The advantage of the diesel engine fire pump is that it has a wide range of applications

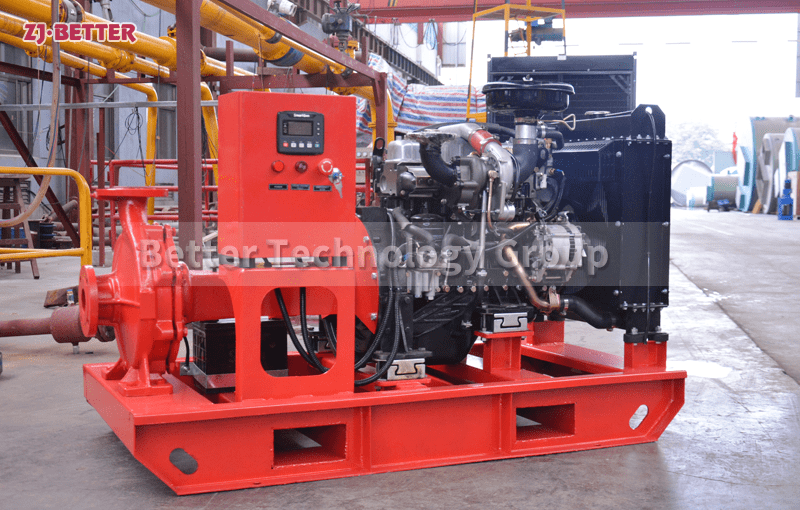

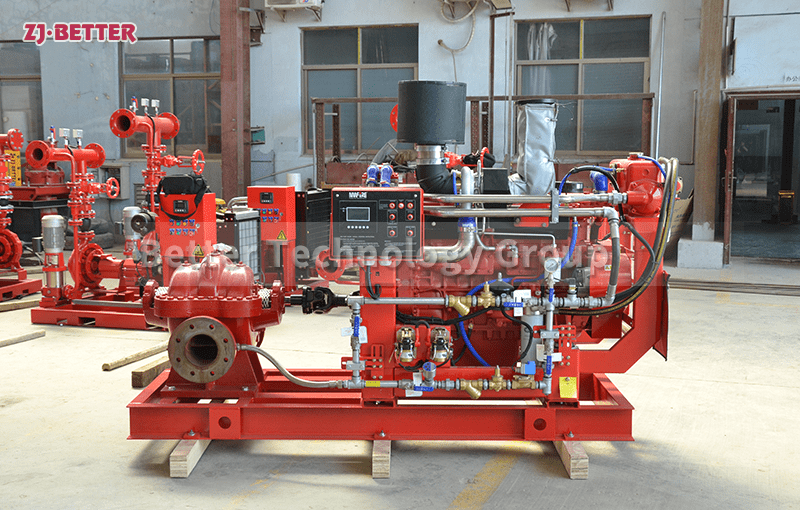

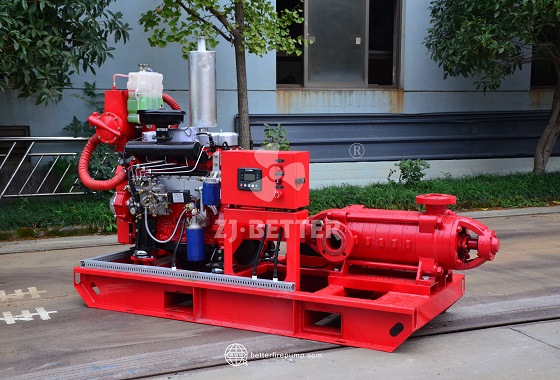

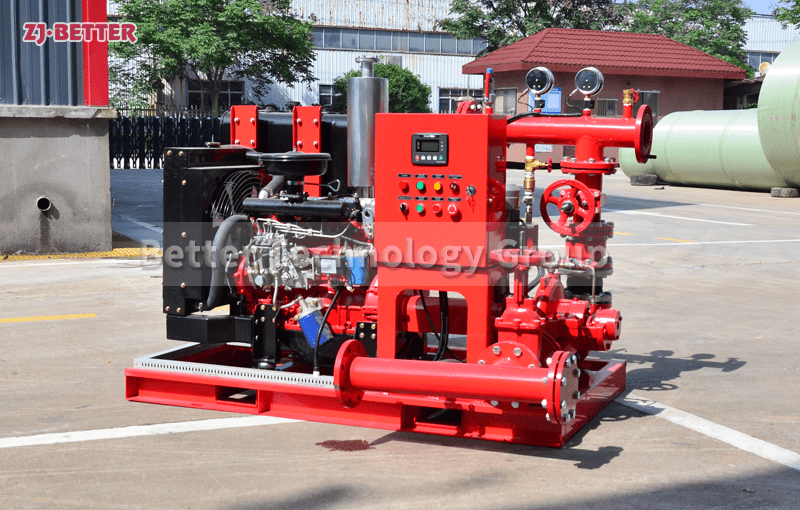

The fire pumps used in the complete set of diesel engine fire pumps can be the IS series single-stage type, the S series new single-stage two-stage type, and the D-type series segmental multi-stage type produced by our company. The diesel engine fire pumps used in this series of equipment are made of domestic or imported high-quality products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use, and high degree of automation. They are advanced and reliable fire-fighting equipment.

The advantages of diesel engine fire pumps are wide application range, convenient use and high efficiency. It can start quickly and provide emergency fire protection in the external environment without electricity. The diesel engine fire pump can ensure that the water pump will not overheat during long-term operation through the diesel engine cooling system. Moreover, this type of fire pump can better store water resources and avoid disasters caused by insufficient water sources during fire fighting. In addition, the construction of diesel engine fire pump is simpler than traditional fire fighting equipment, and it is easier to maintain and maintain.