Reliable Diesel Fire Pumps: Essential for Commercial Fire Safety

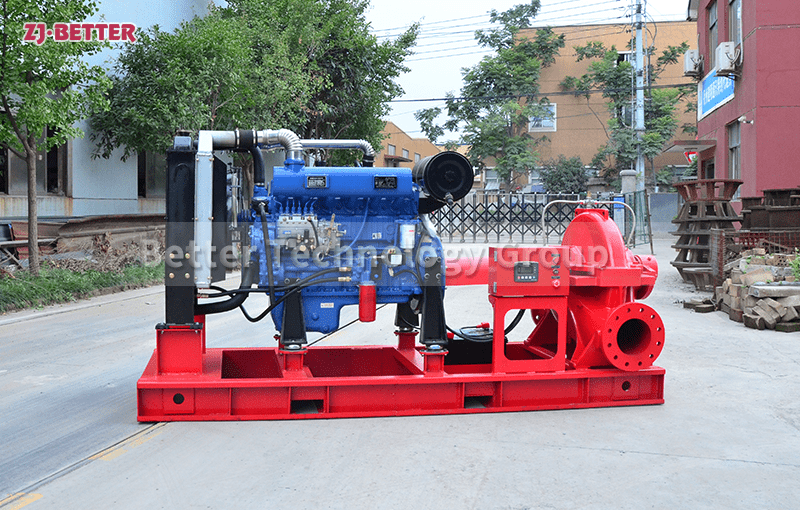

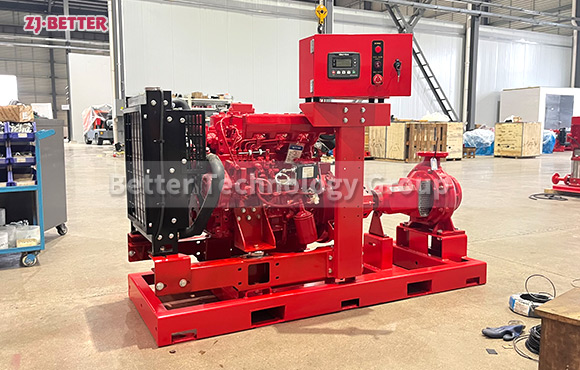

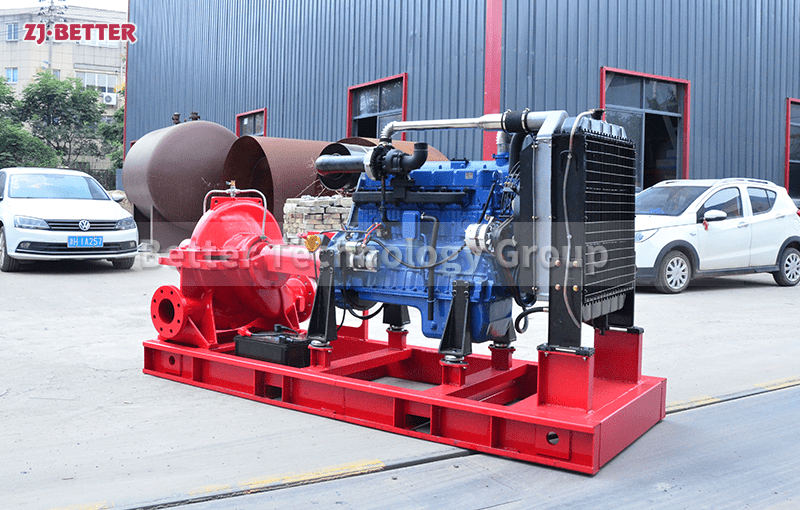

Flow:50-5000 GPM

Head:3-16 Bar / 40-232 psi

Power:11-1000 kw

Frequency:50 or 60 Hz

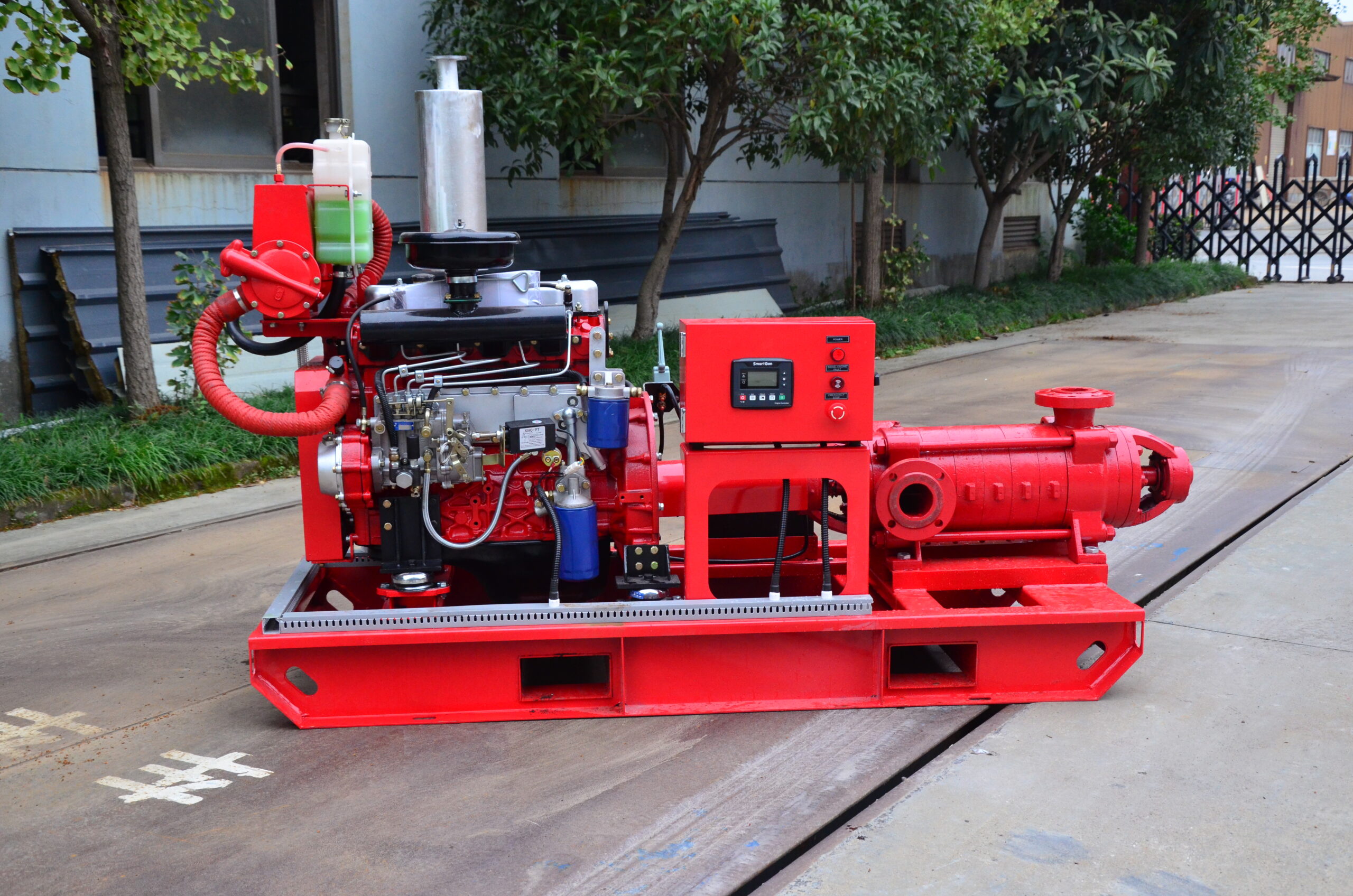

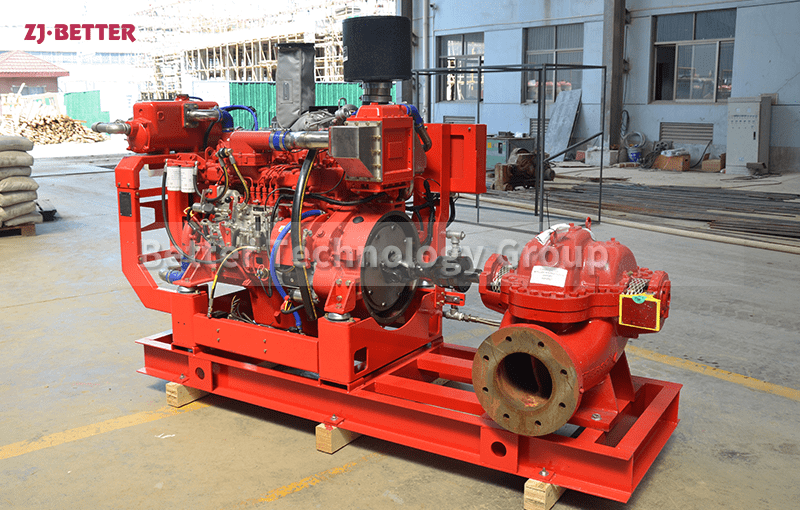

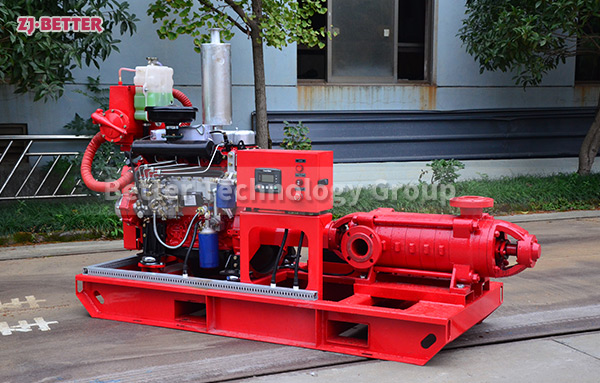

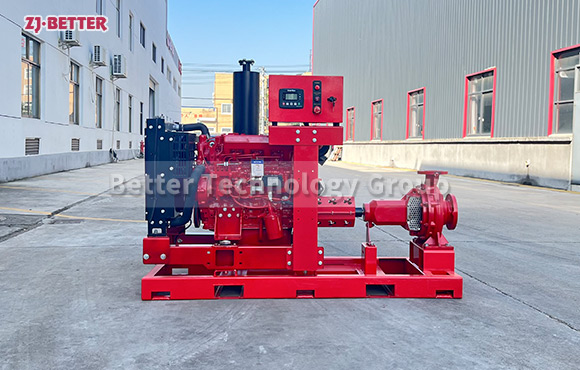

The Diesel Single Stage Centrifugal Pump is suitable for firewater supply and emergency water supply in various environments such as warehouses, docks, airports, petroleum facilities, chemical plants, power plants, liquefied gas facilities, textile mills, ships, and oil tankers

The Diesel Single stage centrifugal pump features the following product characteristics:

1.Powerful pumping capacity: Equipped with a robust diesel engine, the Diesel Single stage centrifugal pump delivers exceptional pumping capacity, enabling the swift and efficient transfer of large volumes of fluid.

2.Reliable performance: The Diesel Single stage centrifugal pump is renowned for its reliable performance, ensuring stable and enduring operation to meet various fluid transfer requirements.

3.Versatile applications: The Diesel Single stage centrifugal pump finds wide-ranging applications across industries, including industrial, agricultural, and construction sectors, catering to diverse fluid transfer needs.

In summary, the Diesel Single stage centrifugal pump offers efficient and reliable fluid transfer solutions with its unique end suction design, powerful pumping capacity, reliable performance, and advanced automatic control system. Whether for industrial fluid transfer or other fluid requirements, the Diesel Single stage centrifugal pump meets your needs!