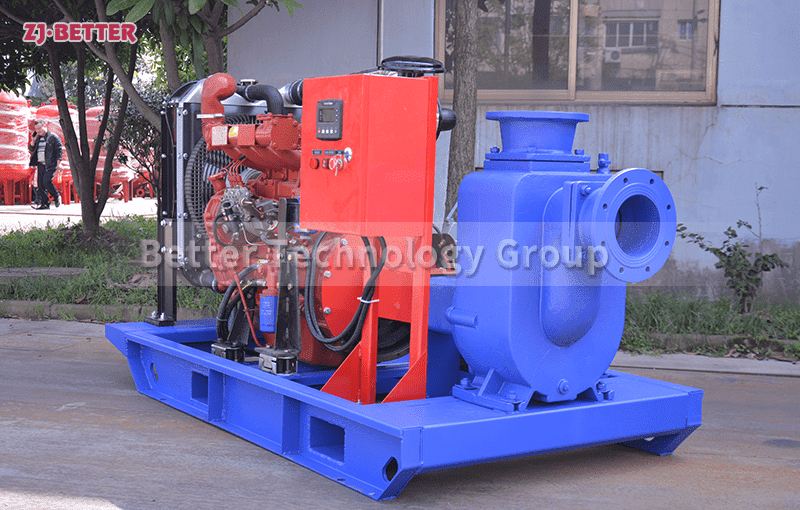

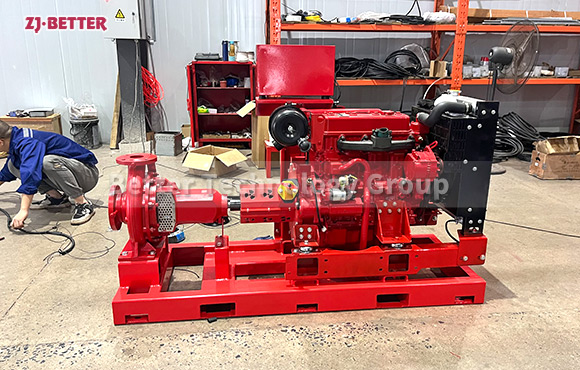

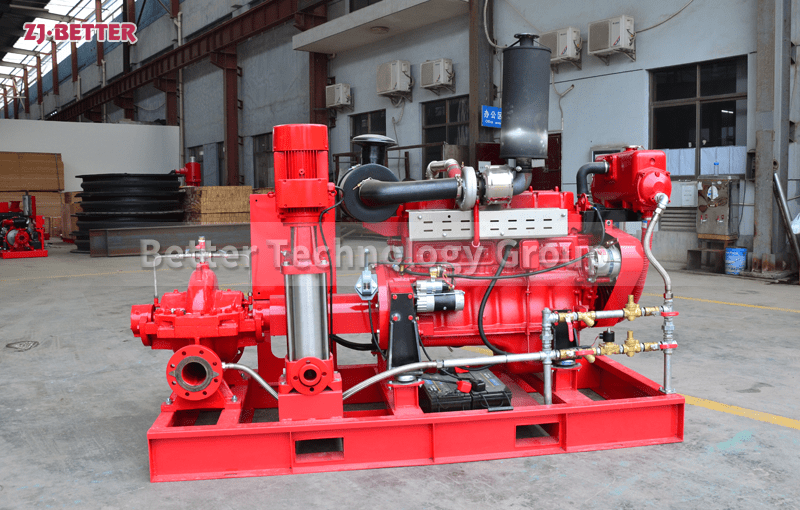

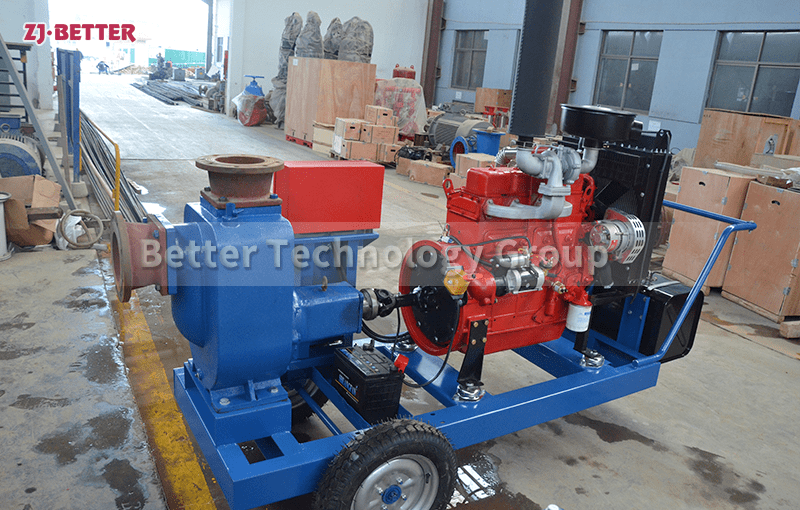

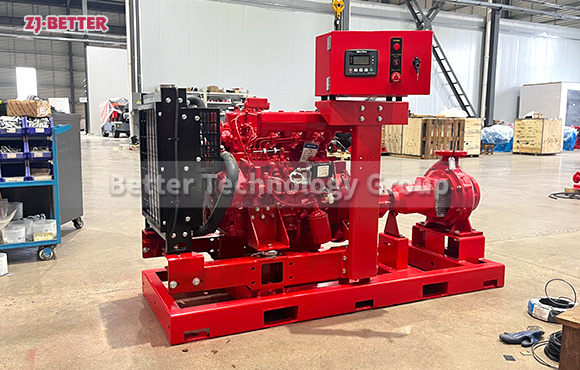

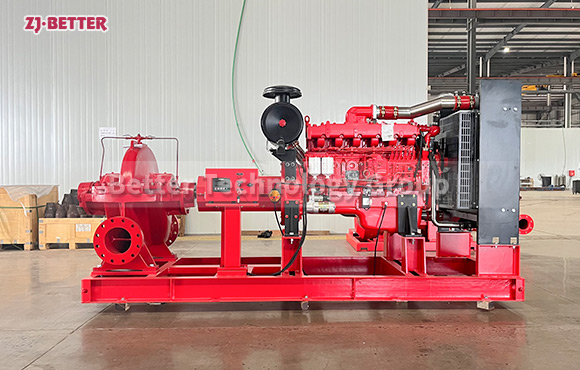

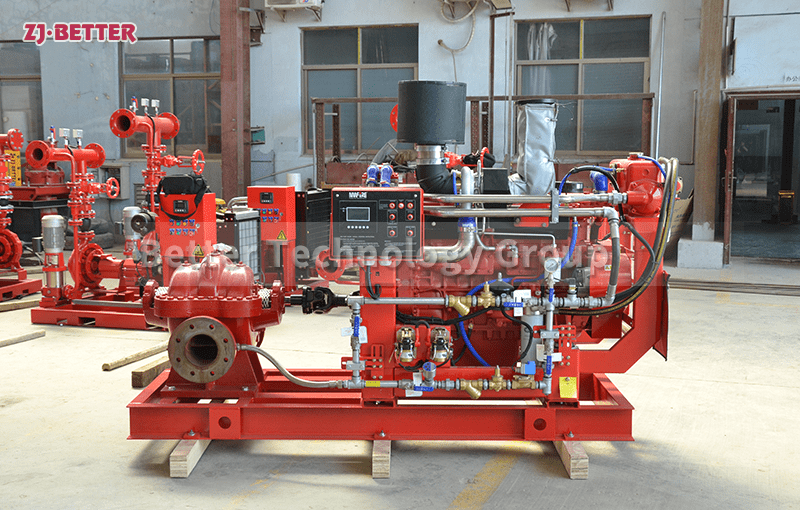

Large Flow Diesel Fire Pump

The diesel engine fire pump has automatic, manual and fault self-checking functions. It can monitor the working state of the whole process, restore the function of failure start, automatic pre-lubrication and automatic restart of preheating, so that the equipment start-up is safer and more reliable. It has the functions of central control room remote control, remote control and field bus connection. The battery is fully automatic floating charge (constant current, constant voltage, trickle charge) mode to ensure that the battery is in a standby state at any time. Diesel engine fire pump is easy to use, equipped with remote instrument and instrument, which can be connected to the control center as needed, easy to install and use, and easy to maintain.??

After receiving the fire/pipe network pressure/power failure/other start signals, the diesel engine fire pump can automatically start and enter full load operation within 5 seconds. The battery can be automatically charged by the main power supply or the diesel charging motor to ensure the smooth start of the equipment; automatic alarm protection for low oil pressure, high water temperature and other faults of the diesel engine, overspeed alarm and shutdown; the diesel engine fire pump is in a hot engine standby state to ensure emergency work. The diesel engine fire pump adopts the direct connection technology between the diesel engine and the water pump. Through the elastic coupling, the failure points are reduced, the start-up time of the unit is greatly shortened, and the reliability and emergency performance of the unit are improved.