Diesel engine fire pump with strong overload capacity

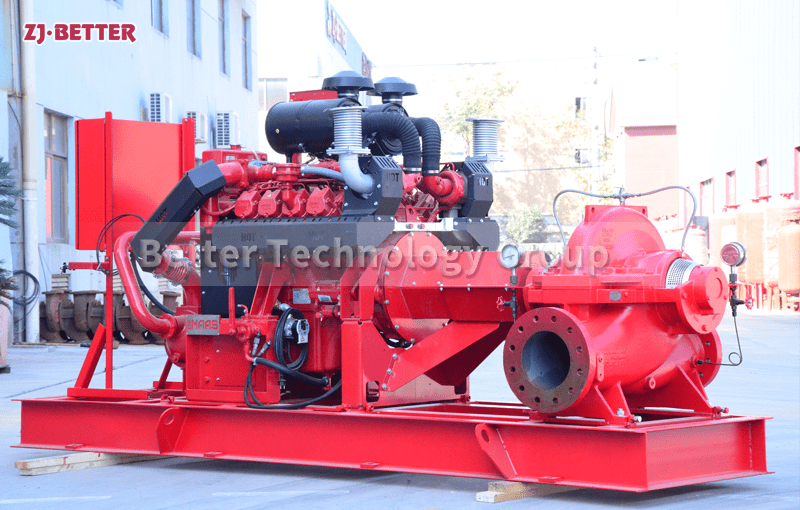

Diesel engine fire pumps are used for fire-fighting water supply in large-flow, high-lift occasions, and the diesel engine has good starting characteristics, fast starting speed, strong overload capacity, energy saving and does not need to be on standby all the time. The fire pump has complete performance and wide spectrum range. Single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps and long-axis pumps can also be used in parallel and combined, with wide flow and pressure ranges. Fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises.

The biggest difference between the diesel engine fire pump and the electric water pump is that it has its own independent power supply system, which can ensure the normal operation of the project without power or power supply. Its role is self-evident, and it can be said to be a great helper in fire emergency .

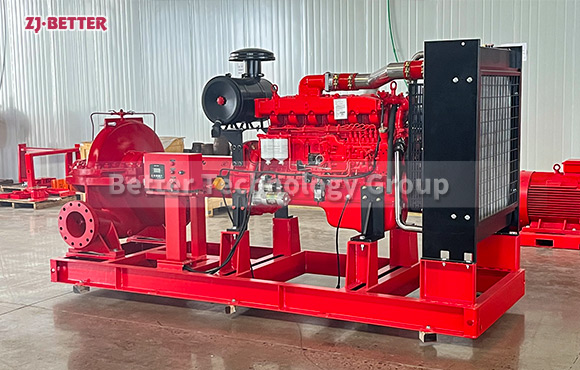

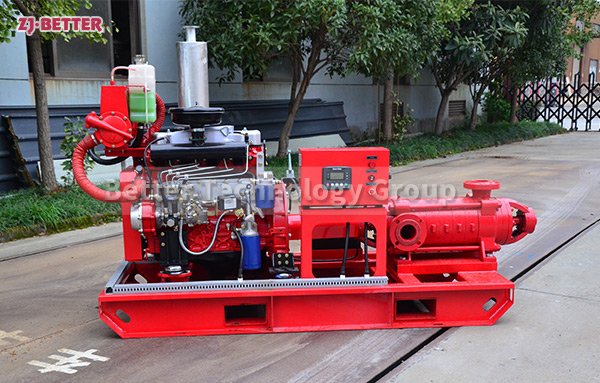

Structurally, the diesel engine fire pump is mainly composed of diesel engine, fire pump, connection device, fuel tank, radiator, battery, intelligent automatic control panel and so on. And at present, the diesel engine fire pumps are equipped with the time-limit automation function of the control cabinet. The start and operation of the diesel engine completely rely on the traditional operation mode, and realize the functions of remote control, automatic start, ultra-low voltage start and automatic alarm.