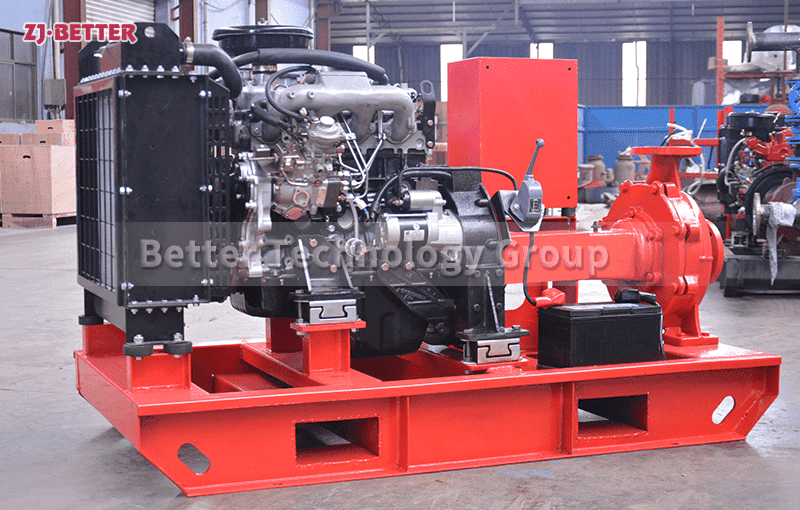

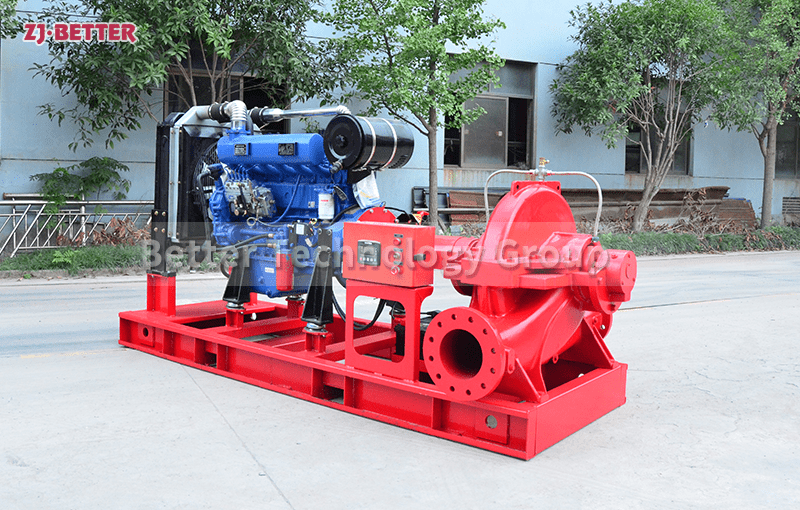

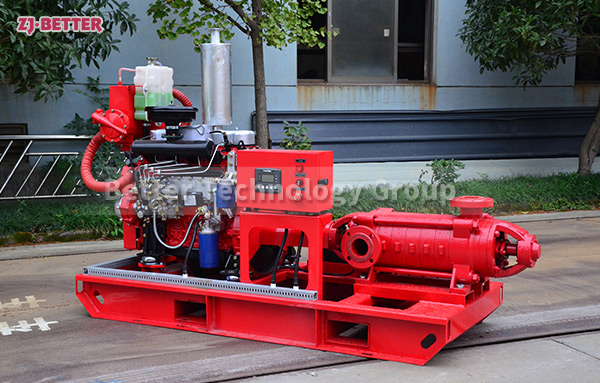

Diesel fire pump for a wide range of water supply

Diesel engine fire pump is a good water supply equipment, which is widely used in both ordinary water supply and fire water supply. As long as the appropriate model is selected to match the application, and the inspection and maintenance work is done well, the diesel engine fire pump will basically not fail. The diesel engine fire pump is highly automated, and can be equipped with different operating systems according to the needs of use. It has strong overload capacity, convenient maintenance and good starting characteristics. Since there are so many advantages in use, the daily inspection and maintenance work should be more meticulous. The daily maintenance of the diesel engine fire pump must check the fuel tank, battery, transmission connecting plate, connecting screws, check the three leaks (water, oil, gas) – check the sealing surface of the oil pipe and the water pipe joint, etc.

In order to match the service cycle of the fire pump, the inspection of the diesel engine and the fire pump should be regularly checked, and the parts to be replaced or repaired should be adjusted and corrected in a timely manner. We need to check the fuel tank reserves and oil quality of the diesel engine fire pump every day; the usage of the battery; the cooling system, etc., the pump shaft, impeller, bearing, and the wear of the water pipe and filter screen of the water pump. (Diesel engines of different brands may be different, and should be checked and maintained according to the specific model and structure of the diesel engine).