Application Analysis of Horizontal End Suction Electric Fire Pumps as Main Pumps in Fixed Fire Protection Systems

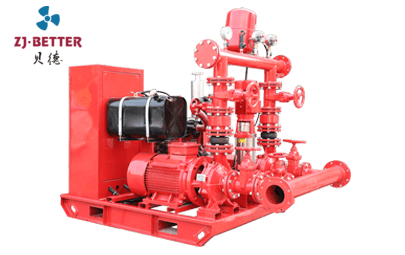

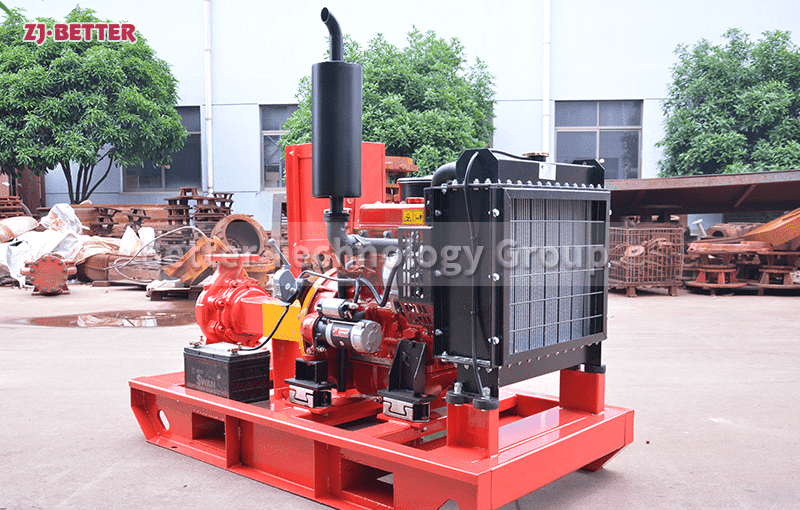

Horizontal end suction electric fire pumps designed as main pumps for fixed fire protection systems, delivering high flow capacity, stable pressure, fast startup, reliable continuous operation, and efficient performance for building and industrial fire safety applications.

The application analysis of horizontal end-suction electric fire pumps as main pumps in fixed fire protection systems requires a systematic explanation of their structural form, operational performance, and reliable performance in engineering practice. These fire pumps typically serve as the core water supply equipment in fixed fire protection systems, undertaking the crucial task of continuously delivering large quantities of fire-fighting water to the entire fire protection network during a fire. The horizontal end-suction structure is a widely used pump type in fixed fire protection systems. Its reasonable inlet and outlet arrangement and simple hydraulic channel help reduce water flow loss and improve overall operating efficiency, offering significant advantages in meeting high flow rate and stable head output requirements. The electric drive mode allows the fire pump to start rapidly upon receiving a fire control signal, with the motor reaching rated speed in a short time. This establishes stable water pressure in the early stages of a fire, providing a reliable water source for fire hydrant systems, sprinkler systems, and other fire protection facilities—a fundamental performance requirement for main pumps in fixed fire protection systems. When used as main pumps, horizontal end-suction electric fire pumps are typically selected precisely based on building size, network resistance, and design flow rate to ensure that design pressure requirements are met even at the most unfavorable points, guaranteeing effective fire extinguishing capabilities in any area of the fire protection system. In terms of pump body structure, horizontal end-suction electric fire pumps are mostly made of high-strength cast iron or metal materials with good pressure resistance. The overall structure is robust and can withstand the long-term operating requirements of fire protection systems under high pressure and high flow conditions, while maintaining stable performance during repeated start-stop and periodic testing. The internal impeller and flow channel are hydraulically optimized to make the water flow smoother and more stable, which not only improves the pump efficiency but also reduces vibration and noise levels during operation, helping to extend the service life of the equipment. As the core power source, the motor is usually selected as a high-reliability model suitable for fire protection conditions, with good insulation and heat dissipation capabilities, and can maintain stable output under high load operating conditions, meeting the dual requirements of continuous operation and rapid response of fixed fire protection systems. The horizontal structure also provides convenience for equipment installation and maintenance. The pump body and motor are arranged on the same horizontal axis, with a clear structure and ample maintenance space, facilitating daily inspection and maintenance management, which is especially important for fire protection equipment that needs to be on standby for a long time. In practical engineering applications, horizontal end-suction electric fire pumps are often integrated with control cabinets, valves, and piping systems to form complete fire pump sets. Through automatic control logic, they are linked with fire alarm systems. In the event of a fire, the system automatically starts the main pump and enters a stable operating state, reducing delays and risks caused by human intervention. To ensure operational stability and safety, these fire pumps are designed with startup impact and smooth operation in mind. By rationally matching motor power and pump parameters, adverse effects on the power system and pipeline network due to excessive starting current or unstable operation are avoided. Fixed fire protection systems typically require fire pumps with long standby capabilities. Horizontal end-suction electric fire pumps demonstrate a significant advantage in this regard, with mature structure, reliable operation, and, with regular testing and maintenance, can maintain good startup performance over many years of use. For large buildings or industrial facilities, the reliability of the fire protection system is directly related to personnel and property safety. As the main pump, the horizontal end-suction electric fire pump provides a solid water supply guarantee for the entire system through stable performance output. In terms of energy consumption and operational economy, these fire pumps, while meeting fire protection performance requirements, reduce ineffective energy consumption through efficient hydraulic design and reasonable selection, ensuring high energy efficiency during testing and actual use. Overall, horizontal end-suction electric fire pumps, with their mature structural design, stable electric drive performance, and extensive application experience in fixed fire protection systems, have become an important choice for main pump configurations. Their comprehensive advantages in high-flow-rate water supply, rapid response, long-term reliable operation, and ease of maintenance enable them to play a core role in various fixed fire protection projects, providing continuous and reliable power support for the safe operation of fire protection systems.