. This ensures a seamless startup process, guaranteeing the smooth operation of the unit when you need it most.

- Automatic Alarms and Protections: Equipped with intelligent alarm systems, this pump provides automatic alerts for low oil pressure, high water temperature, and other potential faults. In case of overspeed, it triggers an alarm and shuts down to safeguard the engine. These features enhance safety and prevent damage to the equipment.

- Automatic Preheating: The Single Cylinder Diesel Self-Priming Fire Pump keeps the engine in a preheated standby state, ready to spring into action at a moment’s notice. This feature ensures reliable performance during emergencies and enables efficient emergency response.

- Direct Connection: Featuring the latest technology, this fire pump employs a direct connection method using an elastic coupling joint, linking the superior domestic diesel engine to the water pump. This design minimizes potential failure points, reduces startup time, and enhances the reliability and emergency performance of the unit. With a power rating of up to 360kW, it delivers exceptional performance you can rely on.