Home » Diesel engine fire pump » 330kw Diesel engine split case fire pump

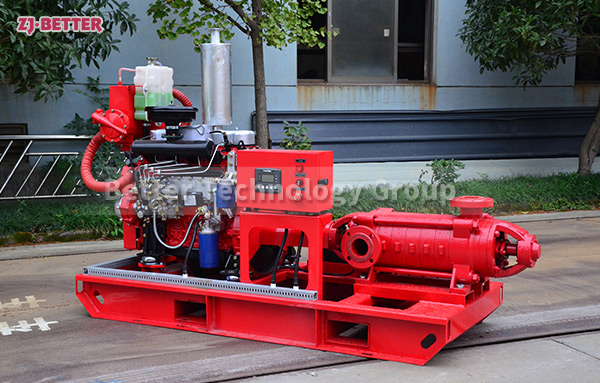

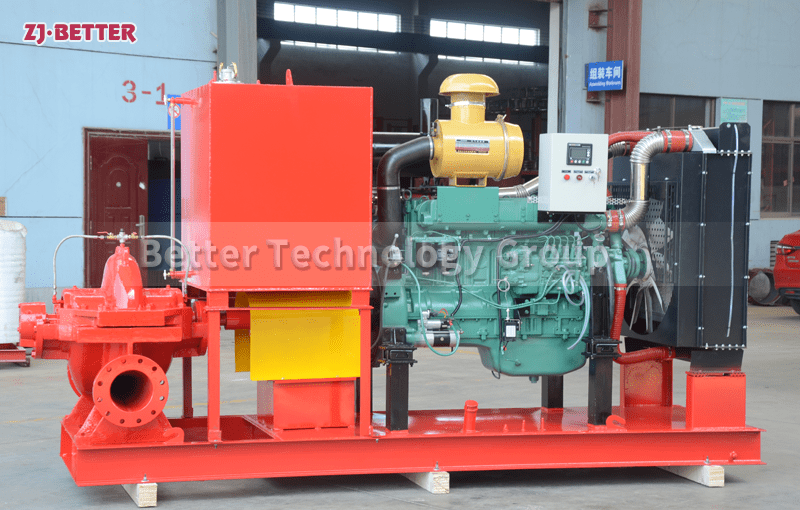

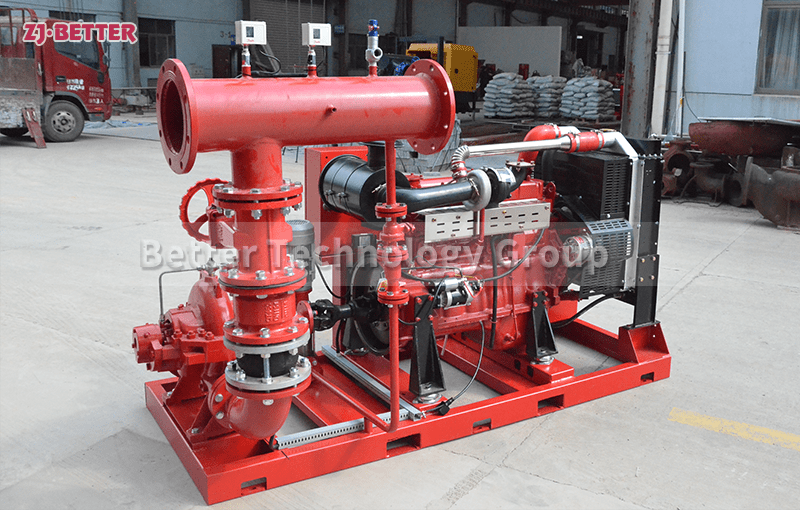

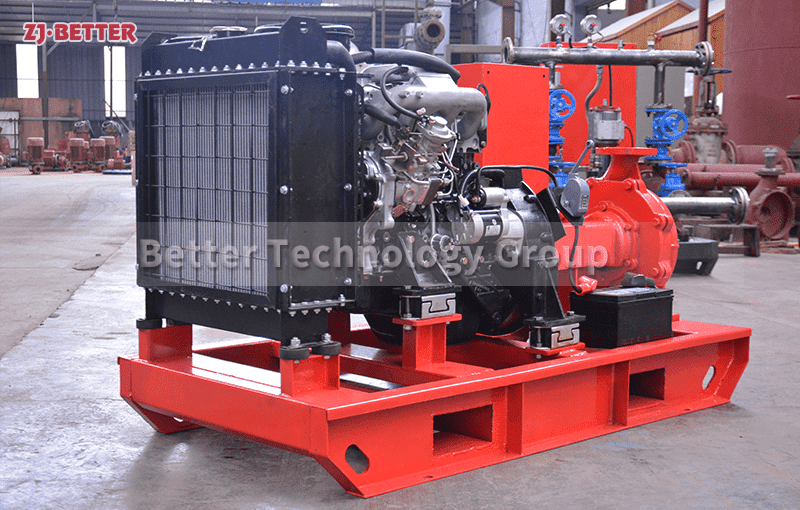

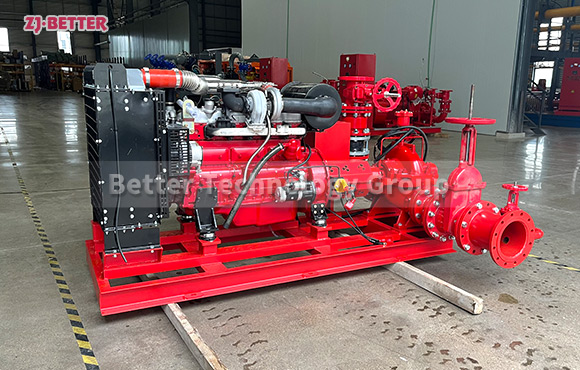

330kw Diesel engine split case fire pump

Environmental and Working Conditions

Ambient temperature:

Ambient temperature range 4℃-40℃.

Working to improve the ambient temperature every 5℃, its power decreased by 1%(to 25℃ as the base);

Altitude:

Reference elevation 91.4m, the reference atmospheric pressure is 100KPa;

If the work to an altitude of over 1000m, reference should be corrected GB1105 1-1987 diesel engine power, you can consult the specific technical department;

Relative humidity ≤80% (20℃), outdoor allow 90% (when installed outdoors in the order presented, you can choose to configure the outdoor structure, protection class IP55).

Contact US

Get Price

Share:

Content

Application

Chemical, oil refining, metallurgy, energy, medicine and military and other enterprises;

Processing or storage of petroleum or similar products;

Docks, transport ships, etc.

Large hotels, hospitals, gymnasium and other large public places;

Large shopping malls, large complex;

Processing or storage of petroleum or similar products;

Docks, transport ships, etc.

Large hotels, hospitals, gymnasium and other large public places;

Large shopping malls, large complex;

Inquiry

More Diesel engine fire pump