Diesel engine fire pump set has a high degree of automation

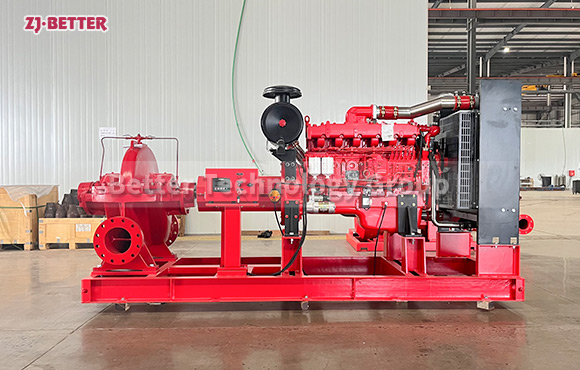

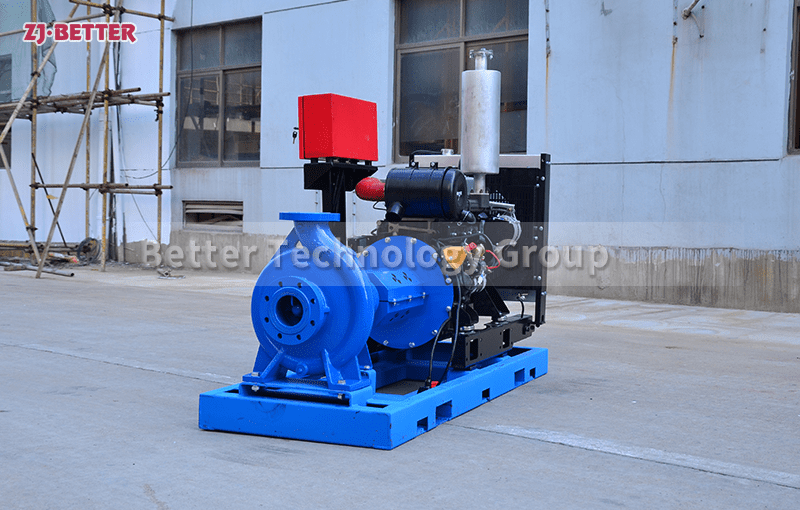

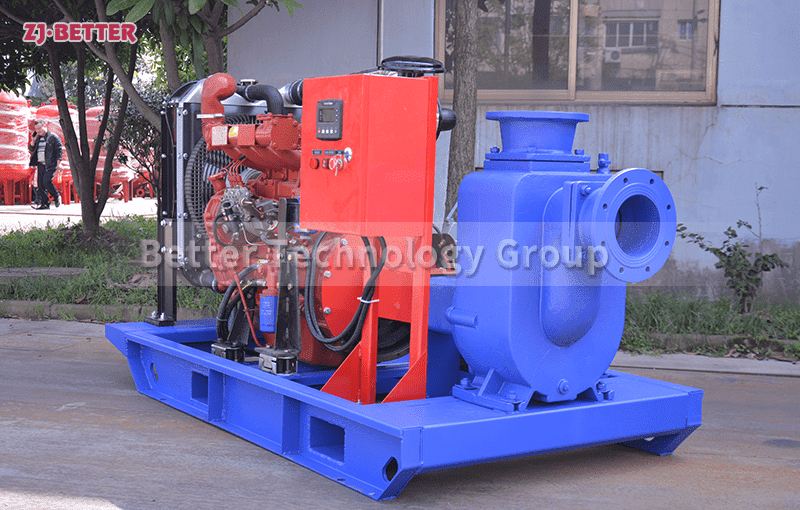

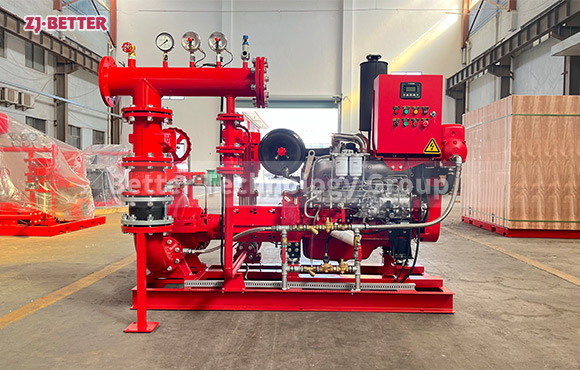

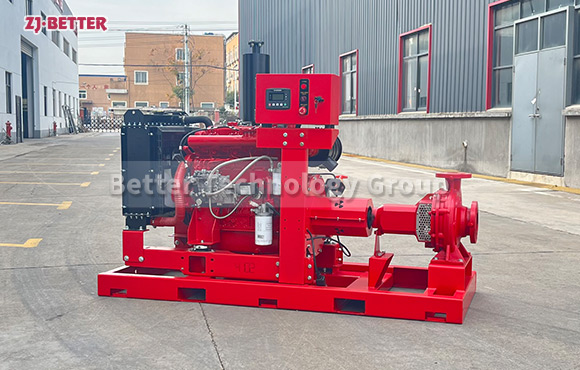

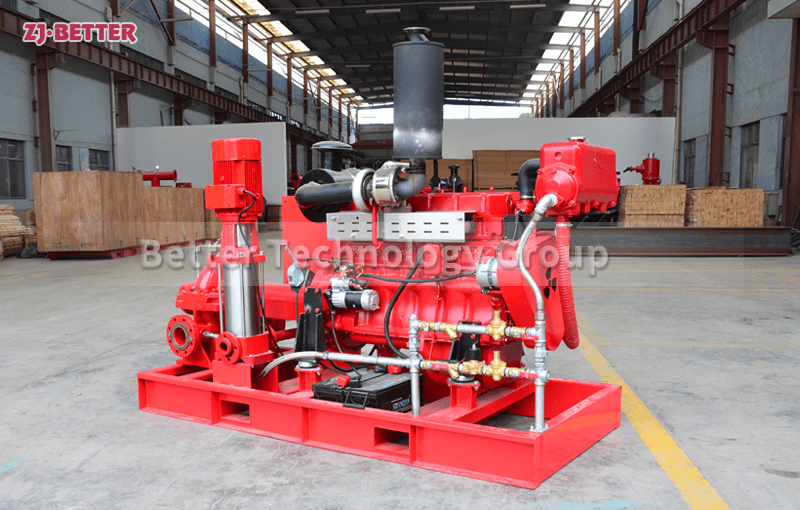

As a fixed fire-fighting equipment, the diesel engine fire-fighting pump set has been widely used in fire-fighting diversion, especially for fire-fighting water supply in unexpected situations such as no power supply or abnormal power supply (mains power). The fire pump equipped in the unit is a horizontal single-stage and multi-stage fire-fighting special pump. It is mainly composed of diesel engine, fire pump, connection device, fuel tank, radiator, battery pack, intelligent automatic control panel, etc.

The intelligent diesel fire pump products produced by our company are equipped with an unattended intelligent system as standard. The product has the characteristics of mature technology, high degree of automation, superior performance, complete protection functions, reasonable structure, simple installation and high cost performance. At the same time, in order to meet the different needs of users and reasonable investment, the products are divided into multiple application series such as fire pumps, industrial emergency pumps, agricultural water pumps, marine water pumps, trailer mobile water pump stations, etc., which can be linked and switched with electric fire pumps. Supporting water pumps: single-stage fire pump, multi-stage fire pump, single-stage split double-suction fire pump.