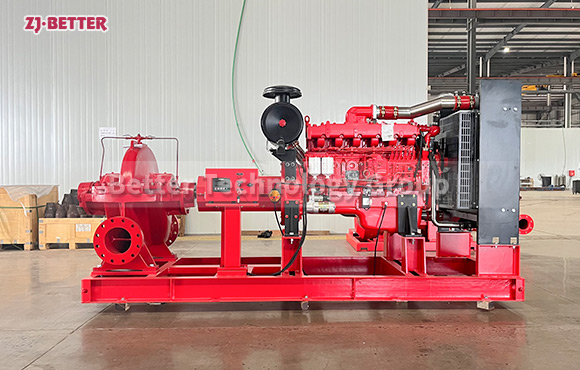

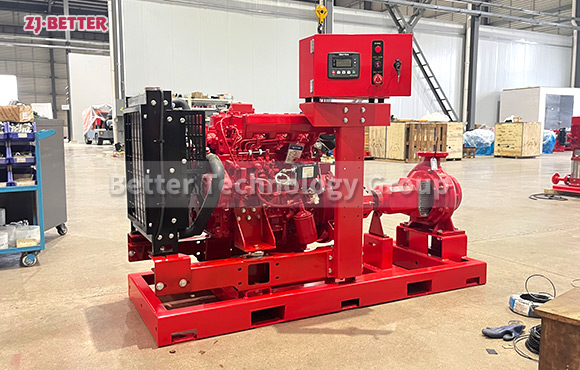

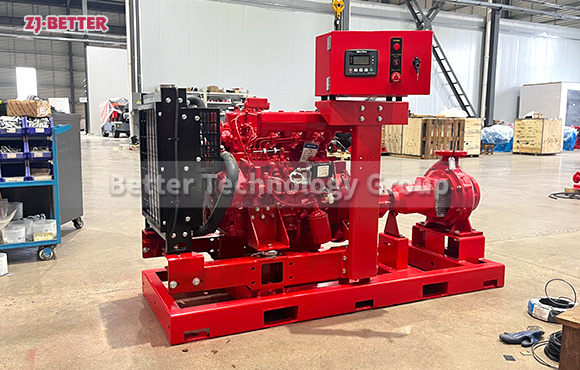

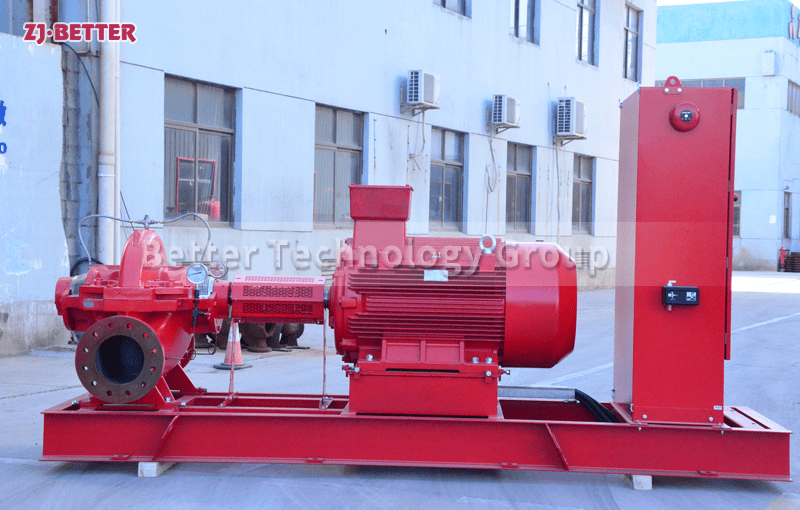

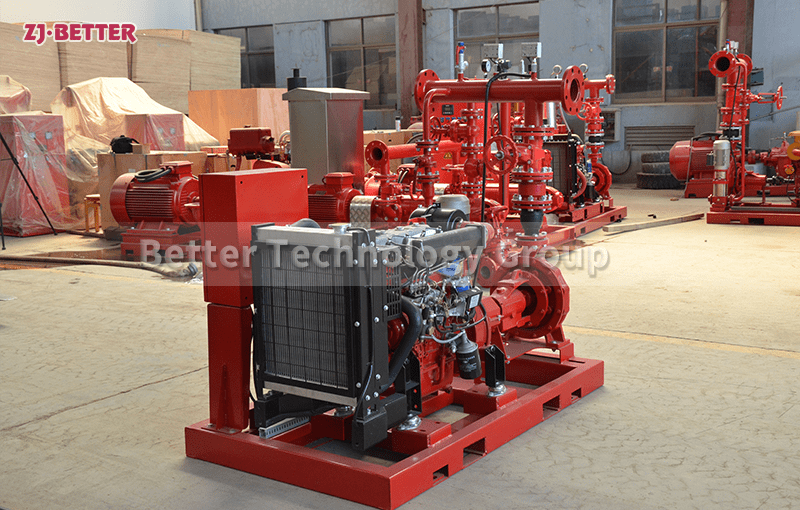

OTS Large Diesel Fire Pump Pump

OTS fire pump is a kind of general-purpose mechanical equipment with a large number and a wide range of high lift. It is widely used in petroleum, chemical industry, electric power metallurgy, mining, ship selection, light industry, agriculture, civil use and various departments. It is widely used in the national economy. occupy an important position.

The split pump is also known as a single-stage double-suction centrifugal pump, and its main features are the large flow rate and high lift of the conveying medium. The working principle of the split pump operation: The impeller is installed in the pump casing and fastened to the pump shaft, which is directly driven by the motor. There is a liquid suction and suction pipe in the center of the pump casing. The liquid enters the pump through the bottom valve and suction pipe. The liquid discharge port on the pump casing is connected with the discharge pipe. When the speed of the pump is constant, its pressure head and flow rate are related to the diameter of the impeller.