Unlocking Success with Horizontal Multistage Pumps

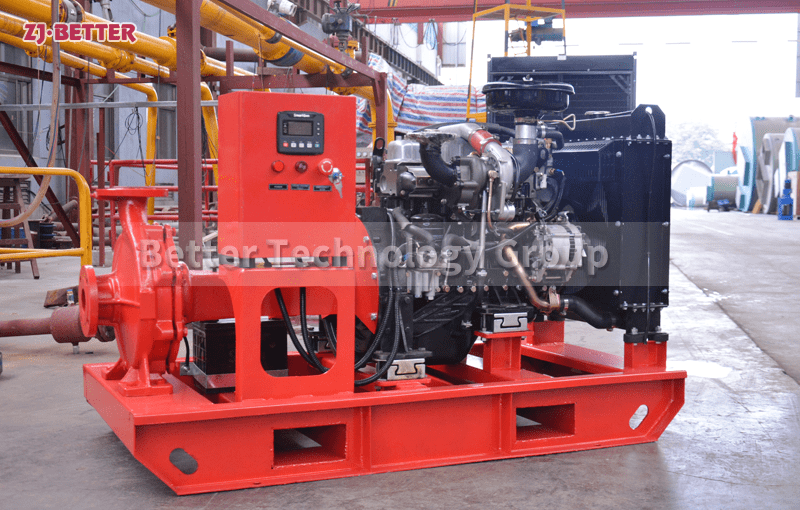

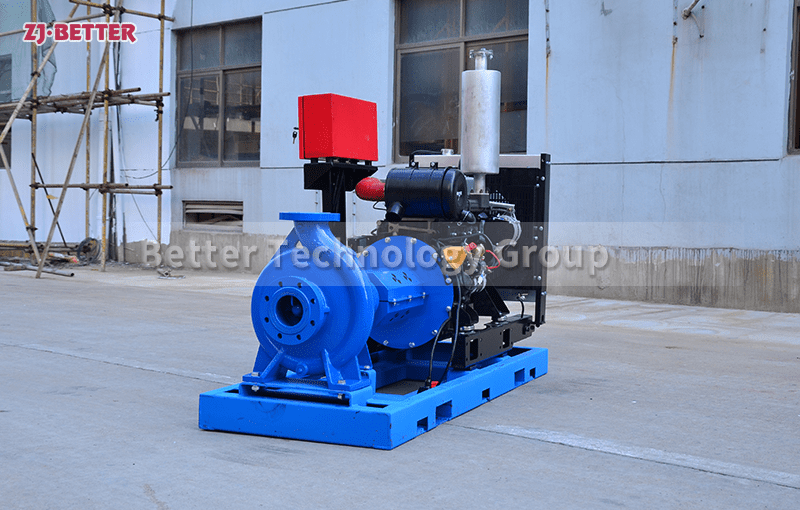

The Horizontal Multistage Pump is an exceptional engineering solution that offers high performance and reliability for fluid handling applications. With its unique multistage impeller design, it delivers efficient and incremental pressure boosting for high-pressure and high-flow scenarios. Whether used in water supply systems, industrial processes, irrigation, or building cooling, this pump ensures stable water pressure and flow.

1. High Efficiency: The multistage impeller design of the Horizontal Multistage Pump allows for incremental pressure boosting, delivering efficient pressure gain and fluid transfer. It can handle high-pressure and high-flow applications, meeting diverse needs.

2. Space Saving: The horizontal layout of the pump ensures a compact design, requiring minimal space. This makes it suitable for installation in limited spaces, facilitating integration and arrangement.

3. Stability and Reliability: Constructed with high-quality materials and precision manufacturing, the Horizontal Multistage Pump exhibits excellent durability and reliability. It can operate stably for extended periods, reducing downtime and maintenance requirements.

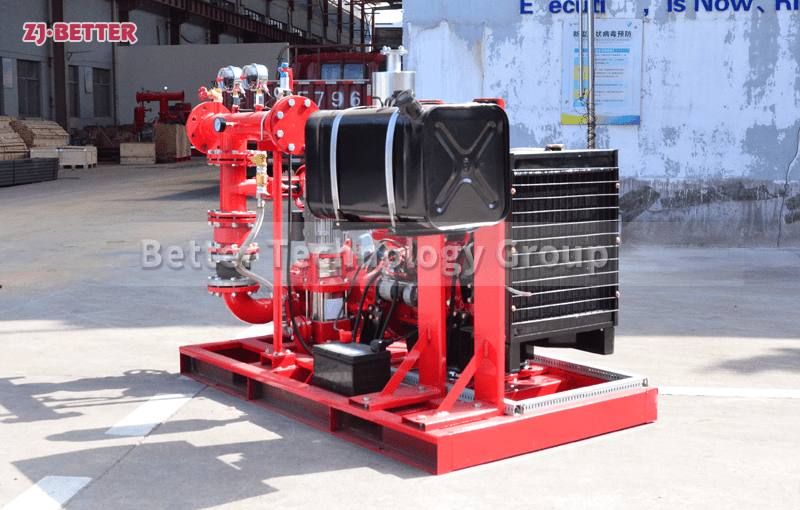

4. Versatile Applications: The Horizontal Multistage Pump finds applications in various fields including water supply systems, industrial processes, cooling systems, and thermal power generation. It can handle different fluid mediums, catering to diverse industry requirements.

5. Ease of Maintenance: The design of the Horizontal Multistage Pump facilitates convenient maintenance. The disassembly and installation of the pump body and impellers are relatively simple, reducing maintenance costs and efforts.

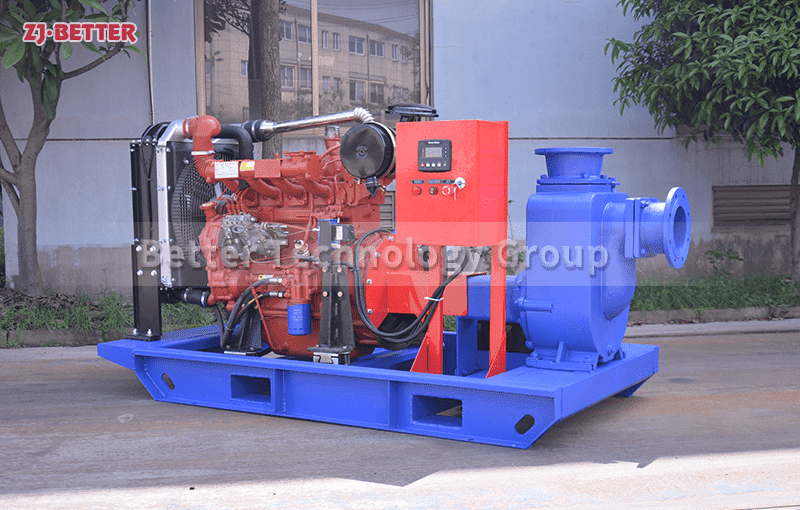

6. Energy Efficiency: With advanced design and control technology, the Horizontal Multistage Pump provides higher efficiency and energy utilization, reducing energy consumption and operational costs.

In summary, the Horizontal Multistage Pump stands out for its high efficiency, space-saving design, stability and reliability, versatile applications, ease of maintenance, and energy efficiency. It is an ideal choice for various fluid handling needs. Whether for commercial, industrial, or residential applications, the Horizontal Multistage Pump can meet your requirements and provide reliable operation for your systems.