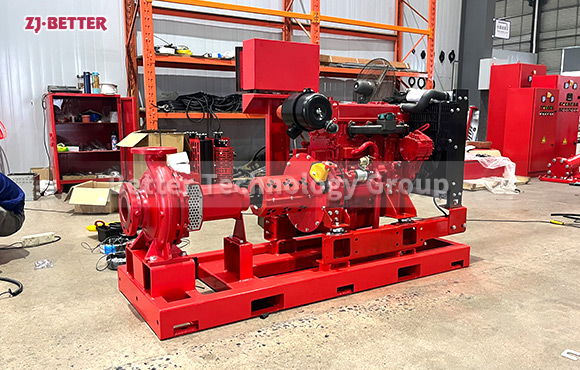

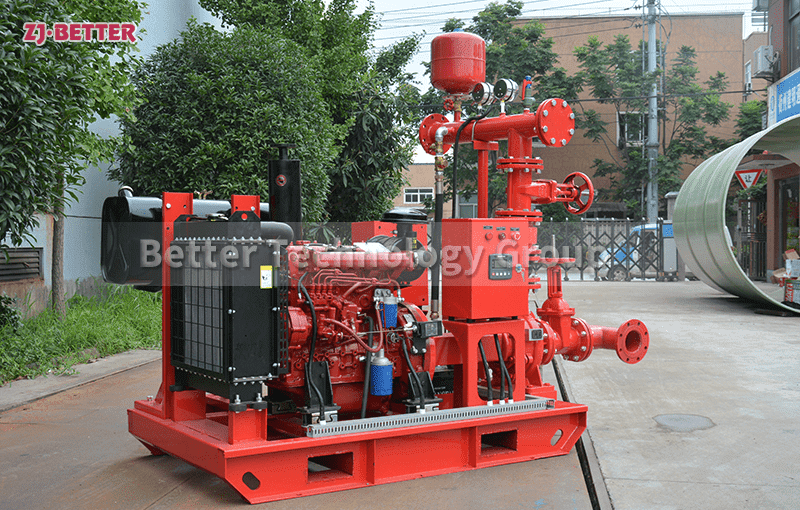

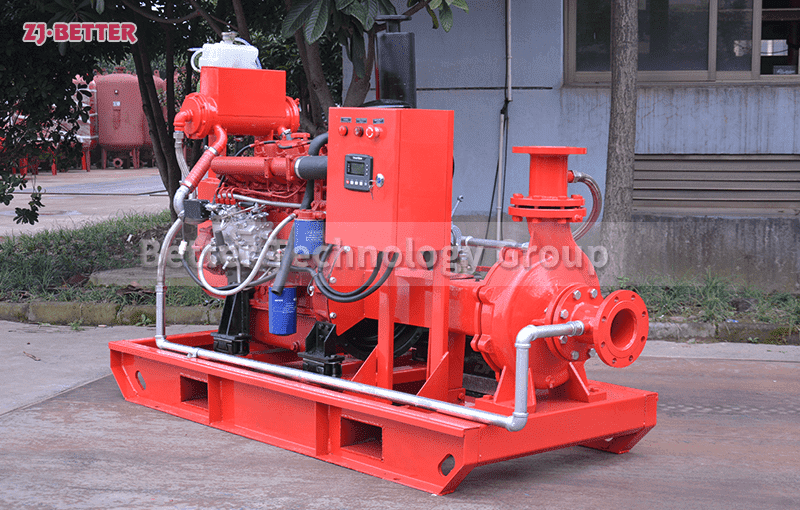

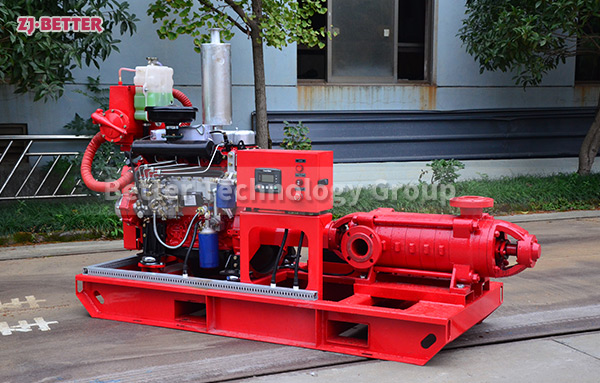

Heavy-Duty End Suction Fire Pump Set for Municipal and Commercial Applications

Explore the heavy-duty end suction fire pump set designed for municipal and commercial applications, offering reliable diesel-driven performance, robust construction, and easy installation to meet critical fire protection needs

