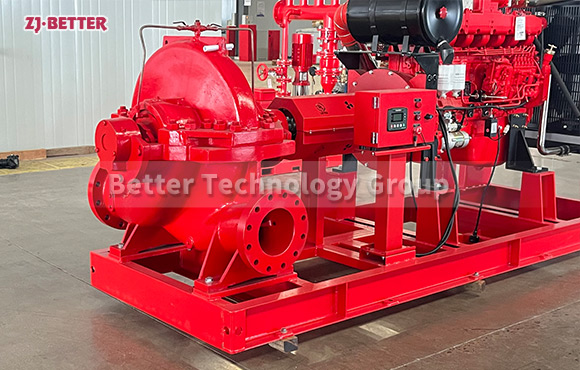

Diesel engine fire pump is a common fire extinguishing equipment

Diesel engine fire pump is a common fire fighting equipment, especially suitable for use in places without electricity supply. The diesel engine fire pump uses a diesel engine as a power source to convert the work of the pump into hydraulic power to achieve a certain flow and pressure. It is mainly used in building fire protection, engineering fire protection, water source fire extinguishing and other fields.

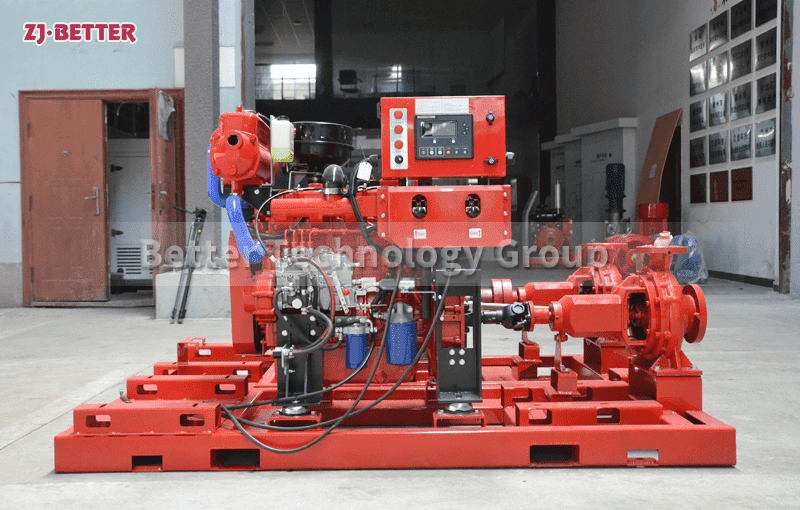

The diesel engine fire pump has a high degree of automation, with automatic, manual and fault self-inspection functions, and monitors the working status during the whole process. It can restore the automatic restart function after failure, automatic pre-lubrication and pre-heating, so that the equipment can start more safely and reliably. The diesel engine fire pump has remote control and remote control functions in the central control room. It can also have a fieldbus connection. The battery adopts fully automatic floating charge (constant current, constant voltage, dripping charge) to ensure that the battery is in a standby state at any time.