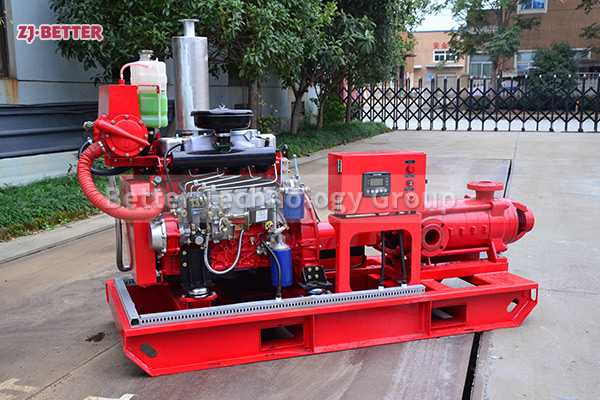

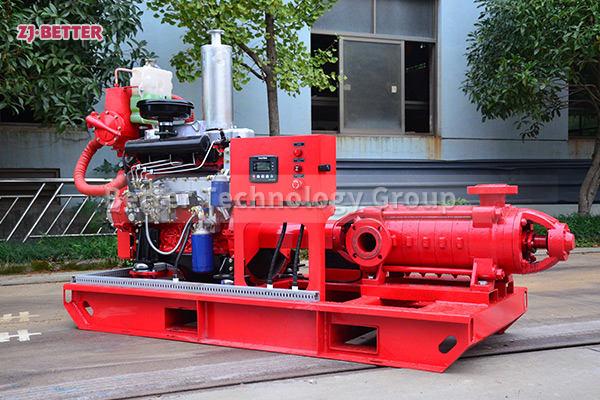

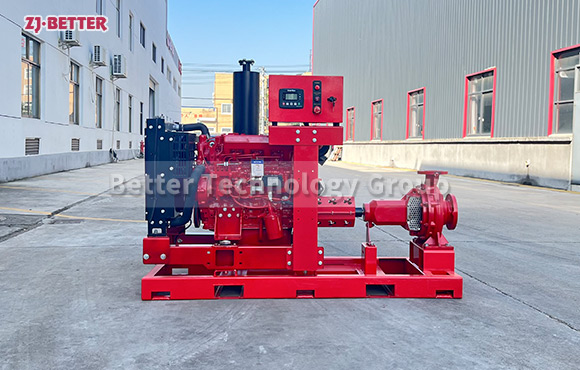

Multistage fire pump with compact structure

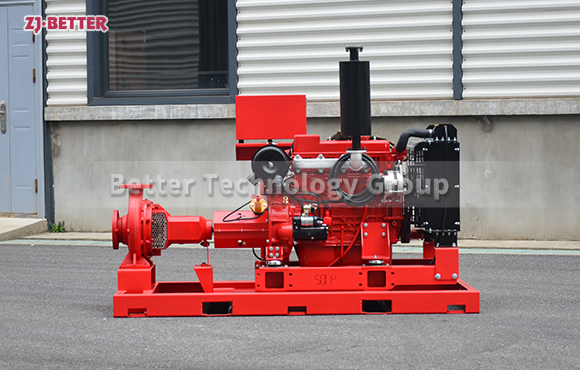

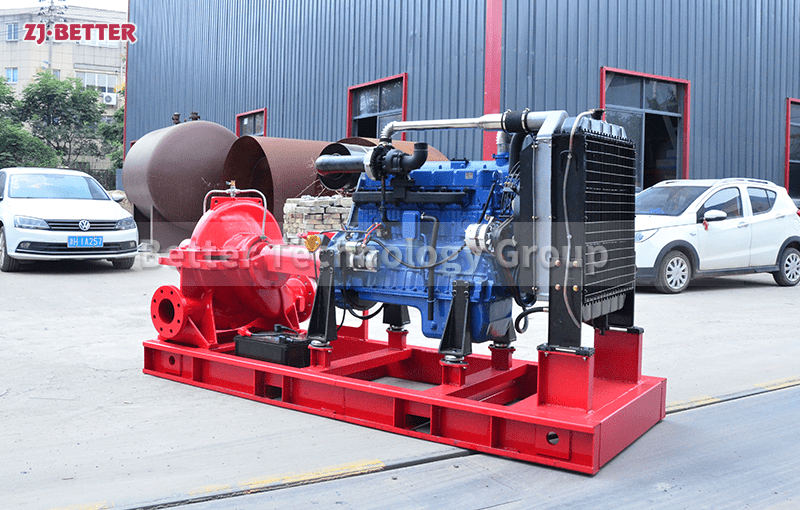

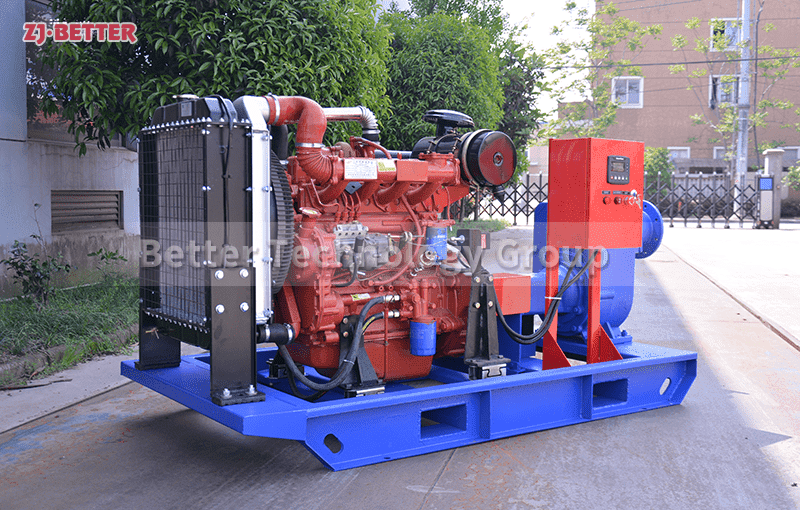

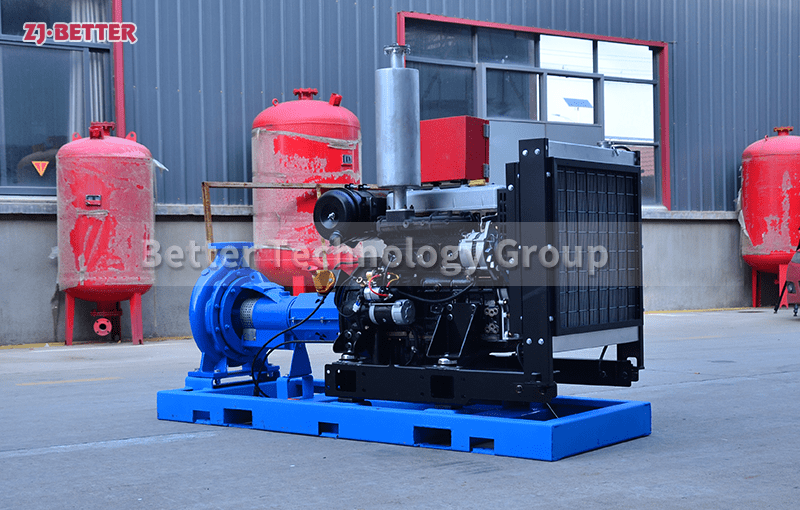

There are many types of fire-fighting equipment. Fire hydrants and fire extinguishers are the most common types. The other is the fire pump, which is the heart of the fire-fighting system and plays an important role in pressurizing and supplying water to the fire-fighting system. Among the numerous fire pump products, fire pumps can be divided into multi-stage and single-stage fire pumps.

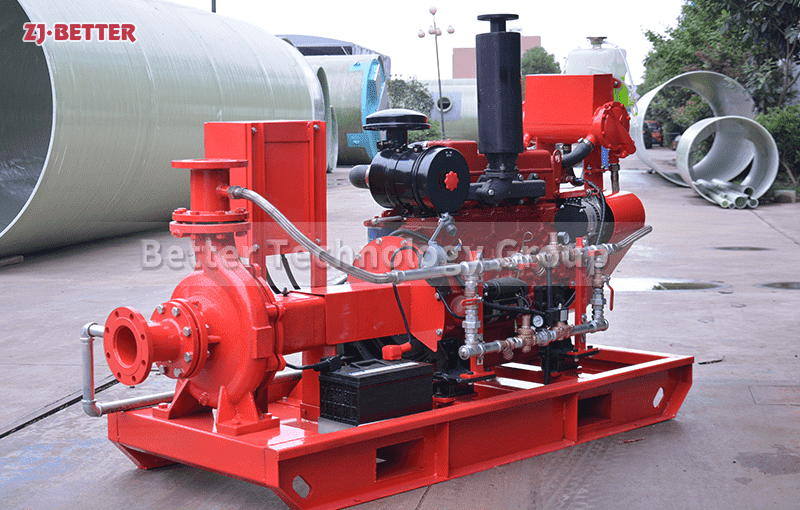

The multistage pump has high efficiency, corrosion resistance, reliable operation and other performances. The pump body has strong bearing capacity, strong anti-overload ability, and relatively sensitive start-up. The multi-stage pump has the characteristics of compact structure, small spacing between parts and small volume. The operation of the equipment is stable, the service life is long, and the vibration generated during operation is small, so the practical life of the equipment is relatively long.

With its unique structure, the direction of the water inlet and outlet can be adjusted according to different needs, so it is suitable for various places and environments. Moreover, the direction of the water inlet and outlet is horizontal, and the bending of the pipeline is reduced in the connection of the pipeline, thereby simplifying the connection of the pipeline and greatly enhancing the efficiency of the fire protection system.