Diesel engine multistage fire pump set has a wide range of performance

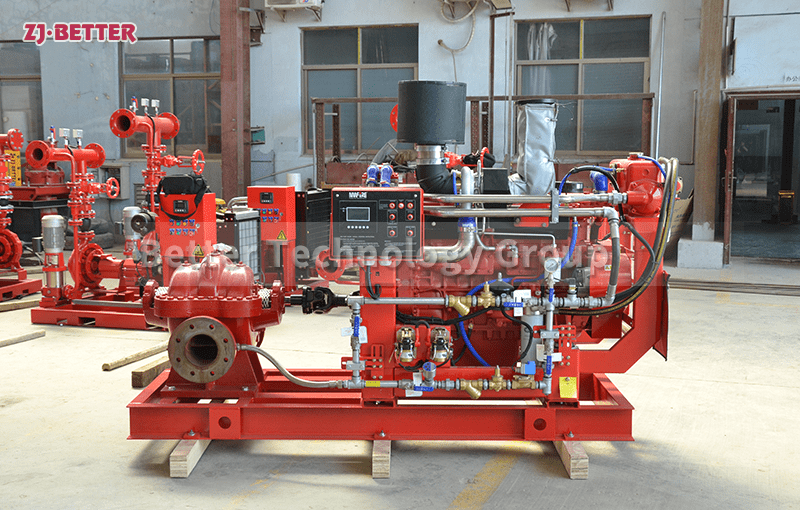

Diesel engine multi-stage fire pump set is in accordance with the national standard GB6245-2006 “Fire Pump Performance Requirements and Test Methods”. This series of products has a wide range of head and flow rate, which can meet the fire water supply in various occasions of industrial and mining enterprises such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, and textiles. The advantage is that the electric fire pump cannot be started after the power system of the building suddenly loses power, and the diesel engine fire pump is automatically started and put into emergency water supply.

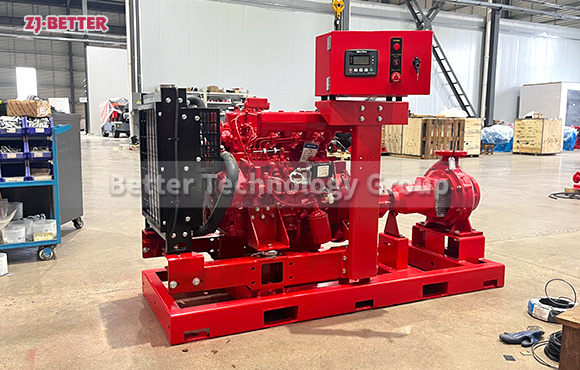

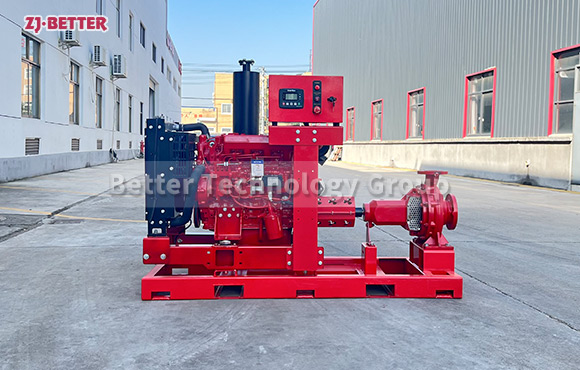

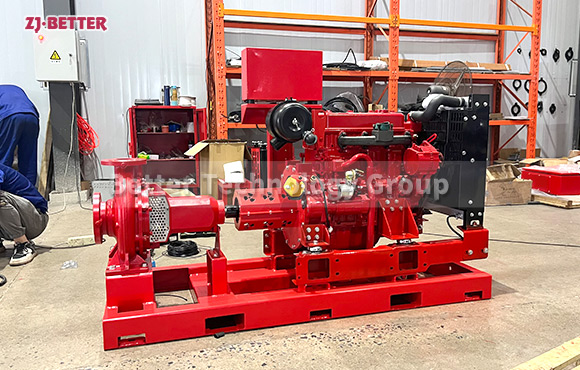

The diesel engine multi-stage fire pump is composed of a diesel engine and a fire pump. The pump unit is a horizontal, single-suction, multi-stage centrifugal fire pump. It has the characteristics of high efficiency, wide range of performance, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. It is used to transport clear water or other liquids whose physical and chemical properties are similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump’s flow parts, sealing form and adding a cooling system.