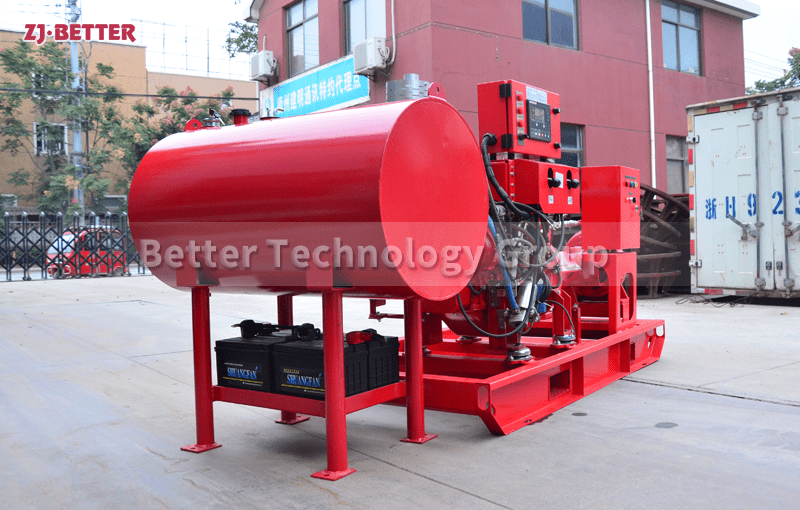

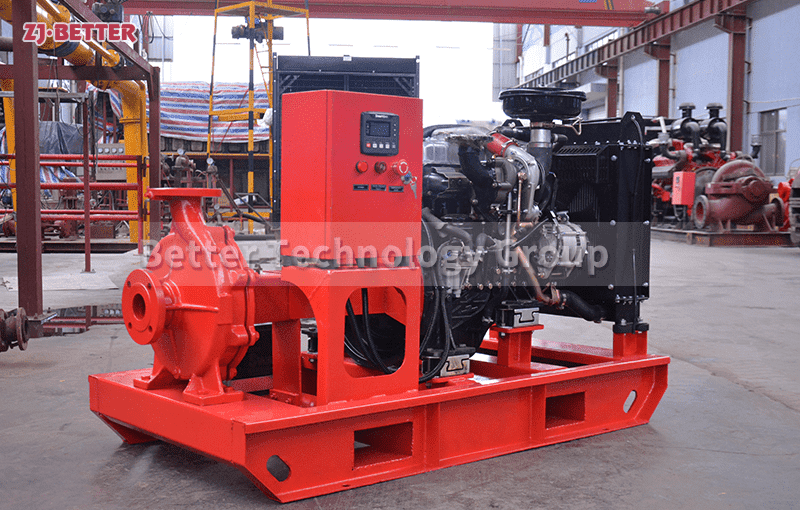

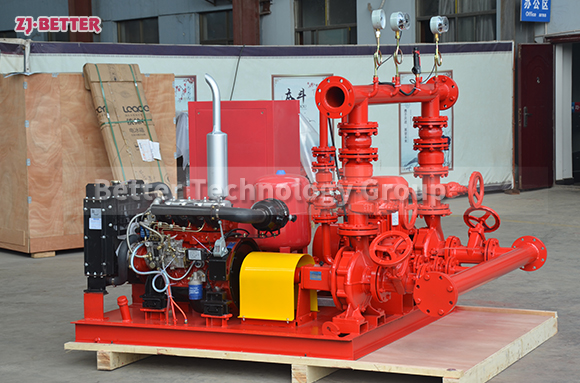

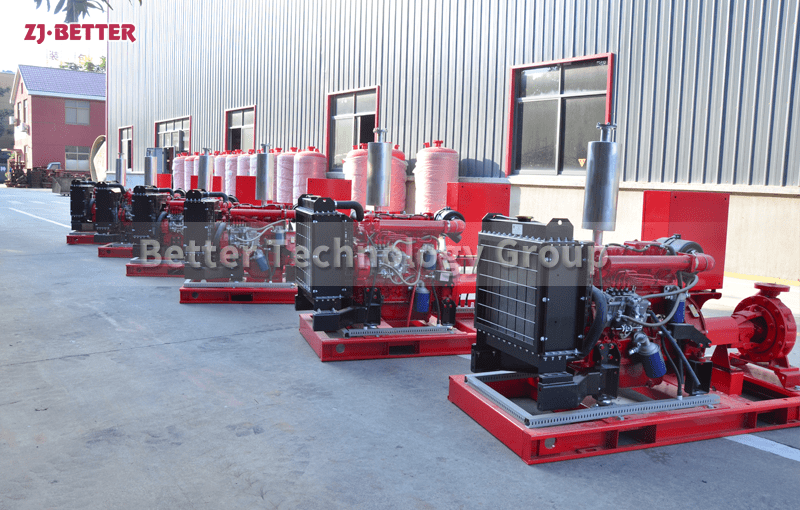

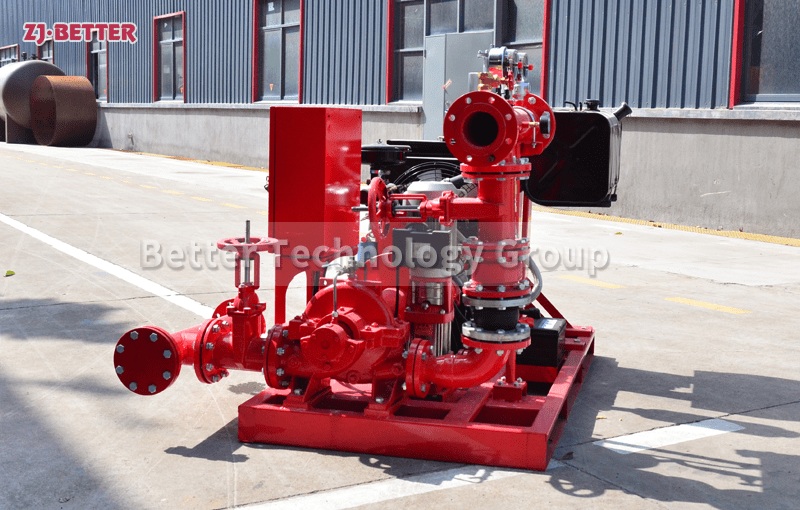

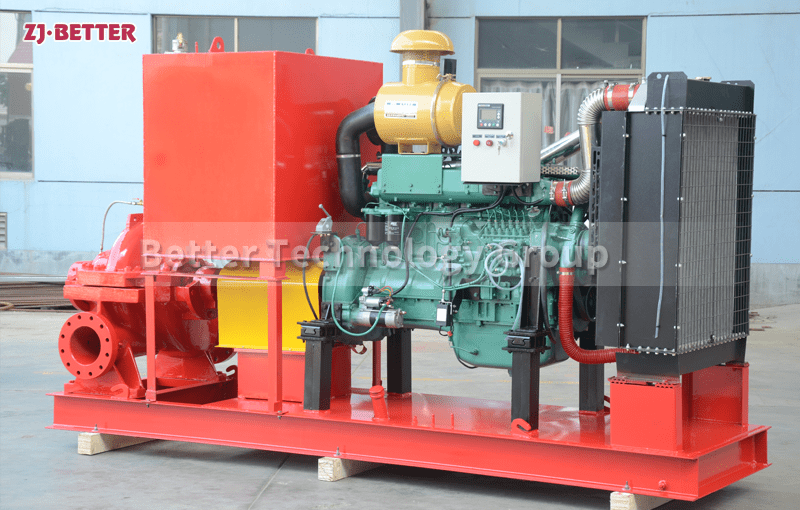

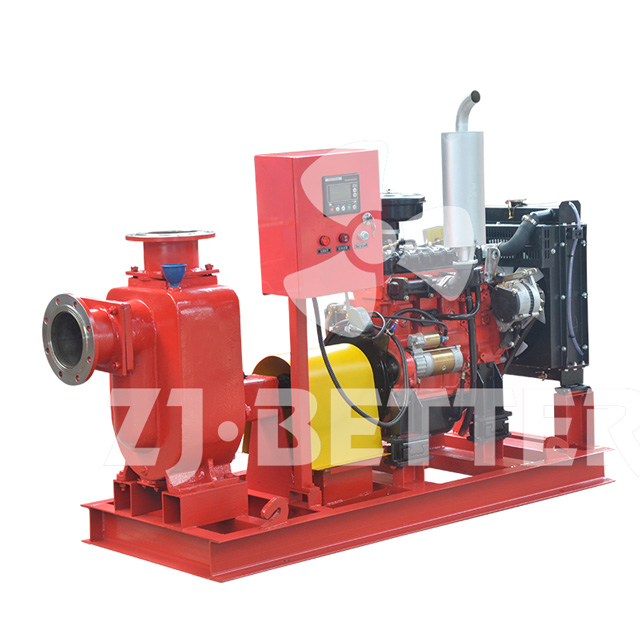

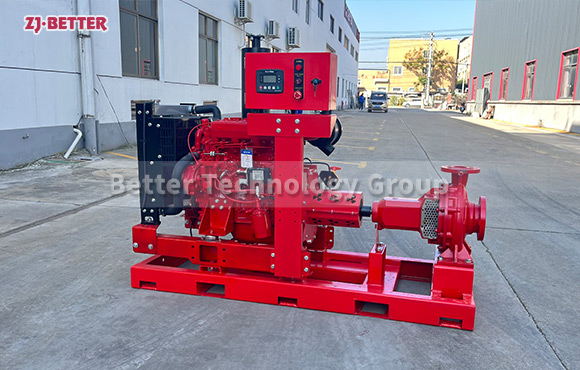

Diesel engine fire pumps are mainly used in municipal engineering for flood control and emergency rescue

Diesel engine fire pumps are mainly used in flood control and emergency municipal engineering, farmland irrigation, urban water supply and drainage, fire water supply, hydropower engineering, metallurgy, mining, petroleum, chemical and other industries, and play an important role in flood control and emergency conditions. A diesel engine fire pump is a machine that transports liquids or pressurizes liquids. It transmits the mechanical energy of the prime mover or other external energy to the liquid to increase the energy of the liquid. It is mainly used to transport liquids including water, oil, acid and alkali, emulsions, suspoemulsions