Performance Analysis of Diesel Fire Pump Sets for High-Standard Fire Protection Requirements

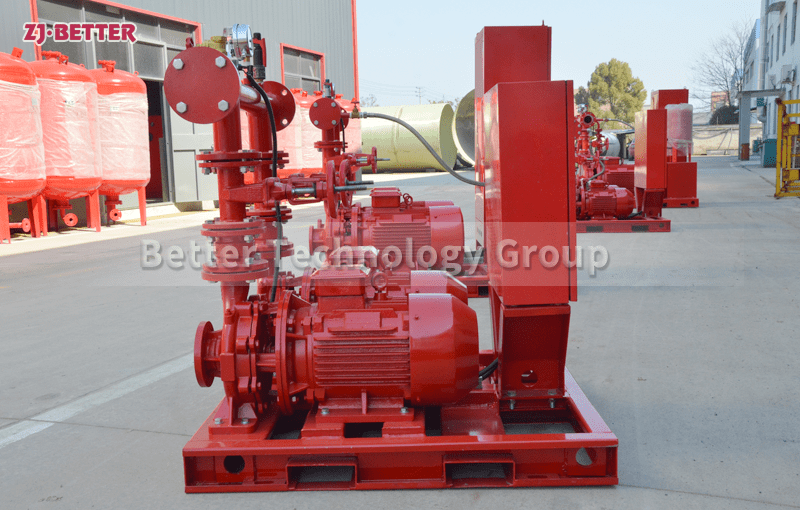

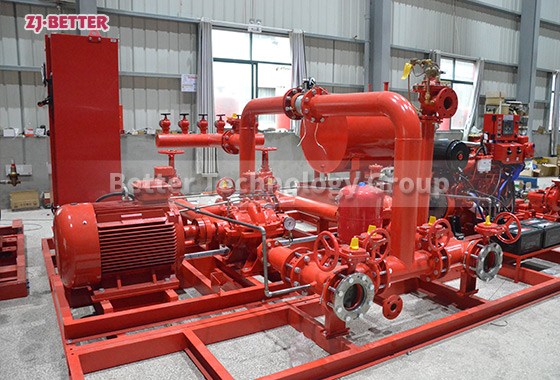

This high-standard diesel fire pump system integrates diesel power, a dedicated fire pump body, and a fully automatic control system. It features rapid start-up, stable high-pressure and high-flow output, and independent operation during mains power outages. It is suitable for high-rise buildings, industrial plants, and large-scale fire protection projects.

Diesel fire pump systems designed for high-standard fire protection play a crucial role in modern fire protection systems. Their design aims to maintain a stable, reliable, and continuous water supply even under the most severe and uncontrollable fire conditions, thus buying precious time for personnel evacuation, fire control, and property protection. These systems typically integrate a high-performance diesel engine, a dedicated fire pump body, a fully automatic control system, a cooling system, a fuel system, an exhaust system, piping components, and necessary safety and monitoring devices. The overall structure is compact and rationally laid out, enabling independent operation even in the event of a power outage or electrical system failure. This fully meets the stringent requirements of high-standard fire protection projects for “ready to start, continuously operable, and without performance degradation.” In terms of performance, the equipment utilizes a pump body structure optimized for fire protection conditions, with a scientifically designed flow channel and superior hydraulic performance. It can quickly establish stable pressure and flow at rated speed, meeting the actual needs of different fire protection systems for high flow rates, high heads, or long-term continuous water supply. Simultaneously, it maintains good efficiency and cavitation resistance under partial load or sudden change conditions, ensuring safe and reliable system operation. The diesel power unit utilizes a mature and stable engine platform, boasting advantages such as rapid start-up, ample torque reserve, and strong fuel adaptability. Even in low-temperature, high-humidity, or dusty environments, it maintains excellent operating performance. Combined with a dedicated starting system and energy storage device, it provides dual protection through multiple automatic starts and manual emergency starts, significantly reducing the risk of system failure due to start-up failures. To meet the dual requirements of intelligence and reliability in high-standard fire protection projects, this type of diesel fire pump system typically features a fully automatic control cabinet. The control logic strictly adheres to fire protection system operation specifications, enabling automatic pressure change detection, automatic start-up and shutdown, real-time display of operating status, and multiple alarm functions. When the system pressure falls below the set value, the equipment can start and operate in a very short time. Simultaneously, it continuously monitors key parameters such as oil pressure, water temperature, speed, and battery voltage during operation. In the event of an abnormality, the control system immediately issues audible and visual alarms and records fault information, providing maintenance personnel with clear and intuitive diagnostic information. Compared to traditional decentralized fire-fighting equipment, complete diesel fire pump systems offer significant advantages in installation and commissioning. All key components are pre-matched and integrated before leaving the factory, greatly reducing on-site construction difficulty and commissioning time, effectively mitigating risks associated with human error, and making the entire fire protection system easier to pass acceptance testing on the first attempt. This makes them particularly suitable for projects with extremely high requirements for schedule and reliability. From a durability and stability perspective, these devices also demonstrate high standards in material selection and manufacturing processes. The pump body and key pressure-bearing components are typically made of high-strength, wear-resistant materials, possessing excellent corrosion and fatigue resistance. They can adapt to the frequent switching between long-term static standby and sudden high-load operation. Combined with a well-designed cooling and lubrication system, this effectively extends the overall service life of the equipment and reduces long-term maintenance costs. For different application scenarios, complete diesel fire pump systems offer strong flexibility in system configuration. They can be equipped with voltage stabilizers, backup starting power supplies, remote monitoring interfaces, and various signal output methods according to project needs, facilitating integration with building fire control systems or centralized monitoring platforms for higher-level system management and safety assurance. In practical applications, this type of equipment is widely used in high-rise buildings, large commercial complexes, industrial plants, warehousing and logistics centers, data centers, and infrastructure projects—places with extremely high fire safety requirements. Its independent and reliable power source and stable hydraulic output make it an indispensable main or backup pump solution in fixed fire protection systems. Overall, diesel fire pump systems designed for high-standard fire protection not only possess strong performance parameters but also demonstrate significant advantages in system integration, operational reliability, environmental adaptability, and ease of maintenance. They can operate stably and reliably during critical moments, providing continuous and dependable core power support for fire protection systems. They are one of the essential foundational equipment for achieving safety goals in modern high-level fire protection engineering.