How does the dual power system switching ensure continuous operation?

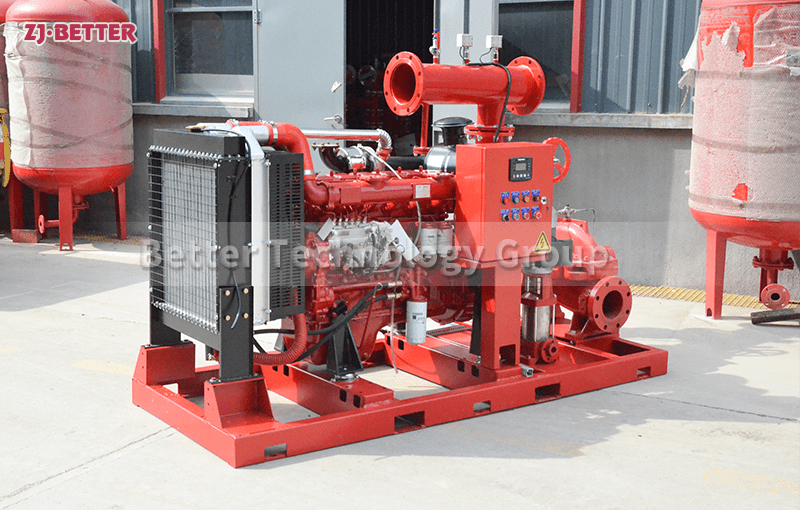

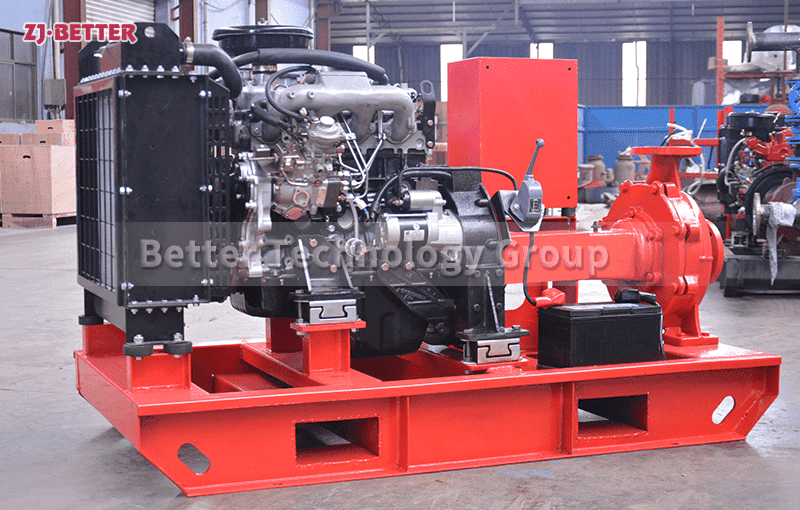

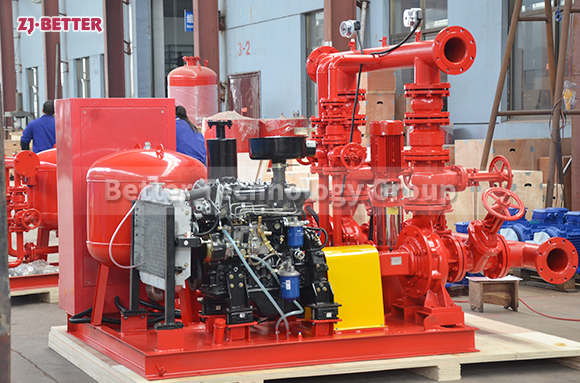

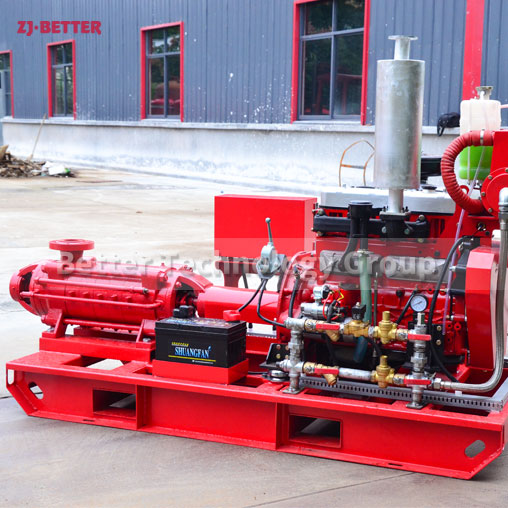

This fire pump features an advanced dual-power system, supporting both electric and diesel modes to ensure uninterrupted operation even during power outages. The high-efficiency pump body delivers a stable and powerful water flow, meeting emergency rescue demands. Its automatic control system enables remote monitoring and intelligent alarm functions, providing real-time equipment status feedback for enhanced safety. With a compact structure and small footprint, it is easy to install and maintain, making it suitable for various complex environments. Additionally, the pump is built with corrosion-resistant materials, ensuring long-term stability and reduced maintenance costs, offering users a highly reliable fire protection solution.

Our company specializes in the research and production of high-performance fire pumps, dedicated to providing efficient, safe, and reliable fire protection solutions for customers worldwide. Our product range includes electric fire pumps, diesel engine fire pumps, and pressure-stabilizing water supply equipment, widely used in industrial, commercial, and residential buildings. All products feature advanced hydraulic designs to ensure high head and large flow output, meeting the fire safety needs of various scenarios. The integration of an intelligent control system enables automatic start-stop, remote monitoring, and fault warnings, significantly enhancing operational safety and convenience. With a compact structure and small footprint, our equipment is easy to install and maintain, while corrosion-resistant materials ensure long-term stability and lower maintenance costs. With outstanding performance and strict quality management, our fire protection solutions are highly recognized in the market, providing comprehensive fire safety assurance to our customers.