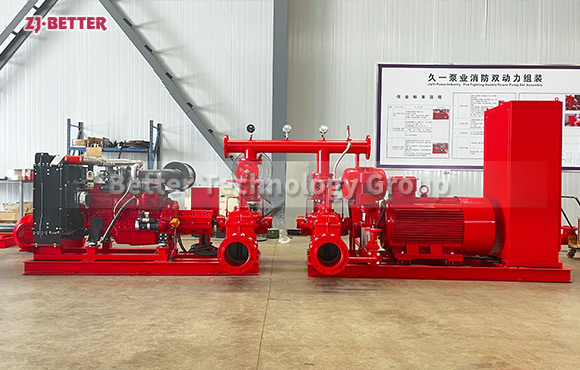

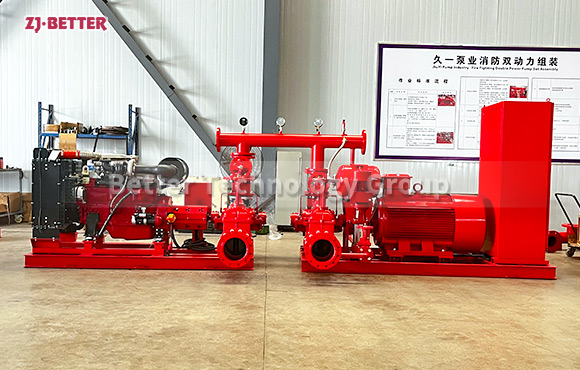

Packaged Electric Fire Pressure Pump Solution for Modern Building Fire Systems

Packaged electric fire pressure pump systems designed for modern building fire protection, providing stable pipeline pressure, automatic control, low energy consumption, reliable operation, and long service life for sprinkler and hydrant systems.

Complete sets of electric fire-fighting pressure-stabilizing pumps are an indispensable and important component of modern building fire protection systems. They are primarily used to maintain a constant pressure in the fire protection network during non-fire conditions, ensuring the system is always in a reliable operating condition ready for immediate start-up. This buys valuable time for the main fire pump to start and for overall water supply in the event of a fire. These devices typically use an electric motor as the power source and are equipped with a dedicated fire-fighting pressure-stabilizing pump, pressure tank, pressure control device, electrical control cabinet, and related valves and instruments. The overall structure is compact and rationally laid out, enabling multiple functions such as pressure stabilization, monitoring, and automatic control within limited space. They are particularly suitable for fixed fire protection systems in high-rise buildings, commercial complexes, residential communities, hospitals, schools, underground garages, and various industrial plants. Electric fire-fighting pressure-stabilizing pumps are designed with the high reliability and stability requirements of fire protection systems in mind. The pump body is mostly made of high-strength cast iron or ductile iron, possessing excellent pressure resistance and impact resistance. The internal flow channel is hydraulically optimized to reduce hydraulic losses and improve operating efficiency. Even under long-term low-flow operation, it can maintain stable operation, avoiding equipment wear caused by frequent start-ups or low efficiency. The motor section typically uses a specialized motor with excellent insulation and protection ratings, capable of withstanding the relatively humid or temperature-fluctuating environment of the fire pump room. It is not prone to overheating during long-term operation, ensuring continuous and stable operation of the pressure-stabilizing pump year-round, 24/7. The control system is one of the core advantages of the complete set of equipment. It is usually equipped with an intelligent pressure control module that monitors real-time pressure changes in the fire pipeline network using high-precision pressure sensors. When the system pressure drops due to minor leaks, temperature changes, or pipeline water replenishment needs, the pressure-stabilizing pump automatically starts to replenish the pressure. It automatically shuts down once the pressure returns to the set range, achieving fully automatic unattended operation. This effectively avoids frequent starts of the main fire pump due to small pressure fluctuations, thereby extending the service life of the main pump and its motor, and reducing overall system maintenance costs. Compared to traditional manual or semi-automatic pressure stabilization methods, the complete set of electric fire pressure-stabilizing pump equipment has significant advantages in response speed and control precision. It starts quickly and adjusts sensitively, completing pressure compensation in a very short time, ensuring the fire protection system always remains within the static pressure range required by regulations, providing reliable basic pressure for sprinkler systems, fire hydrant systems, and other systems. In terms of structural design, these devices mostly adopt an integrated base installation method. All components are pre-assembled and tested before leaving the factory, requiring only simple piping and power connections on-site for immediate use. This significantly shortens the construction cycle, reduces installation difficulty, and minimizes potential hazards caused by improper on-site assembly. The pressure stabilizing tank, as a crucial component of the complete system, acts as a buffer between the start-up and shutdown of the pressure stabilizing pump, absorbing pressure fluctuations, reducing water hammer, and playing a positive role in protecting the pipeline network and valves. It also further enhances the stability and comfort of system operation. From an operational perspective, electric fire-fighting pressure-stabilizing pumps are known for their low power and low energy consumption. During the daily pressure stabilization phase, they only operate briefly when necessary. Compared to the high-power operation mode of the main fire pump, their energy consumption is extremely low, meeting the requirements of modern buildings for energy conservation and operating cost control. Simultaneously, their noise level is relatively low, which helps improve the pump room and surrounding environment. In terms of safety, complete sets of equipment are typically equipped with comprehensive electrical protection functions, including overload protection, phase loss protection, short circuit protection, and fault alarms. Once an abnormal operating condition occurs, the control cabinet can promptly cut off the power supply and issue an alarm signal, alerting management personnel to conduct inspections and maintenance, preventing the equipment from operating with faults and causing greater risks. During long-term use, electric fire-fighting pressure-stabilizing pumps, due to their stable operating conditions, low load, low mechanical wear, and relatively long maintenance cycles, only require periodic checks of pressure settings, electrical components, and seals. Overall, the maintenance workload is small, making them suitable for the long-term needs of property management units and industrial users. From the perspective of the overall fire protection system, although complete sets of electric fire-fighting pressure-stabilizing pump equipment do not directly undertake the task of supplying large volumes of water during firefighting, they play an irreplaceable role in maintaining the system’s availability and ensuring the reliability of initial water supply. They are crucial foundational equipment for ensuring that the fire protection system meets regulatory requirements and operates safely. With the continuous increase in building height and scale, and the increasingly stringent fire safety standards, the importance of electric fire-fighting pressure-stabilizing pumps in the system is becoming increasingly prominent. Their standardization, complete sets, and intelligent development trends are also becoming more evident, better meeting the comprehensive needs of modern building fire protection systems for reliability, stability, and automation. In summary, complete sets of electric fire-fighting pressure-stabilizing pump equipment, with their advantages of compact structure, stable operation, precise control, low energy consumption, and easy maintenance, have become an indispensable key component of modern fixed fire protection systems, providing a solid and lasting foundation for building fire safety.