What should be paid attention to for the EJ fire pump set that is easy to operate?

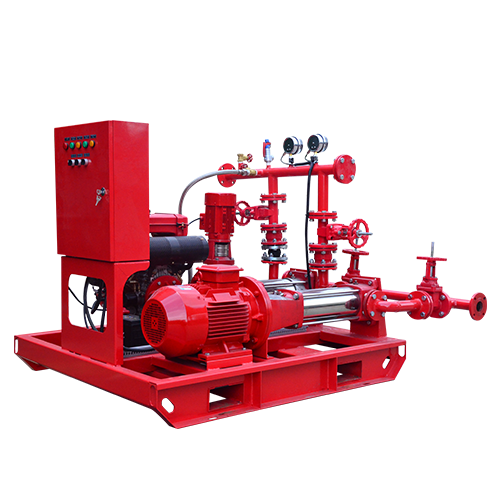

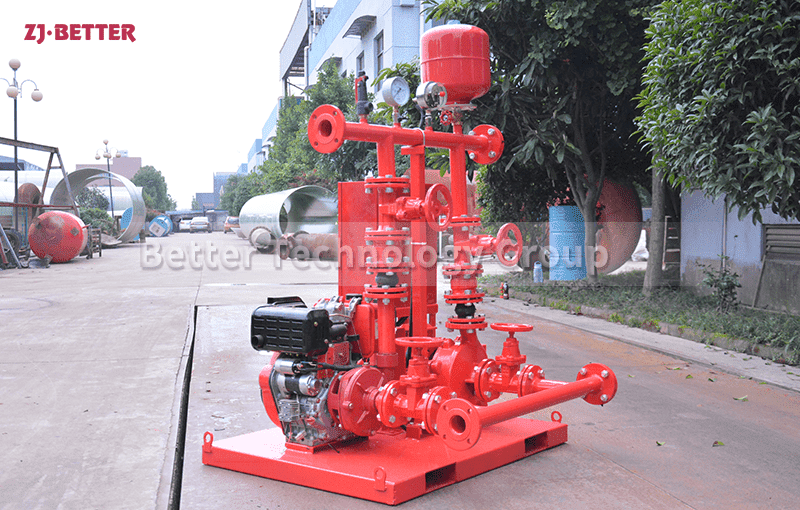

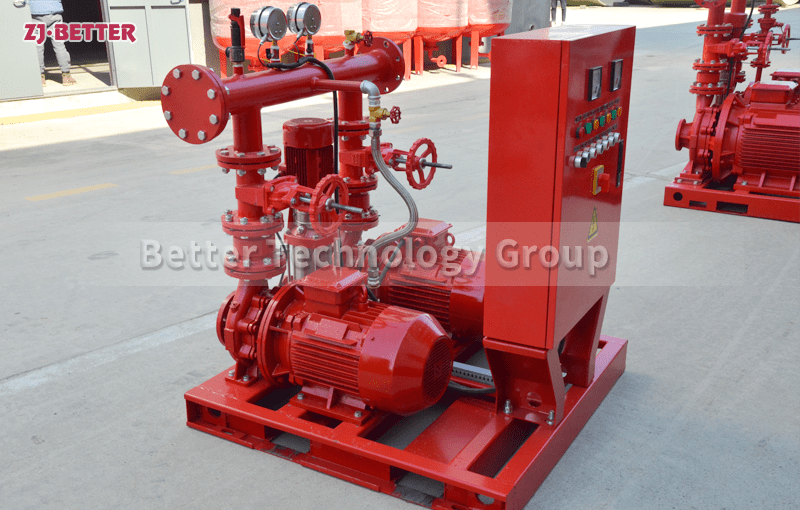

Electric motor fire pumps are used in various water environments, not only to meet the general water supply but also to be a good helper for fire water. The electric motor fire pump is manufactured with good structure and workmanship. It has a wide range of performance, and is easy to use and operate for a long time. The motor fire pump is aimed at various fire water environments, so the selection should also be based on the actual demand environment, performance parameters, etc.

The inspection work of the electric motor fire pump is mainly composed of various components, such as the motor, pump base, coupling, bearing, shaft, sealing device, impeller, etc. The corresponding inspection and maintenance records must be done well, and the records are for better use of fire protection pumps. The pump is also a good basis for finding sudden failures, and the long-term use of the electric motor fire pump is more stable.