Stable Output and Continuous Protection: Exploring the Technical Advantages of High-Performance Electric Fire Pumps

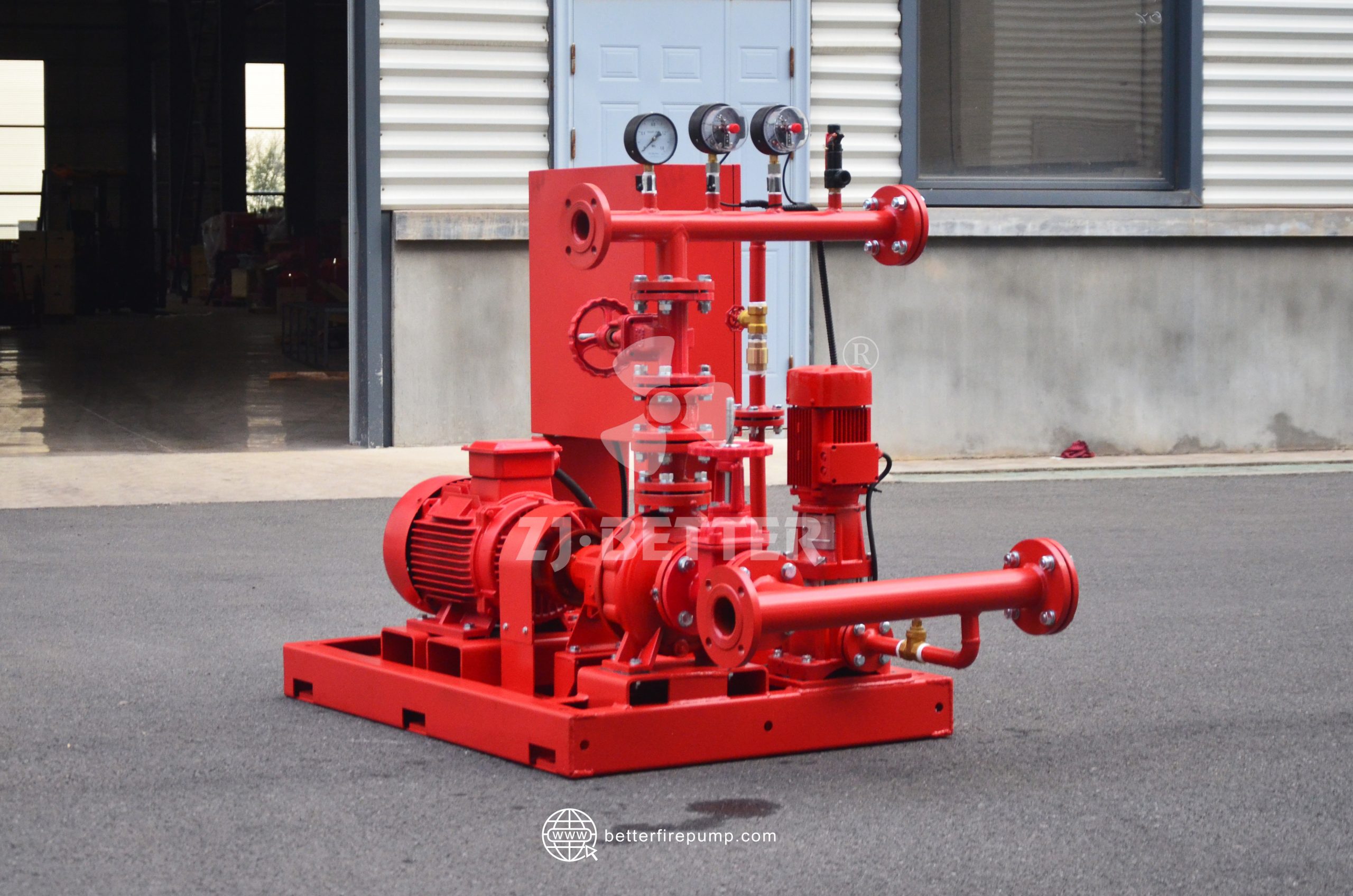

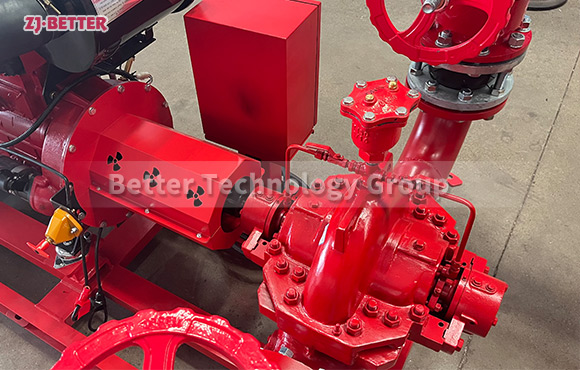

High-performance electric fire pumps feature powerful output, intelligent control systems, and energy efficiency, making them suitable for fire protection systems in high-rise buildings, factories, warehouses, and commercial complexes, ensuring continuous and stable water supply and rapid response. With robust construction, high protection rating, and reliable operation, they are the ideal choice for modern fire safety.

