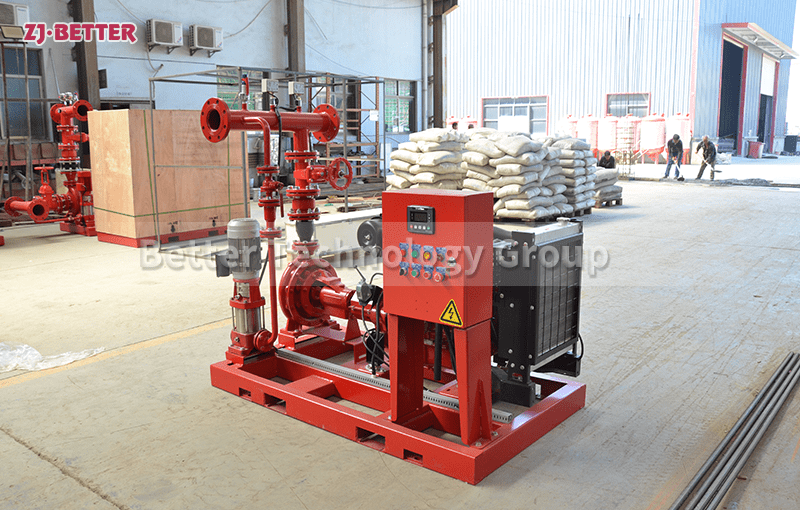

Features of Self-priming Fire Pumps Manufactured By Better

The self-priming pump is a kind of water pump. The difference from other pumps is that it can separate water and gas by itself, form a negative pressure inside, and fill the diversion water. Before the new pump is used, a little water should be poured into the pump body, which is conducive to the rapid separation of steam and water. In addition, the installation position should be careful not to exceed its suction stroke.

Self-priming fire pump is a research and development equipment according to the provisions of my country’s fire regulations and the different requirements of various users. The product is innovative, advanced and practical. It simplifies the design of the pump room. The underground pump room can be changed to the ground, which is convenient for construction and saves investment; the outdoor pool can also be used to meet the requirements of use; the self-priming function can be used to make the fire pool deeper. To 3-6m, under the same effective volume, the land area occupied by the pool is much smaller than the original, which saves land, facilitates construction, reduces construction costs, and greatly saves investment; it can work under the condition of negative water level and meet the requirements in time. Fire protection requirements; the self-priming fire pump can discharge water in time to rescue and extinguish fires in time; it has a strict and reliable automatic circuit detection function, so that the unit is usually in a quasi-fire-fighting state.