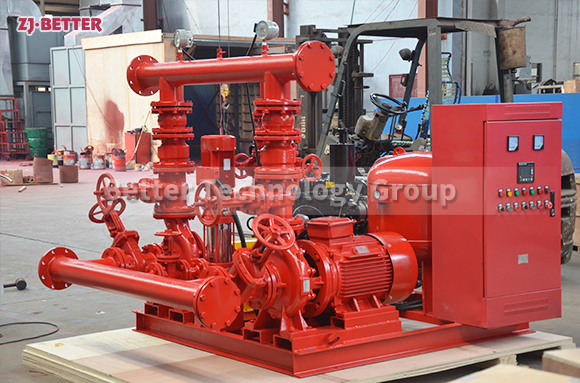

Discover the Power and Reliability of XBC 6/35-IS Diesel Engine Fire Pump for Superior Fire Protection!

The XBC-IS Diesel Fire Pump Set is a versatile solution suitable for a wide range of applications. From hotels, hospitals, and sports arenas to chemical plants, refineries, metallurgical facilities, energy plants, and pharmaceutical companies, this pump set ensures reliable fire protection. It is also ideal for shopping malls, commercial complexes, office buildings, and high-end residential towers. Whatever the setting, the XBC-IS Diesel Fire Pump Set delivers dependable performance to safeguard lives and properties from fire risks.

