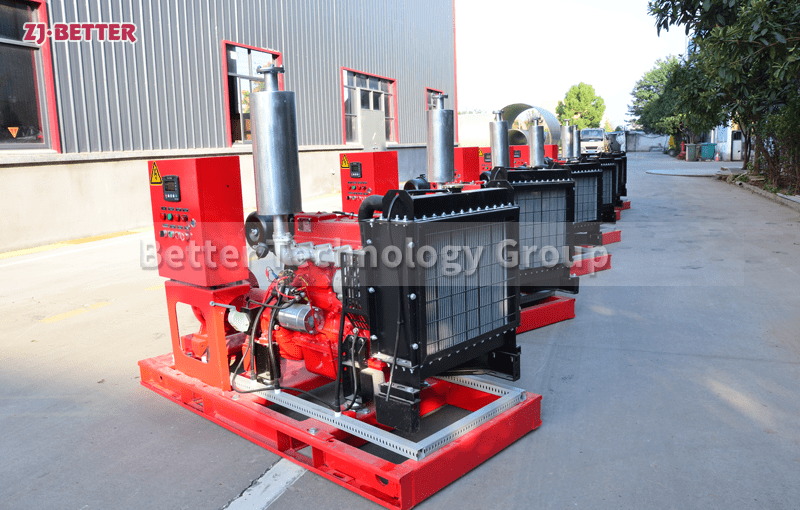

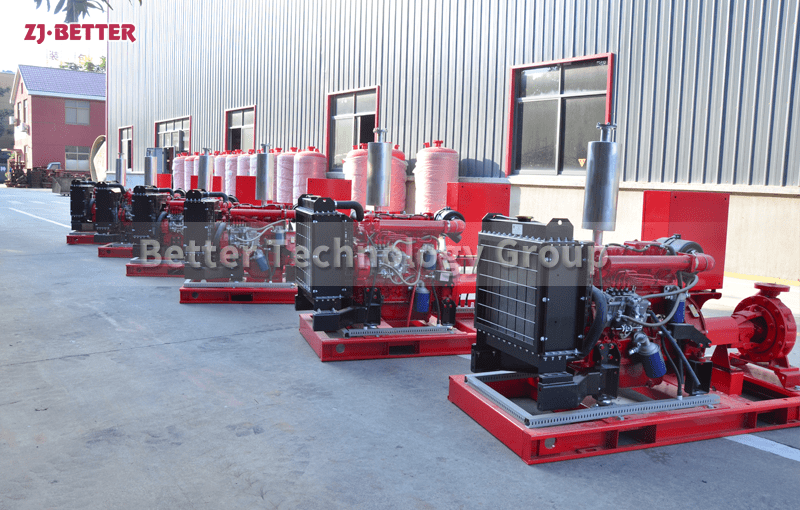

Fueling Fire Safety: The Unrivaled Efficiency of Diesel Engine Fire Pumps

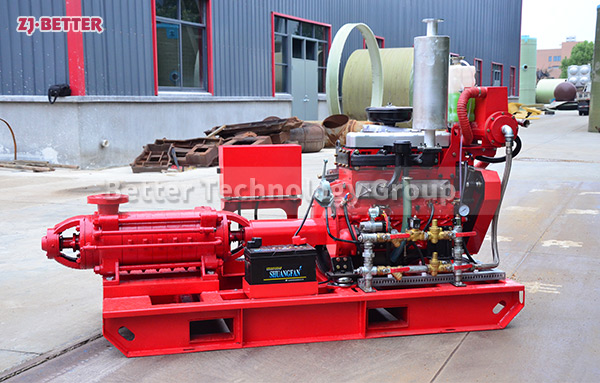

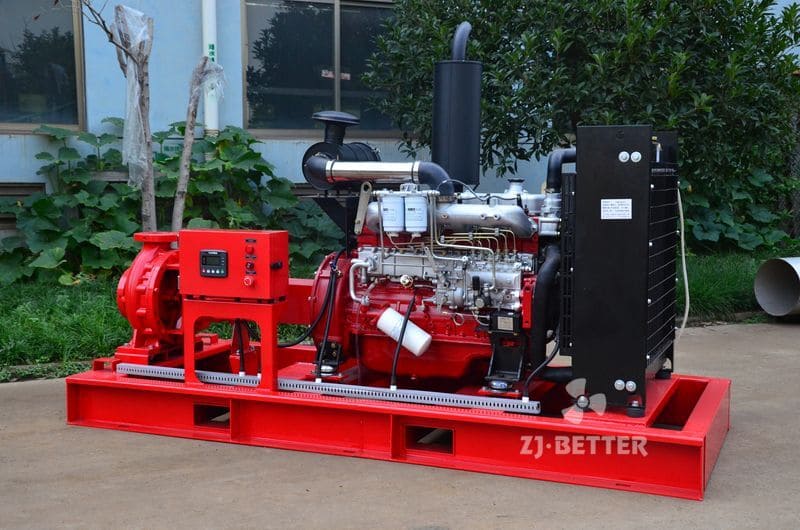

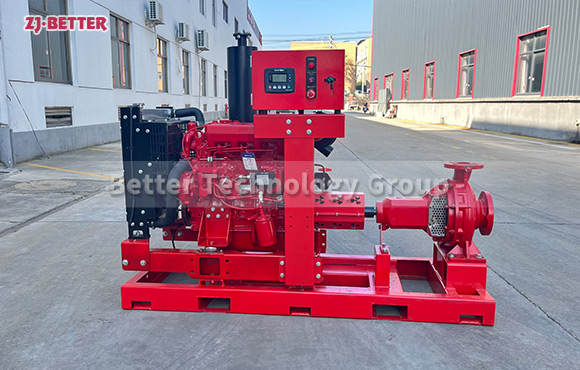

Diesel engine fire pumps offer unmatched efficiency and reliability in fire safety. With powerful diesel engines at their core, these pumps deliver high-pressure water flow to effectively combat fires. They operate independently of the electrical grid, ensuring uninterrupted functionality during power outages. Widely applied in building fire suppression, oil fields, and marine facilities, these pumps provide critical firefighting capabilities. Innovative features like automated control systems and energy-saving technologies further enhance their performance and sustainability. Diesel engine fire pumps are the epitome of efficient fire safety solutions.

