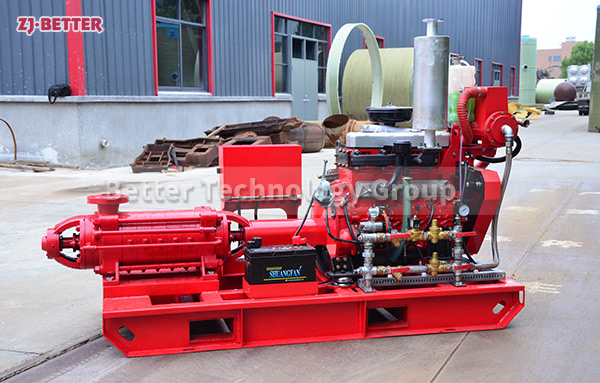

Learn about the advantages of diesel fire pumps

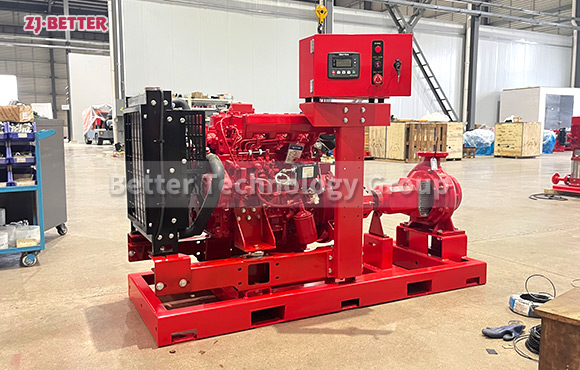

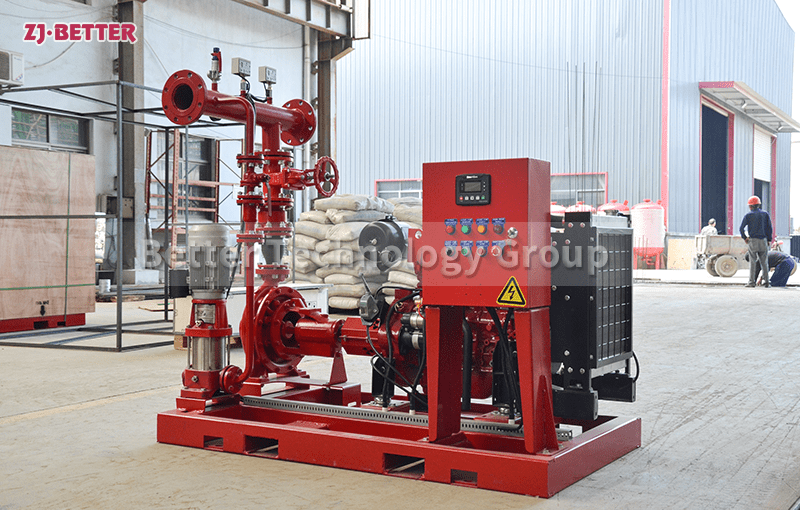

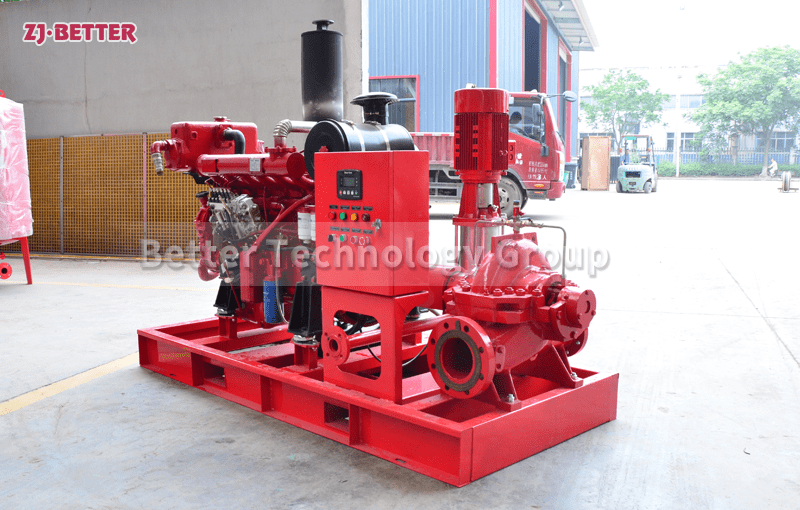

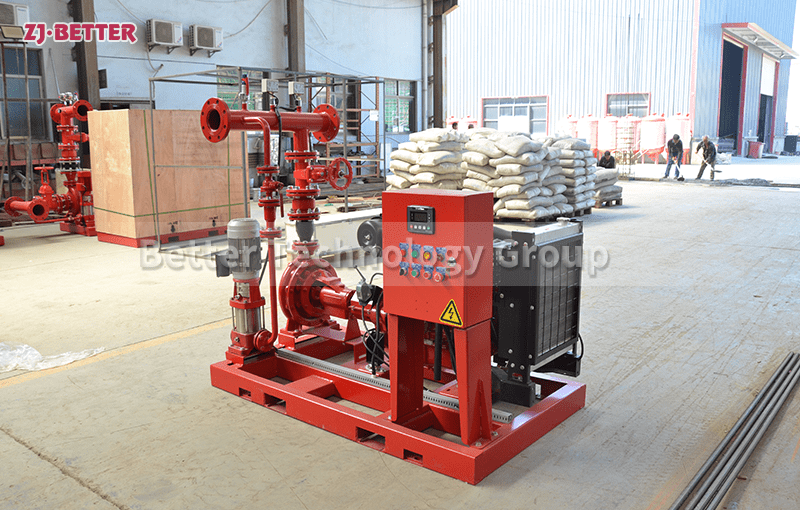

The diesel engine fire pump is installed together with the electrical instrument, with complete functions, compact structure, automatic fault alarm, accepting the starting signal, and can automatically complete the starting procedure and run at full load quickly. When the diesel engine fire pump is insufficient in fuel, low battery voltage, and high lubricating oil temperature , enough to ensure that the diesel engine fire pump starts in a low temperature environment, the entire system of the diesel engine fire pump is safe, reliable, and easy to use. Diesel engine fire pumps can be widely used in environmental protection, water treatment and fire protection departments to transport various liquids by using their own advantages.

Advantages of Diesel Engine Fire Pumps

1. The function of the diesel fire pump is very powerful. We can set the control time during use, such as: preheating, pre-lubricating or timing start. The use of high-tech has made some complicated and time-consuming things easier in the past. The preheating setting greatly reduces the preparation time for rescue, allowing firefighters to rescue the first time. In the face of disasters, time is money and time. is life.

2. The head and flow can be controlled by adjusting the speed of the engine, and the height and size of the water flow become easier to control. When the nozzle is in a stable state, by controlling the engine, we can accurately spray the water source at the fire point to extinguish the fire, which also reduces the difficulty of rescue for firefighters.