The reliability of the diesel engine fire pump set is much higher

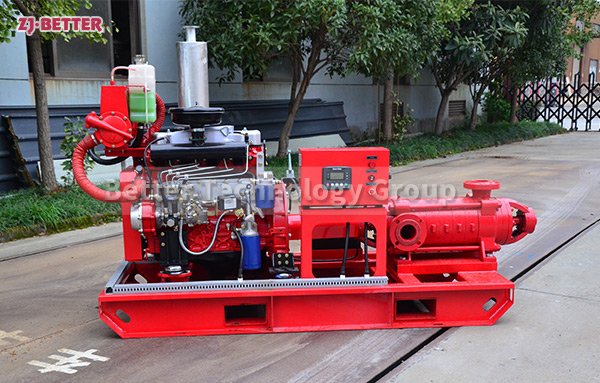

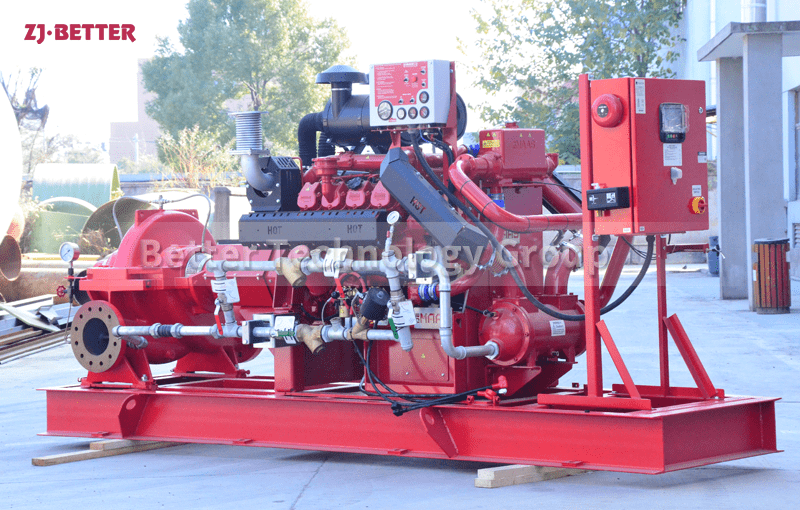

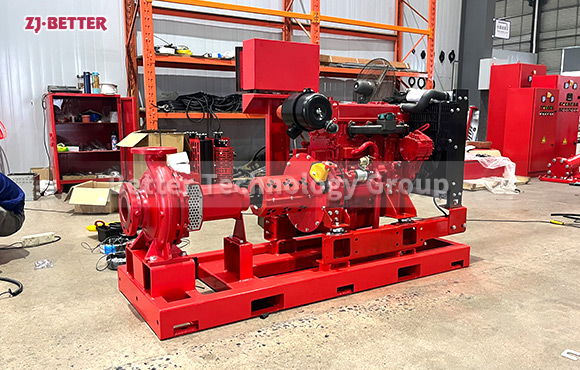

Since the diesel engine fire pump set is not limited by the power supply when equipped with a diesel engine power pump set, it can better provide safety guarantee for fire emergency. At the same time, the speed regulation function of the diesel engine makes the use and performance of the unit equipment more extensive, and the adjustable performance of pressure and flow is further improved. Equipped with well-known brand components at home and abroad, the usability and safety of the pump set are reliably guaranteed. It can fully meet various occasions of industrial and mining enterprises such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, and textiles.

