Types of fire pumps

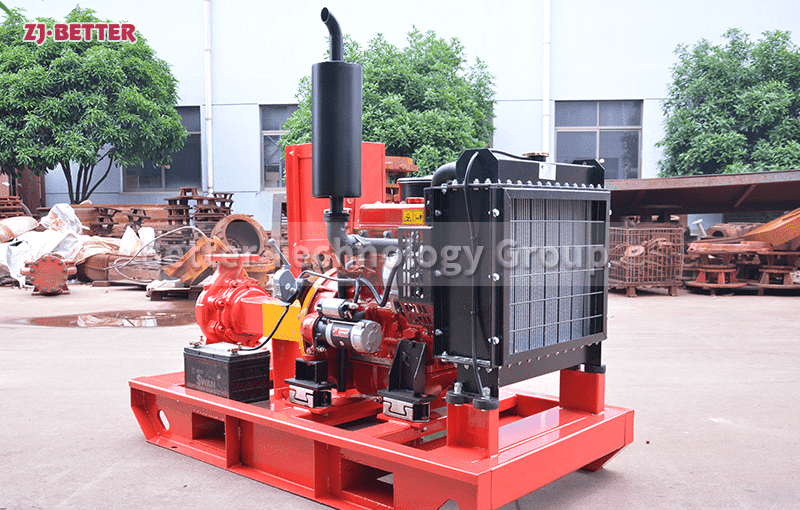

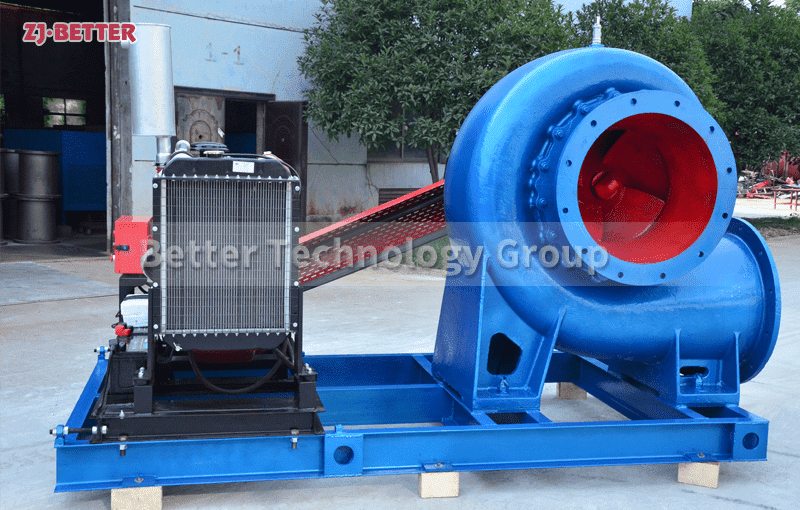

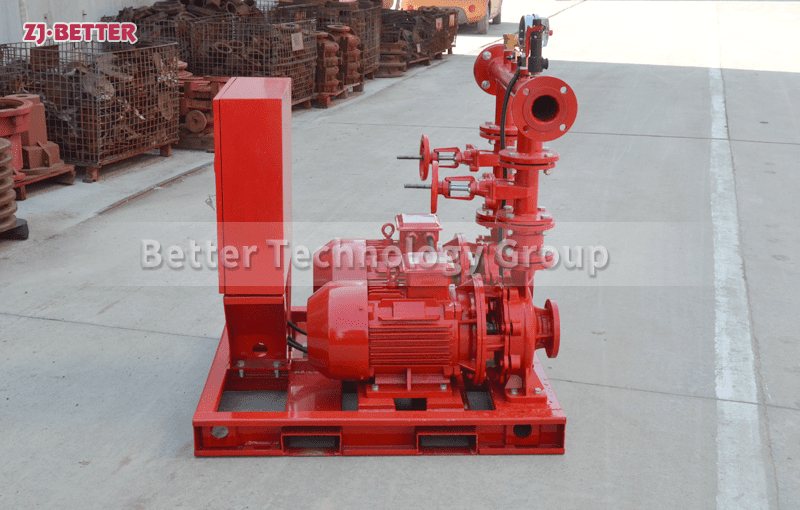

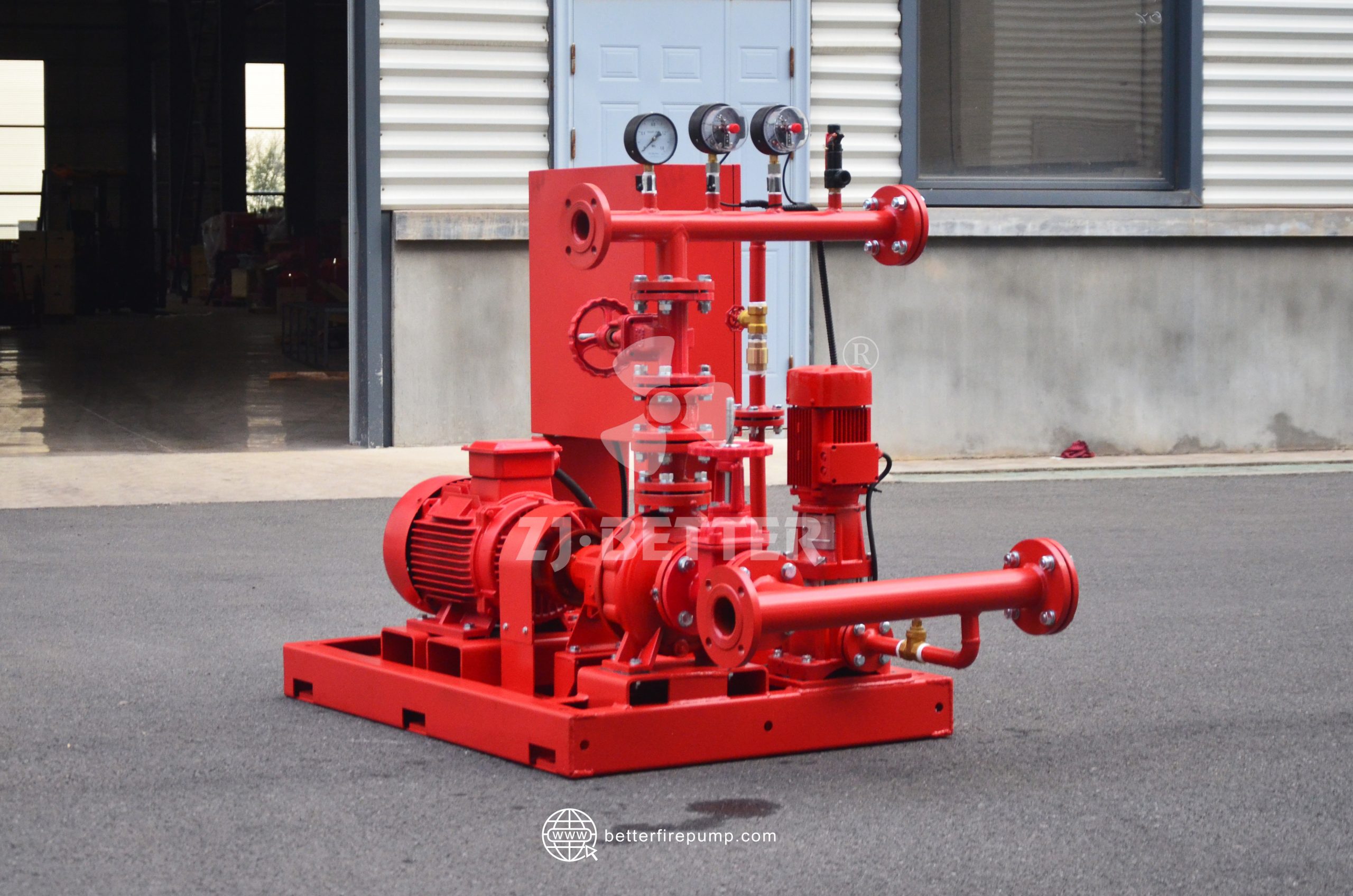

There are four types fire pump, including end suction pump, split case pump, multiage pump and vertical turbine pump. These fire pumps may bepowered by an electric motor or diesel engine and on rare occasion powered by a steam turbine.

Horizontal split case pumps: the most commonly used type of pump. This is due to their ease of access to all working parts, availability of various sizes, ability to efficiently move large amounts of water, and their long term dependability. This type of pump requires a water source that provides a positive suction pressure.

End suction pump: ISW (in-line), cost-effective

Multistage pump: Multiage pump with high lift, greater than or equal to 120M

Vertical turbine pump: this type of pump is able to operate without priming. The typical supplies for these pumps are underground tanks or wells. When operating, these pumps force water up through the column pipe to the pump discharge.