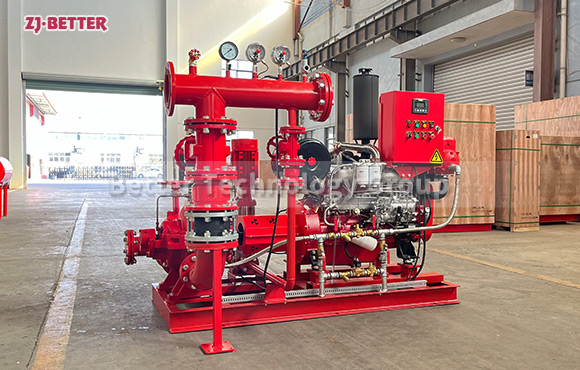

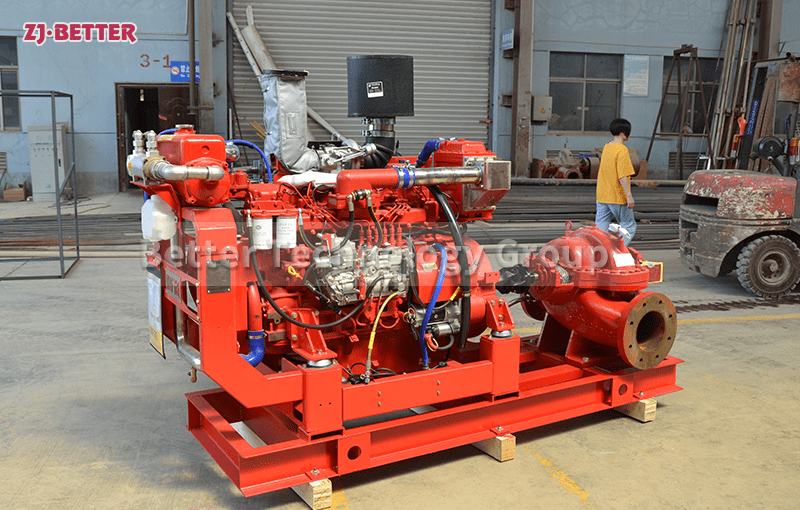

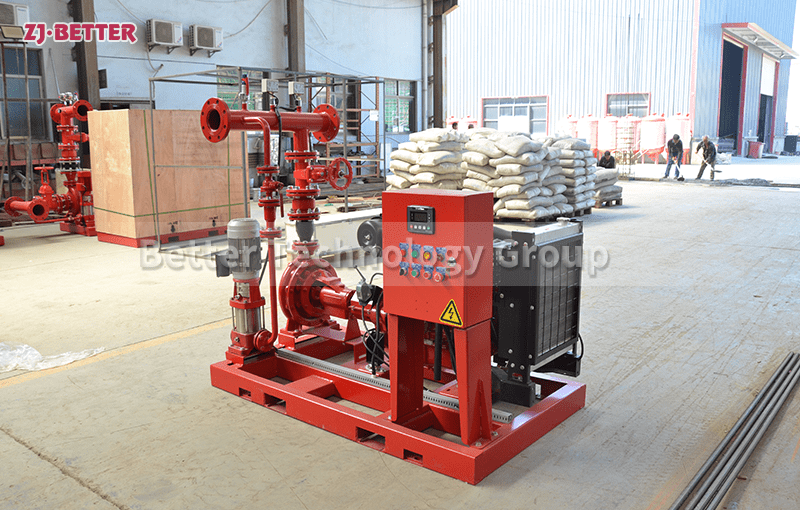

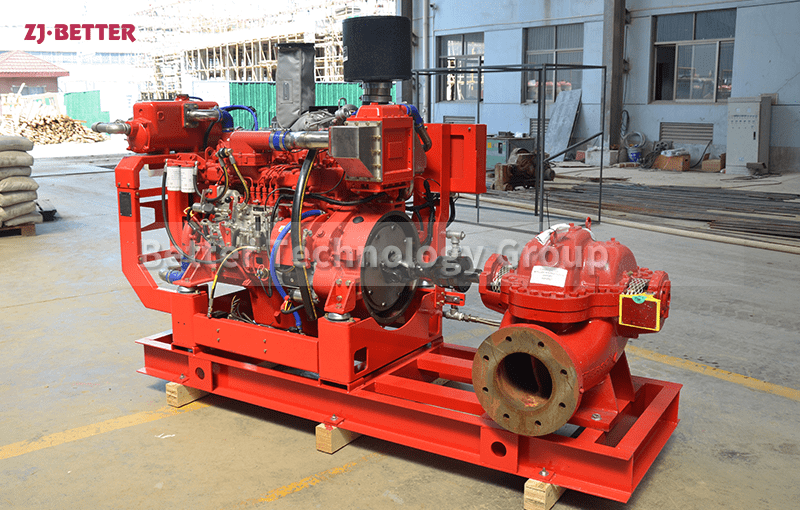

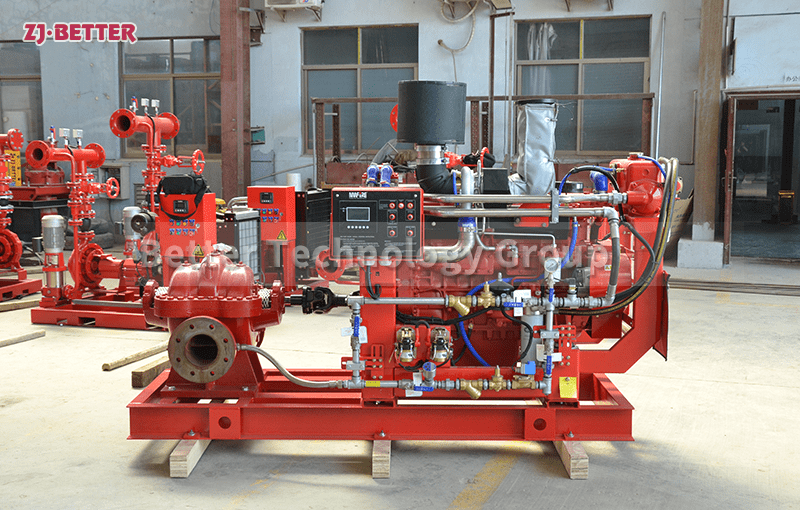

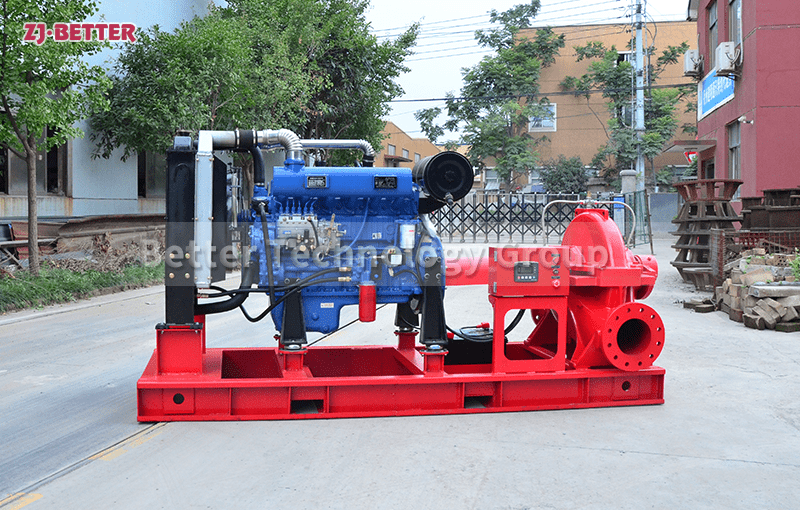

🌟 Superior Performance: Equipped with a high-performance diesel engine, the XBC-IS Fire Pump delivers robust power and outstanding firefighting capabilities. It provides a consistent water supply with ample pressure and flow rate, ensuring effective fire suppression in critical situations.

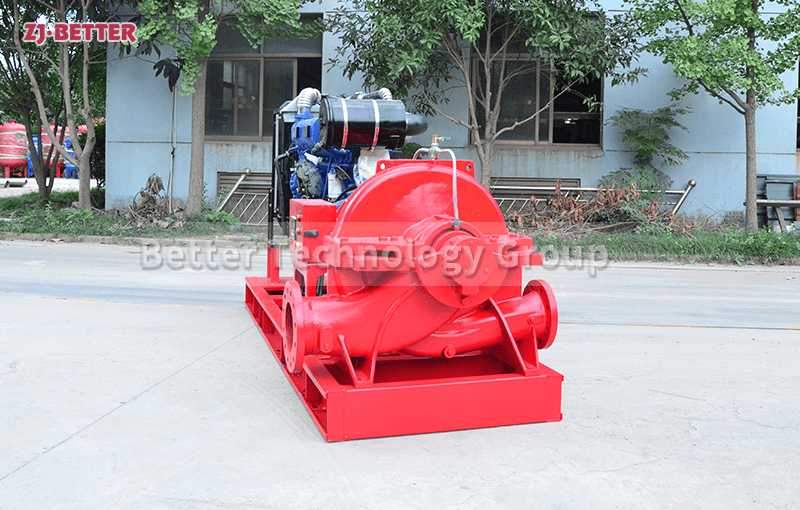

💪 Built to Last: Crafted with durability in mind, the XBC-IS Fire Pump is constructed using top-quality materials and precision engineering. It’s built to withstand harsh conditions, ensuring long-term reliability and peace of mind when it matters most.

🔒 Automatic Operation: The XBC-IS Fire Pump features an advanced automatic control system, enabling easy startup, shutdown, and monitoring. With its intelligent functionality, it ensures seamless operation and real-time status updates, simplifying firefighting operations.

🏢 Versatile Applications: From industrial facilities and commercial buildings to residential complexes and public infrastructure, the XBC-IS Fire Pump is designed to handle diverse firefighting scenarios. It’s your go-to solution for safeguarding lives and property in any environment.

💡 Expert Support: Backed by a team of knowledgeable professionals, we provide comprehensive support and expertise to ensure you make the most of your XBC-IS Fire Pump. Our commitment to customer satisfaction means you’re never alone in your fire protection journey.