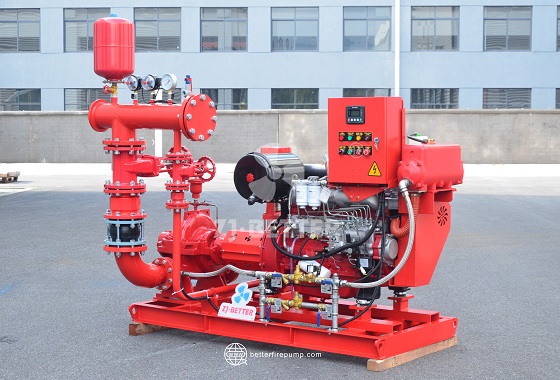

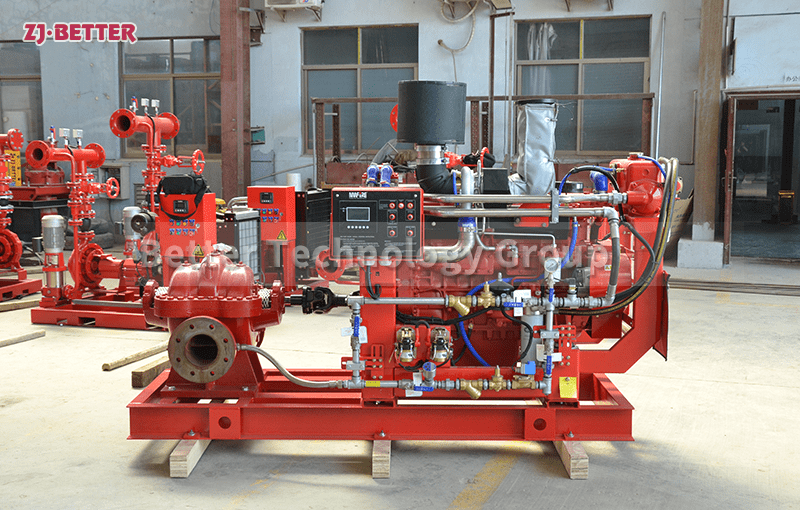

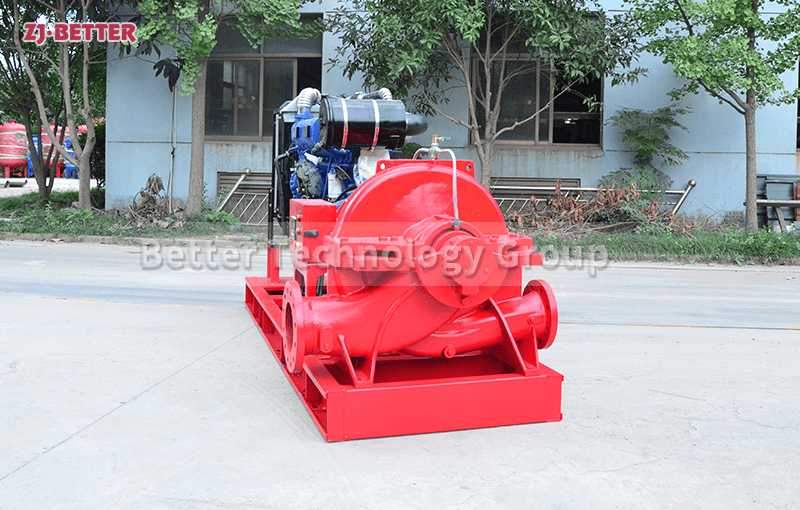

Performance characteristics of diesel engine fire pump

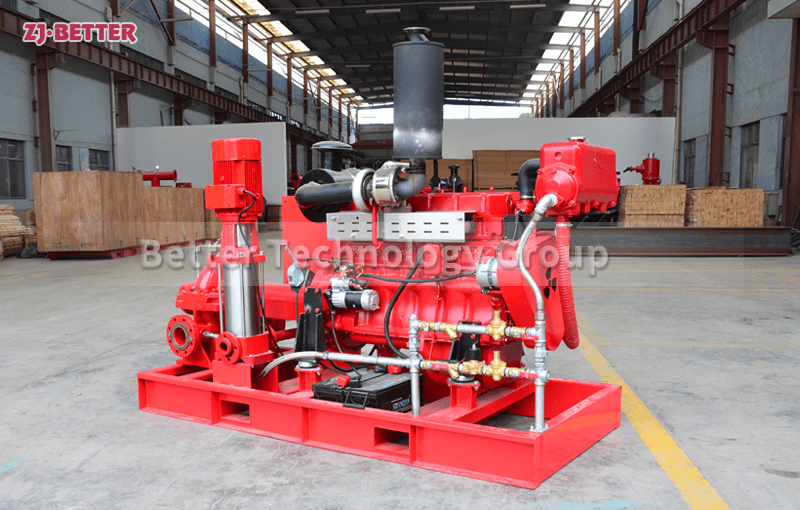

When the diesel engine fire pump unit receives an effective fire signal, if the power supply system of the diesel engine fire pump is powered off, loses phase or the electric pump cannot start normally, the diesel engine fire pump unit will automatically start to run. Once the power supply system returns to normal or the electric pump can operate normally, it can automatically switch to the electric pump.

Diesel engine fire pumps have three starting functions:

1. Manual start function: Manual and automatic interlocking can be completed through the transfer switch, and manual start function can be realized:

2. Automatic and manual function: three starts are allowed. If it fails to start three times, it will issue a “start failure alarm” and automatically exit the start state. After a successful start, the time from start to rated load is 5-10-15S (depending on the capacity of the unit);

3. Emergency manual direct start function: When the automatic control device fails, the emergency manual direct start function can be realized.