and liquid metals, etc., and can also transport liquid and gas mixtures. and liquids containing suspended solids. The technical parameters to measure the performance of the pump include flow rate, suction lift, lift, shaft power, water power, efficiency, etc.; according to different working principles, it can be divided into positive displacement pumps, vane pumps and other types. Positive displacement pumps use the change in the volume of their working chambers to transfer energy; vane pumps use the interaction between rotating blades and water to transfer energy, and there are centrifugal pumps, axial flow pumps and mixed flow pumps.

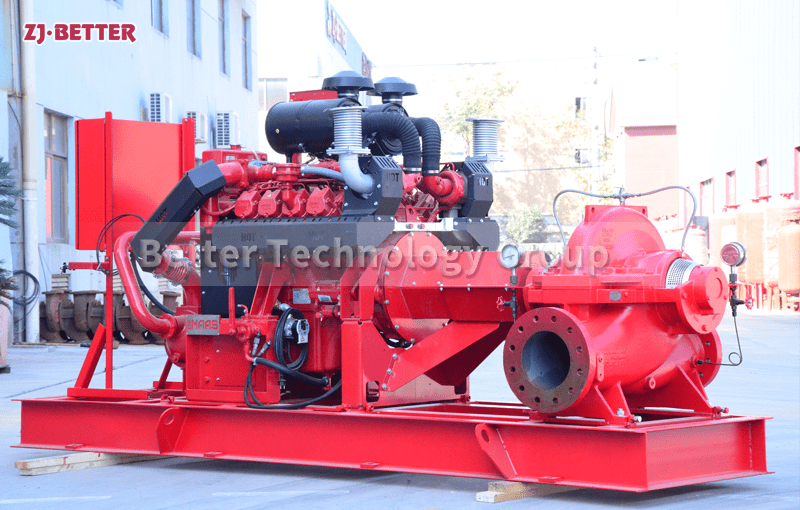

Diesel engine fire pumps are mainly used to pressurize and send water to fire system pipelines. It can also be applied to industrial and urban water supply and drainage, pressurized water delivery for high-rise buildings, long-distance water delivery, heating, bathroom, boiler cold and warm water circulation pressurized air-conditioning refrigeration system water delivery and equipment matching, etc. The pump body and pump cover of the diesel engine fire pump are split from the back of the impeller, which is the so-called rear door structure. Its advantage is that it is easy to overhaul, the pump body, the suction pipeline, the discharge pipeline and the motor are not moved during maintenance, and the rotor parts can be exited for maintenance only by removing (extending) the intermediate connecting piece of the coupling. The casing of the diesel engine fire pump constitutes the working chamber of the pump. The impeller, shaft and rolling bearing are the rotors of the pump. Suspension bearing parts The supporting parts support the rotor parts of the pump, and the rolling bearings are subjected to the radial and axial forces of the pump. In order to balance the axial force of the diesel engine fire pump, most pumps have sealing rings at the front and rear of the impeller, and a balance hole on the back cover of the impeller. Because some pumps have little axial force, there is no seal on the back of the impeller. ring and balance hole.