The heavy-duty end suction fire pump set designed for municipal and commercial applications represents a powerful and reliable solution for critical fire protection systems. Built to meet stringent safety and hydraulic performance standards, this diesel-driven pump system ensures uninterrupted operation during emergencies when electrical power may not be available. Its core design utilizes a horizontal end suction centrifugal pump powered by a robust diesel engine, integrated into a complete skid-mounted unit for easy transportation and installation. One of the primary advantages of this pump set lies in its heavy-duty structure, crafted with industrial-grade materials that ensure long-lasting durability even under harsh environmental conditions. The pump casing is made of high-strength cast iron or optional stainless steel to withstand high pressure and corrosive elements, while the impeller is precision-machined and dynamically balanced for optimum hydraulic performance and reduced vibration. This ensures not only efficiency but also minimizes wear and tear, extending the life span of the pump components. The diesel engine used in this configuration is a water-cooled, four-stroke engine selected from reputable engine manufacturers, delivering high torque, fuel efficiency, and smooth startup under variable load conditions. It supports both electric start and optional automatic start features, triggered by pressure drop or external signals, ensuring a rapid response in fire emergencies. This is especially valuable in municipal and commercial environments, where timely intervention is crucial to minimize damage and ensure public safety. The pump set is equipped with an advanced control panel that monitors engine parameters such as oil pressure, water temperature, battery voltage, fuel level, and operating hours. The control system also supports remote monitoring and alarm output, making it suitable for integration into smart building management systems. This level of automation enhances operational reliability and reduces the need for manual supervision, which is particularly beneficial in large-scale commercial complexes, warehouses, airports, and municipal infrastructure facilities. Another key advantage is its modular and compact skid-mounted design. The entire system is mounted on a rigid steel base with anti-vibration pads, allowing for quick deployment without the need for complex civil works. This reduces installation time and cost, making the pump unit a preferred choice for both new projects and retrofit applications. The base frame can be customized with lifting lugs and forklift slots to facilitate easy handling during transportation and onsite positioning. For environments that require noise control, an optional soundproof enclosure or canopy can be added to reduce engine noise, enabling installation closer to populated or noise-sensitive areas. In terms of performance, the end suction pump delivers a wide range of flow rates and pressure outputs, typically from 50 to over 1000 gallons per minute, with heads ranging from 40 to 150 meters, depending on the impeller size and speed. This flexibility allows it to meet various fire protection standards such as NFPA20, UL/FM, or local fire codes. It is especially effective in systems requiring long-distance water transmission or multiple hose outlets. The pump shaft is supported by heavy-duty bearings and sealed with high-quality mechanical seals to prevent leakage, reduce maintenance frequency, and ensure reliable operation over long durations. Furthermore, the pump is designed for easy maintenance and inspection. The back pull-out design allows for disassembly of the impeller and mechanical seal without disturbing the pipe connections or motor alignment, minimizing downtime and service costs. This user-friendly maintenance feature is particularly appreciated by facility managers and service contractors. The fuel tank can be customized according to the operation duration requirement, ranging from 8-hour to 24-hour autonomous running, and includes safety features such as leak detection, level sensors, and emergency shutdown. This ensures that the diesel engine continues to run reliably during extended fire-fighting operations, even in remote or power-isolated areas. The versatility of this fire pump set makes it suitable for various commercial and municipal applications, including government buildings, water treatment plants, shopping malls, high-rise buildings, oil depots, ports, logistics centers, and stadiums. Its adaptability to different environmental conditions—whether indoor, outdoor, tropical, or desert climates—further enhances its appeal to international markets. Moreover, the product can be supplied with full documentation, including installation manuals, test certificates, material traceability reports, and compliance declarations, ensuring smooth project approval by consultants and regulatory authorities. This heavy-duty end suction fire pump set can also be paired with electric jockey pumps or backup electric fire pumps to create a complete fire pump package that guarantees redundancy and performance. Overall, its key advantages include robust construction, reliable diesel drive, smart control features, easy installation, low maintenance, high hydraulic performance, compliance with international standards, and wide adaptability across application scenarios. These benefits collectively ensure that the product not only meets but exceeds the expectations of engineers, facility managers, and fire protection consultants involved in municipal and commercial fire safety projects.

.jpg)