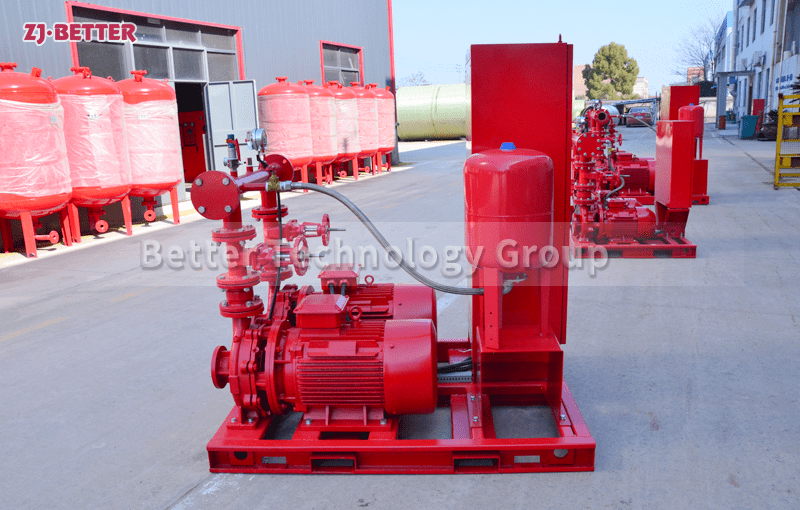

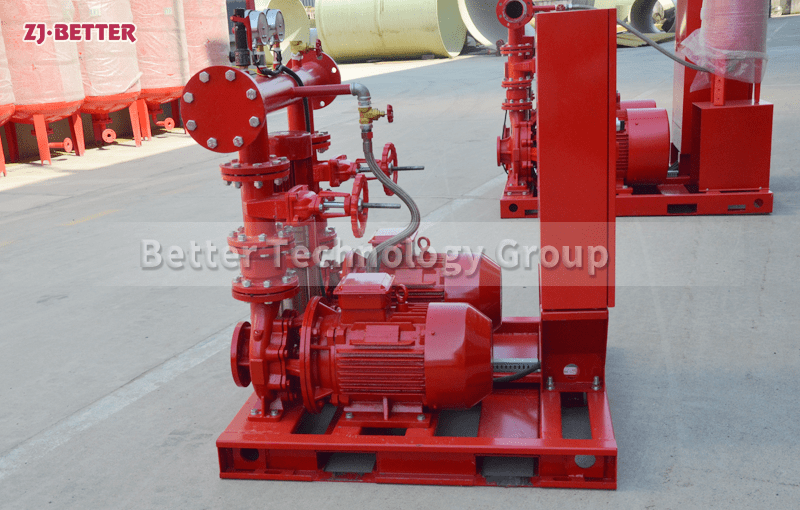

Application Value of Fire Pressure Pump Sets in Fixed Fire Protection Systems

Fire pressure pump sets designed for fixed fire protection systems, providing stable pipeline pressure, reliable standby operation, reduced main pump activation, and efficient performance to enhance overall fire safety and system reliability.

The value of fire-fighting pressure-stabilizing pump systems in fixed fire protection systems lies primarily in their ability to maintain long-term stable control of pipeline pressure and their synergistic operation with the main fire pump system. These devices typically serve as crucial auxiliary units in fixed fire protection systems, continuously maintaining pipeline static pressure to ensure the entire system remains in a safe, ready-to-start state during standby. Fixed fire protection systems are widely used in commercial buildings, industrial plants, warehousing and logistics centers, and public facilities. Their fire pipeline networks are extensive, long, and have significant height differences at their ends. Without stable pressure maintenance devices, pressure drops can easily occur due to minor leaks, temperature changes, or pipeline fluctuations, leading to frequent false starts of the main fire pump. This not only increases equipment wear but also affects the overall reliability of the system. Fire-fighting pressure-stabilizing pump systems are designed to address this need. Through a low-flow, high-sensitivity pressure-stabilizing operation mode, they automatically compensate for pipeline pressure, maintaining a stable pressure level in non-fire conditions, avoiding ineffective start-stop cycles, and providing a reliable standby environment for the main fire pump. In terms of structural design, pressure-stabilizing pump systems typically integrate vertical or horizontal pumps, motors, pressure tanks, pressure sensors, and control cabinets in a highly integrated manner. The overall layout is compact, requiring little floor space, making them particularly suitable for installation in fixed fire pump rooms or equipment rooms. This facilitates centralized management and promotes long-term stable system operation. The pressure tank plays a crucial role in the system, effectively buffering changes in the pipeline network caused by minor water usage or pressure fluctuations by storing a certain volume of pressurized water. This reduces the need for frequent pump starts, extending equipment lifespan and reducing energy consumption. Regarding the control system, fire-fighting pressure-stabilizing pump systems usually feature automatic start/stop and manual control functions. They can intelligently adjust the operating status according to preset pressure ranges. When the pipeline pressure drops to the lower limit, the pressure-stabilizing pump automatically starts to replenish pressure, and automatically shuts down when the pressure returns to the set range. The entire process requires no manual intervention, ensuring the reliability of the fixed fire protection system even in long-term unattended operation. The selection and design of pressure-stabilizing pumps emphasize stable operation and sensitive response. Their flow rate and head configuration prioritize pressure maintenance over high-flow water supply, meeting the pressure stabilization requirements of the pipe network while avoiding excessive hydraulic shock to the system. This is particularly important for high-rise buildings and complex pipe network structures. The motor is typically selected for frequent start-stop conditions, possessing excellent insulation performance and stable output capability, maintaining reliability even under long-term standby and periodic operation. Fixed fire protection systems have extremely high requirements for equipment safety and stability. Fire-fighting pressure-stabilizing pump systems typically adhere to strict standards in material selection and manufacturing processes. The pump body uses pressure-resistant metal materials, and key connections are reliably sealed, capable of withstanding pressure changes during long-term system operation and reducing the risk of leakage and failure. Since the pressure-stabilizing pump system primarily performs auxiliary functions, its operating energy consumption is relatively low. Through reasonable control logic and equipment matching, overall operating costs can be effectively controlled while ensuring system pressure stability. From a maintenance perspective, the fire-fighting pressure-stabilizing pump system has a clear structure. Maintenance primarily focuses on pressure detection element calibration, motor operation status checks, and pressure maintenance of the pressure stabilizing tank. Operation is simple, and maintenance cycles are controllable, contributing to the long-term standardized management of fixed fire protection systems. In practical applications, a clear division of labor exists between the pressure-stabilizing pump and the main fire pump. The pressure-stabilizing pump maintains daily pressure, while the main fire pump only activates during actual fires or when high flow demands occur. This configuration not only improves system response efficiency but also significantly reduces the probability of the main fire pump running dry or malfunctioning. In summary, the value of fire-fighting pressure-stabilizing pump systems in fixed fire protection systems lies not only in their technical pressure control capabilities but also in their comprehensive improvement of the system’s reliability, durability, and operational economy. By stabilizing pipeline pressure, optimizing equipment operation logic, and reducing maintenance risks, it provides a safer, more efficient, and sustainable foundation for the operation of fixed fire protection systems, making it an indispensable and crucial component of modern fire protection engineering.