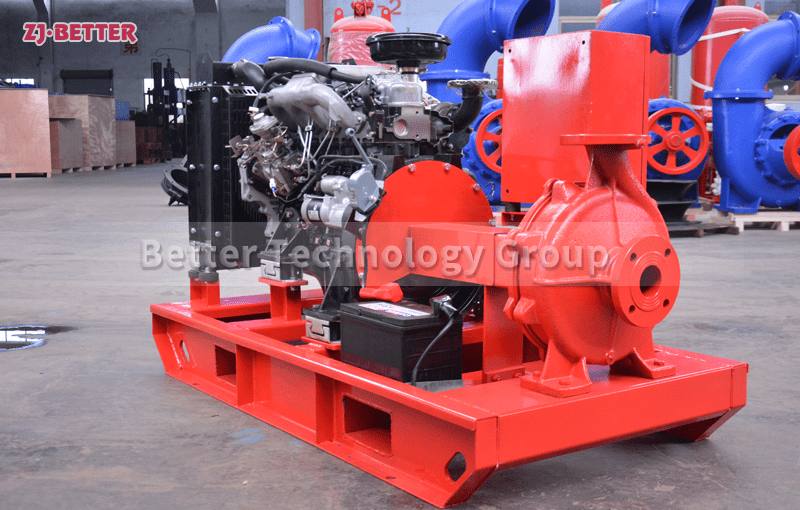

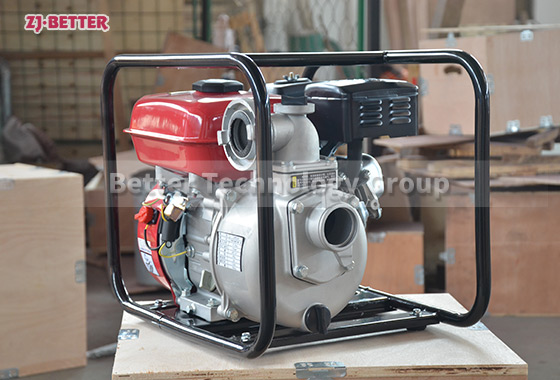

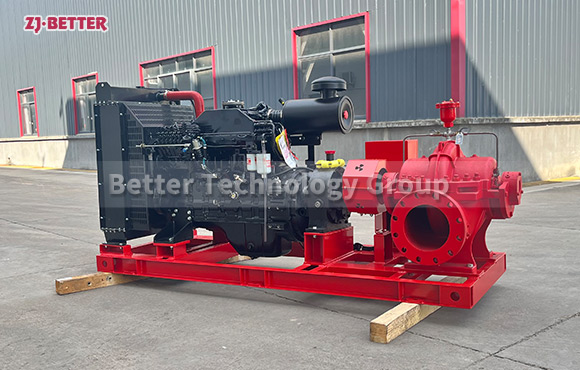

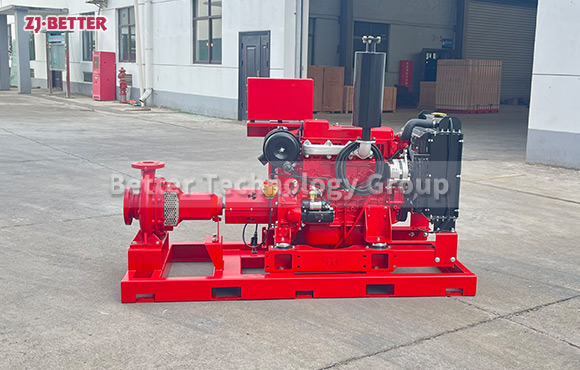

Diesel Engine Fire Pump

Diesel engine fire pump as a common must use facilities, only in the fire signal to come, and electric pump failure or power failure, diesel engine fire pump will automatically start, widely used in environmental protection, water treatment and fire departments to transport a variety of liquids.

Diesel engine fire pump product overview: The fire pump used in the diesel engine fire pump complete set can be the IS series single-stage type and D-type series segment multi-stage type produced by our company. The diesel water pumps used in this series of equipment are made of domestic or imported high-quality products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use and high degree of automation. They are advanced and reliable fire fighting equipment.