In the fire fighting pipeline pump, according to the different installation methods can be divided into vertical fire pumps and horizontal fire pumps, many people have questions about these two common pumps, what is the difference between the two? Shanghai Xizhiquan will explain the difference between horizontal and vertical pumps.

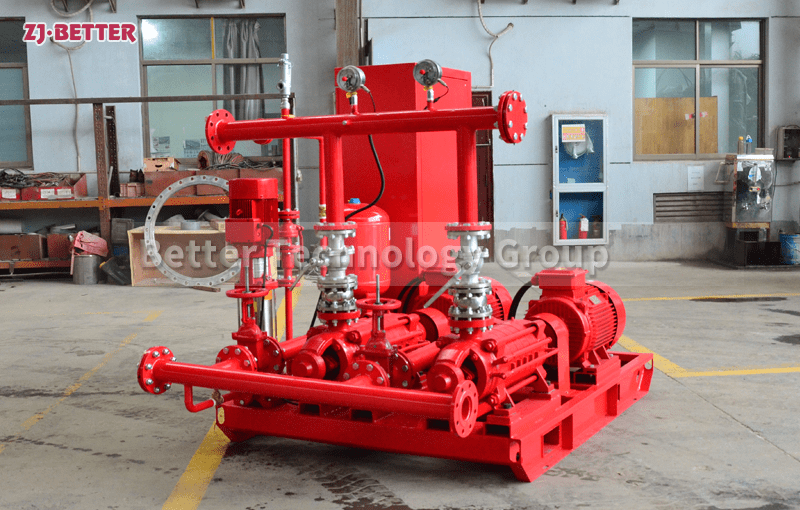

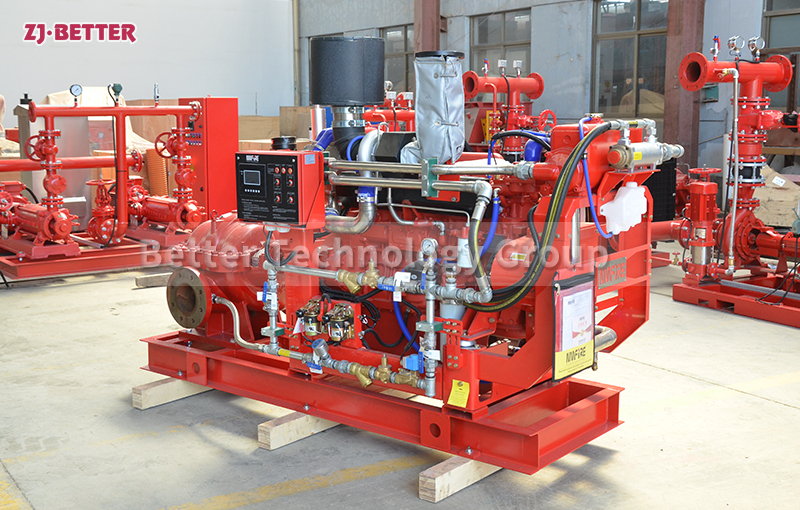

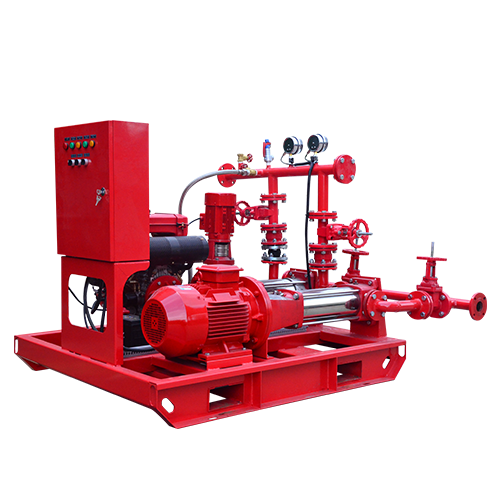

Obviously, different installation methods take up different space. Vertical pipeline pumps are installed vertically, covering a relatively small area, and vertical fire pumps do not require a foundation, while horizontal fire pumps need to be equipped with a base.

According to the different structures of the two pumps, it can be concluded that there is also a certain difference in the ease of maintenance of the two types of fire fighting pipeline pumps. The impeller of the vertical fire pump needs to be dismantled from top to bottom, which makes maintenance more difficult; the horizontal fire pump only needs to have the inlet pipe removed so that the impeller can be overhauled, which is relatively simple.

Due to the different inlet and outlet pipe directions, the pipeline connection between vertical and horizontal is also different. As the vertical pump is a bottom-up structure, while the horizontal fire pump is longitudinally arranged on the base, so the motor of the vertical pump and the pump body are connected in the form of sub-mouth connection, while the horizontal pump needs to use couplings to connect with the motor, and the horizontal pipeline pump needs to be corrected regularly.

Translated with www.DeepL.com/Translator (free version)