High-performance electric fire pumps, as indispensable key equipment in modern fire protection systems, play a crucial role in ensuring building safety and improving fire response efficiency through their technological advantages and reliability. With the continuous development of industrialization and urbanization, the height and density of buildings are constantly increasing, placing higher demands on the stability of water supply, energy efficiency, and intelligence level of fire protection systems. It is against this backdrop that high-performance electric fire pumps are widely used in various commercial buildings, industrial plants, warehousing and logistics centers, hospitals, airports, and large complexes. With their powerful output, energy-efficient operation, and intelligent control system, they have become the preferred core equipment in modern fire protection systems. The structural design of these electric fire pumps fully considers stability under long-term continuous operation and extreme conditions. The pump body is made of high-strength cast iron or stainless steel, ensuring reliable mechanical performance even under high-pressure transmission and high-temperature environments. The internal impeller undergoes precision dynamic balancing, achieving high flow rate and high head for efficient water delivery, meeting the stringent water supply pressure requirements of fire protection systems of different sizes. The motor adopts a high-efficiency energy-saving design, featuring low noise, low vibration, and high output power density, significantly improving operating efficiency and reducing energy consumption. During long-term operation, electric fire pumps, thanks to their excellent mechanical seal structure, effectively prevent leakage, extend equipment life, and ensure a clean and stable fire water source, avoiding performance degradation caused by leakage or cavitation. In addition to their structural design advantages, high-performance electric fire pumps have also achieved significant technological upgrades in their control systems. Modern electric fire pumps are typically equipped with fully automatic control cabinets, enabling automatic start/stop, pressure monitoring, fault alarms, manual and remote control, and other functions. When the system detects a drop in fire pressure or a fire alarm signal, the electric pump can automatically start in a very short time, providing strong and stable water pressure to continuously support sprinkler systems, fire hydrant systems, and foam extinguishing systems. The intelligent control system can monitor the pump’s operating status in real time, including parameters such as current, voltage, temperature, and water pressure, and collects and analyzes data through PLCs or remote monitoring modules. This allows maintenance personnel to promptly grasp the equipment’s operating status, reduce the risk of sudden failures, and significantly improve the reliability and response speed of the entire fire protection system. High-performance electric fire pumps not only possess excellent power output and intelligent control capabilities, but their energy-saving performance is also particularly outstanding. Employing a high-efficiency motor and optimized hydraulic model design, the pump’s overall energy efficiency is significantly improved compared to traditional equipment, reducing operating costs and aligning with the development trend of modern green and energy-saving buildings. The flow channels of the pump body and pipelines have been optimized through fluid simulation, reducing energy loss and improving delivery efficiency. In fire protection systems operating for extended periods, this energy-saving design not only reduces power consumption but also decreases heat generation, thereby extending the service life of the motor and related components. For fire protection systems requiring 24-hour standby, the high energy efficiency and low maintenance costs of high-performance electric fire pumps are particularly advantageous. Furthermore, these electric fire pumps exhibit a significantly user-friendly design in terms of installation and maintenance. The unit typically uses an integrated base structure, facilitating installation and commissioning and reducing on-site assembly errors; the modular design of the electrical control section facilitates later maintenance and system upgrades. High-quality imported materials are used for mechanical seals and bearings, ensuring low wear and high sealing performance during long-term operation. Simultaneously, the electric pump system possesses multiple protection functions, such as overload protection, phase loss protection, overheat protection, and dry-run protection, automatically cutting off power or issuing alarms even under abnormal operating conditions to prevent equipment damage. For high-rise buildings or industrial parks with extremely high fire safety requirements, high-performance electric fire pumps can be configured in parallel operation with multiple pumps according to actual needs. An automatic switching system between the main and standby pumps ensures uninterrupted water supply. Even if one pump fails, the standby pump can immediately take over, ensuring continuous and stable fire water pressure. This redundancy design greatly improves the system’s reliability and safety, meeting the requirements of various international fire protection standards and engineering specifications. It is worth mentioning that modern high-performance electric fire pumps are widely compatible with intelligent fire protection systems and can interoperate with building automation systems (BAS) or fire monitoring platforms. Through communication interfaces (such as Modbus, RS485, etc.), remote monitoring, intelligent early warning, and cloud management can be achieved, making the operation of the fire protection system more intelligent and information-based. This function provides managers with higher visualization management tools, improving operational efficiency and enabling rapid decision-making and response in the early stages of a fire, significantly enhancing emergency response capabilities. In terms of performance, the rated flow of high-performance electric fire pumps typically covers a range from 50 GPM to over 3000 GPM, and the head can reach 100 meters or even higher, meeting the fire protection needs of buildings of different sizes. Its operating noise is kept at a low level, making it suitable for hospitals, shopping malls, office buildings, and other places with strict environmental noise requirements. The pump body adopts a corrosion-resistant design, adaptable to various water quality conditions, such as tap water, reservoir water, or neutral industrial water, ensuring stable operation in different environments. Its pressure resistance and protection level also meet industrial-grade standards, allowing for long-term stable operation in high-temperature and high-humidity environments, unfazed by harsh fire scene conditions. From an engineering application perspective, high-performance electric fire pumps are widely used in high-rise buildings, subways, chemical plants, power plants, warehousing and logistics centers, and other fields. Their excellent performance and reliability have made them the designated fire-fighting equipment for many projects. In actual operation, electric fire pumps are often used in conjunction with diesel fire pumps and pressure-stabilizing pumps to form a complete fire water supply system, achieving all-time, all-scenario fire protection through automated linkage. Whether in the event of a sudden fire, a sudden drop in pipeline pressure, or during system maintenance, high-performance electric fire pumps maintain stable output, ensuring the safe operation of the fire protection system. In conclusion, high-performance electric fire pumps, with their powerful performance, intelligent control system, superior energy-saving characteristics, reliable mechanical structure, and comprehensive protection functions, have become an irreplaceable key piece of equipment in modern building fire protection systems. They not only provide continuous and stable water pressure support for safety protection, but also set new industry benchmarks in energy saving, intelligence, and system reliability. In the future, with the increasingly prominent trends of smart fire protection and green building, high-performance electric fire pumps will continue to play a core role in the global fire protection market, providing more efficient, safer, and smarter fire protection solutions for various types of buildings, safeguarding lives and property.