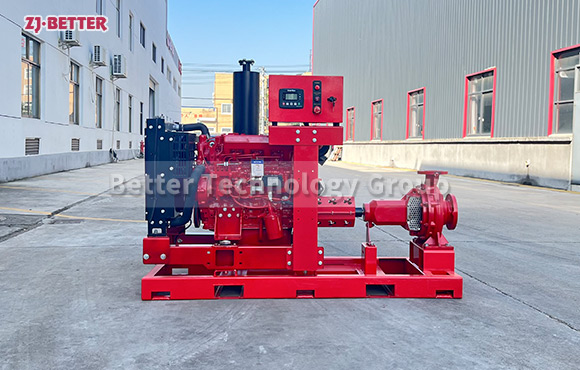

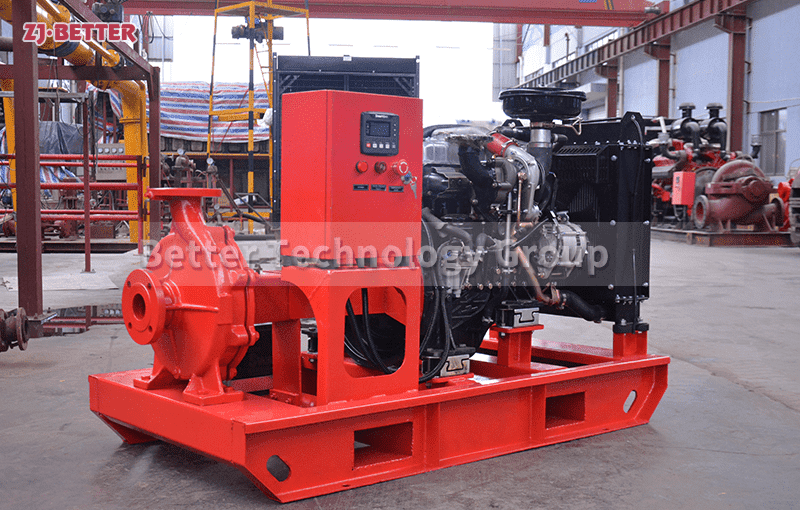

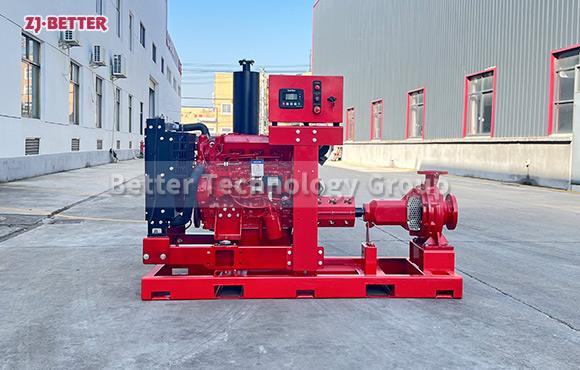

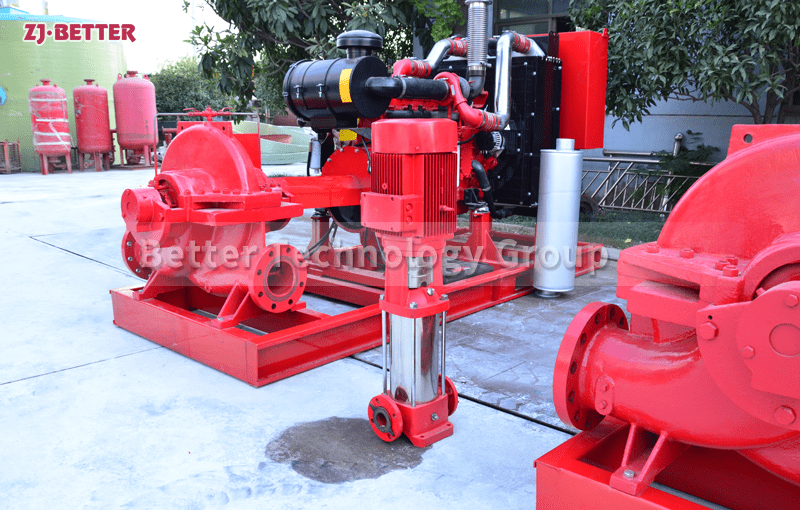

Fixed fire water supply equipment can use fire pumps driven by electric motors, or fire pumps driven by diesel engines. The international standard name of diesel engine fire pump set is “engineering diesel engine fire pump set”. It uses diesel engine as power to drive fire water pump, and outputs pressurized water or air foam mixture to carry out fire extinguishing work.

When dual power supplies are required or in order to further improve reliability, fire water supply equipment often adopts fire pumps driven by diesel engines. After the various components of the diesel engine fire pump set have passed the strict certification test and passed the test, their reliability is much higher than that of the electric motor fire pump set.