Fire pump refers to the clear water pump used for fire water supply

The fire pump is mainly used for various fire hydrants and spray fire main pumps. It is also suitable for various fire booster and pressure stabilizing pumps. It is also suitable for various villas, residential areas and other fire protection systems, industrial and civil The building fire protection system is also suitable for various oil depots, oil loading and unloading docks, logistics parks and other places with high fire protection requirements.

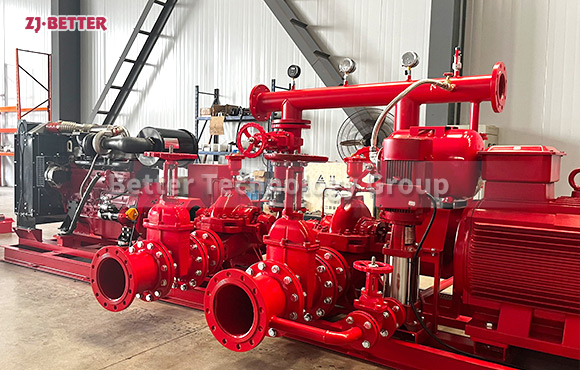

Fire pump refers to a clean water pump used for fire water supply, and a single water pump with a treatment medium temperature lower than 80 degrees and non-corrosive. The pump unit is a joint operation of multiple fire pumps to ensure the quantity and stability of water supply. The electric motor fire pump set adopts multiple fire water pumps powered by electric motors. The general fire water supply environment is equipped with one electric and one diesel fire pump as the reserve water pump to ensure sufficient emergency water consumption. The main components of the electric motor fire pump set are the motor and the pump body. The subdivision of the pump body is the pump casing, impeller, pump shaft, bearing, coupling, sealing form, water pipe, etc. The specific fire pump model is determined according to the environment and performance requirements. At the same time According to the material quotation required by the customer, accurate selection is conducive to on-site use and reduces failure problems.