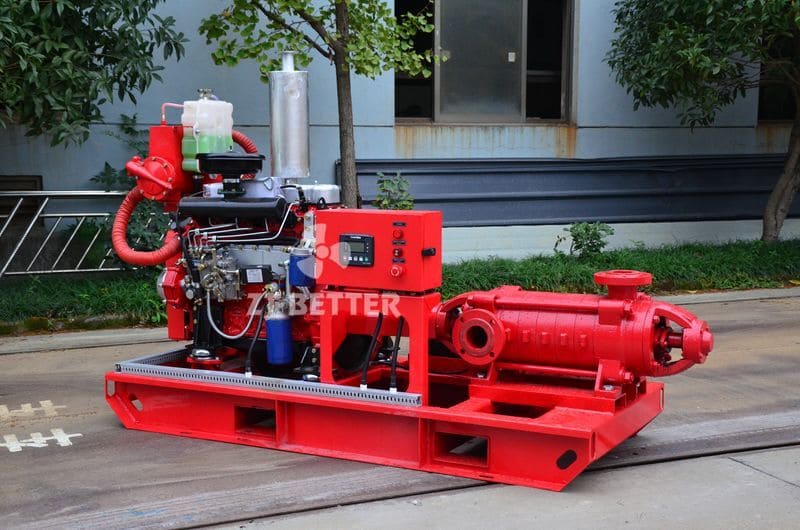

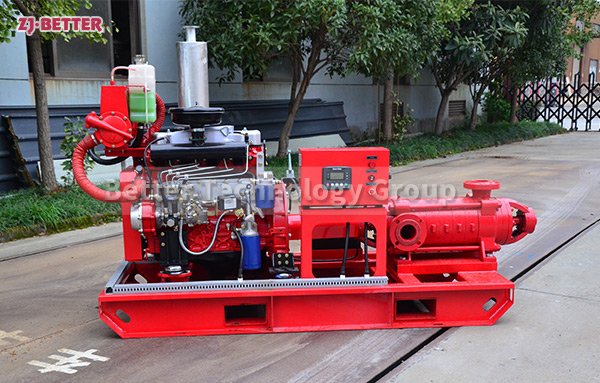

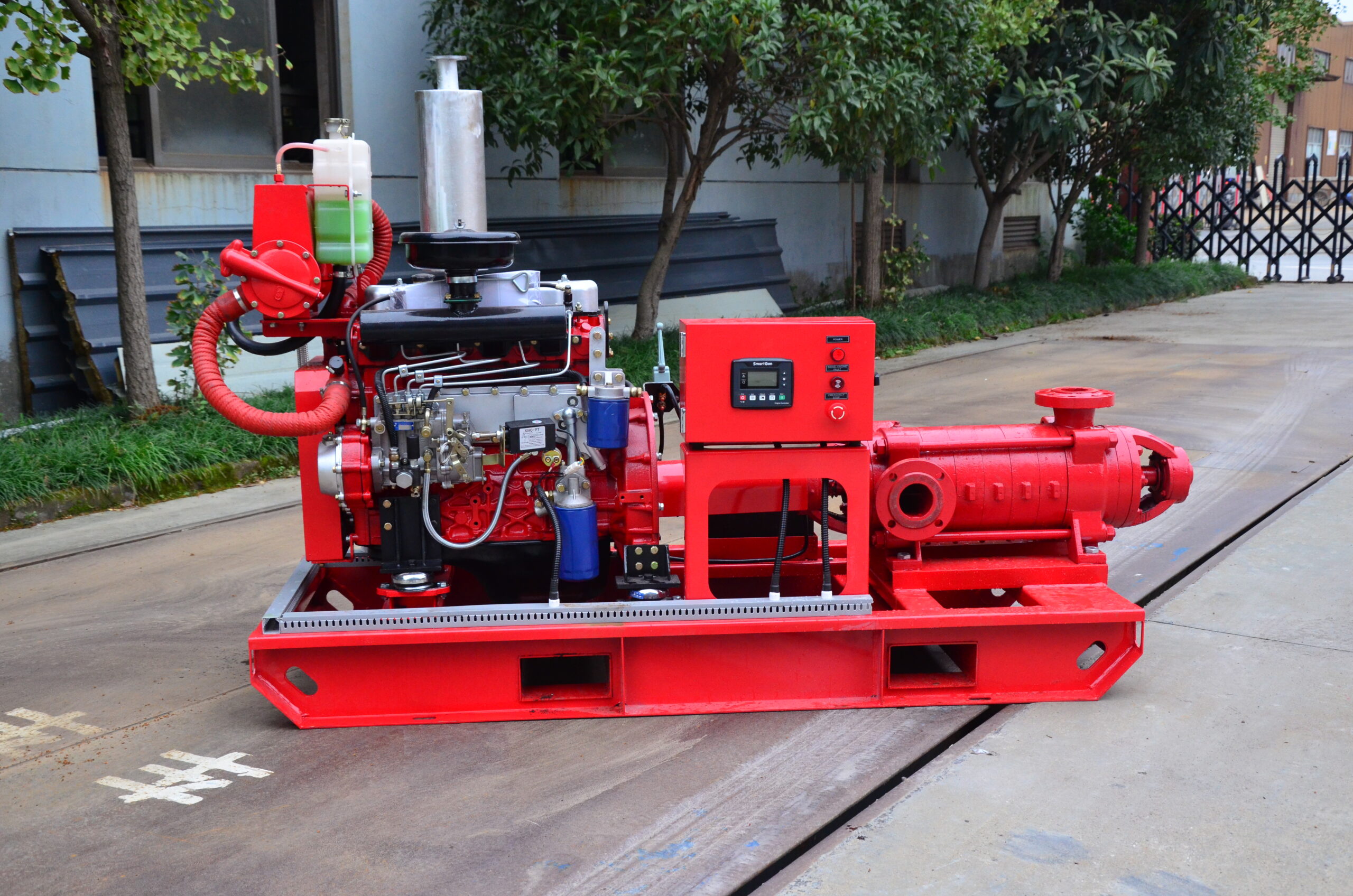

When a diesel engine fire pump is started, the diesel engine begins to run and drives the water pump through a transmission device. The water pump of the diesel engine fire pump draws water from the water source and undergoes a process of pressure enhancement to push the water into the firefighting system. The power provided by the diesel engine enables the water pump to generate high-pressure water flow to meet the fire suppression requirements.

Diesel engine fire pumps are typically equipped with control systems to monitor and regulate the pump’s operation. These systems can automatically start and stop the pump, adjusting the water flow and pressure according to the needs of the firefighting system. Diesel engine fire pumps are also commonly equipped with protective devices such as overheating protection and pressure protection to ensure the safe operation of the equipment.

During the operation, regular maintenance and servicing of the diesel engine fire pump are necessary, including inspections and replacements of lubricating oil, fuel filters, etc. This helps to ensure the proper functioning of the diesel engine and the reliability of the fire pump.