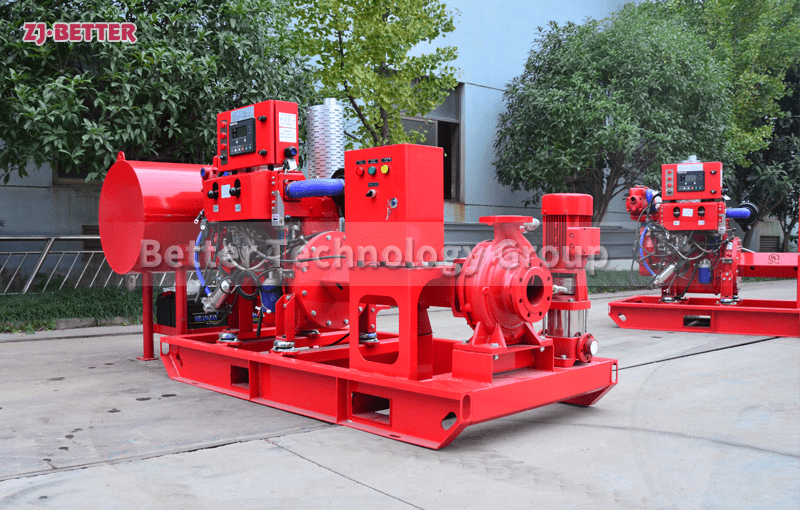

Diesel engine fire pump working range

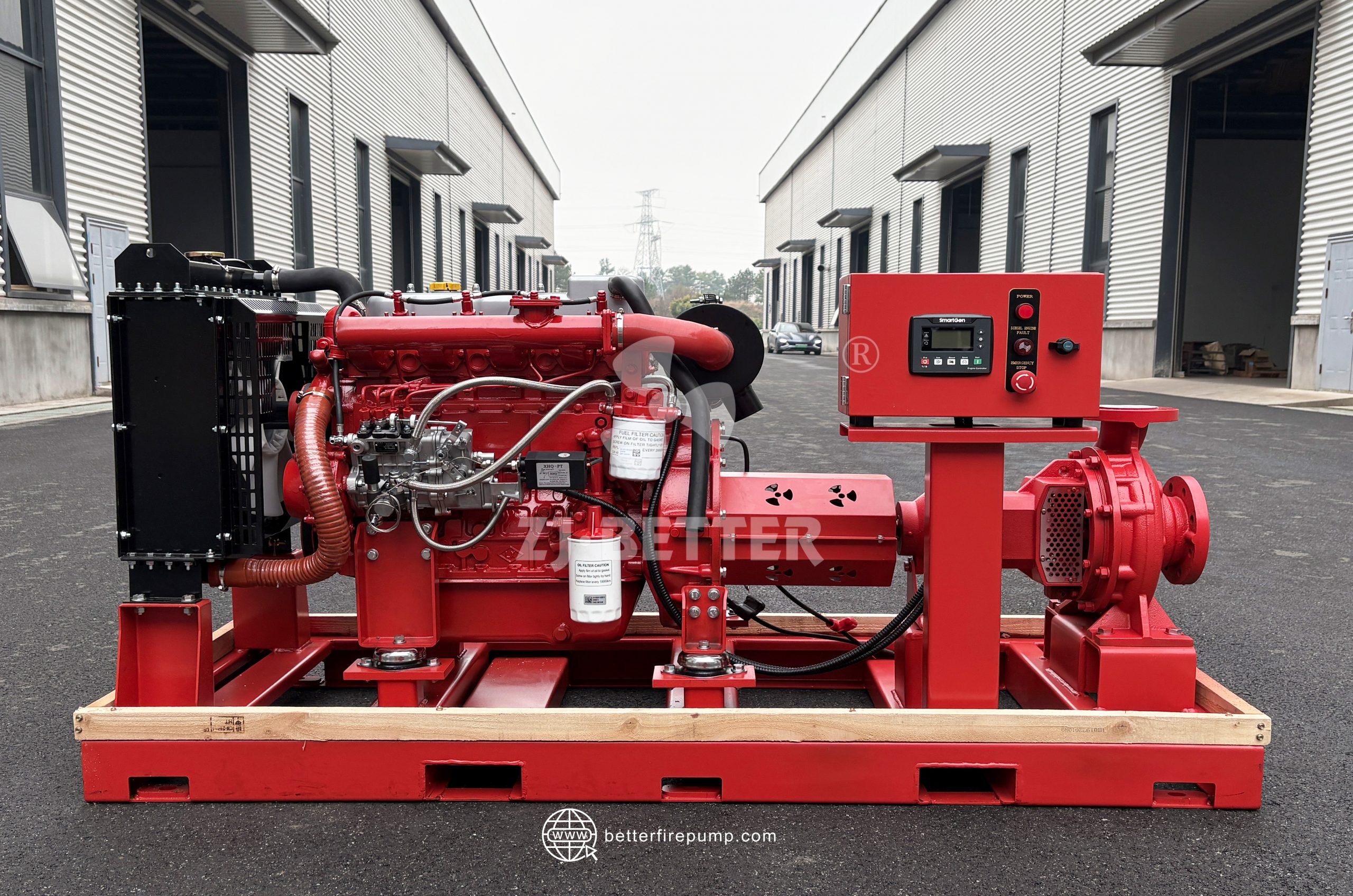

Diesel engine fire pumps are often used for emergency water supply in high-rise buildings, water companies, steel plants, wineries, chemical plants, hotels, hospitals, and other large-scale projects. The diesel emergency water supply pump set is suitable for unattended emergency water supply systems. The product has the characteristics of high automation, superior performance, complete protection functions, reasonable structure, simple installation, and high cost performance. When the factory suddenly loses power, the diesel emergency water supply pump set automatically starts to replenish pipe network pressure.

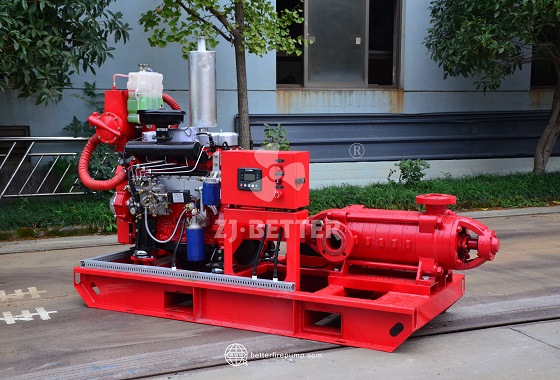

Diesel engine fire pump features:

1. High efficiency and energy saving: Using CFD to calculate fluid dynamics, analyze and calculate the relationship between pressure distribution and velocity distribution in the pump, optimize the flow channel design of the pump, ensure that the pump has an efficient hydraulic profile, and improve the efficiency of the pump.

2. Convenient installation and maintenance: vertical pipeline structure, the inlet and outlet of the pump can be installed in any position and direction of the pipeline like a valve, which is very convenient for installation and maintenance.

3. Stable operation, safe and reliable: The direct connection between the motor and the pump simplifies the intermediate transmission structure, enhances the stability of operation, and makes the unit run smoothly, safe and reliable.

4. Stainless steel sleeve: The position of the mechanical seal of the shaft is relatively easy to be corroded. Once the direct-coupled pump shaft is corroded, it is easy to cause the mechanical seal to fail. The pump here is inlaid with stainless steel sleeves to avoid corrosion, improve shaft life and reduce operation and maintenance costs.