Diesel Fire Pump for Remote and Off-Grid Areas: Powerful Performance with High Head Capability

High-performance diesel fire pumps feature rapid start-up, stable water supply, and powerful output, making them suitable for industrial, commercial, and emergency fire protection systems, ensuring reliable fire protection in critical moments.

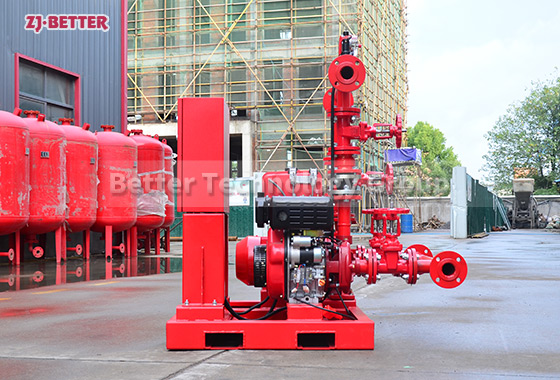

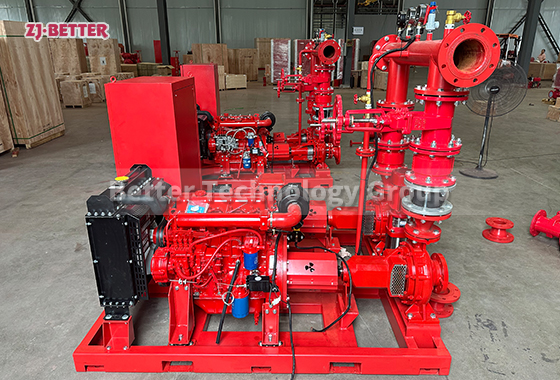

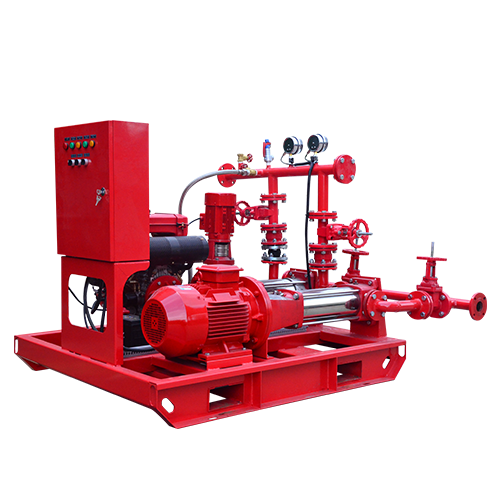

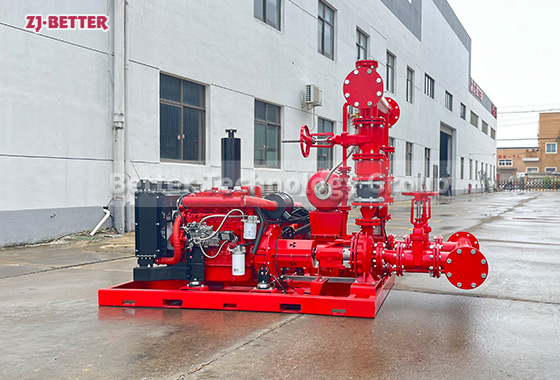

Diesel engine fire pump units are critical equipment widely used in locations with unstable power supply or extremely high fire protection requirements. Their core advantages lie in independent power, high reliability, and the ability to continuously provide stable fire water supply even in extreme conditions. These units typically consist of a high-performance diesel engine, fire pump, base, instrumentation and control system, exhaust system, and fuel supply structure. Each component is rigorously designed to ensure rapid deployment in the initial stages of a fire, buying crucial time for emergency rescue. As a vital power source for modern fire protection systems, diesel engine fire pump units are widely used in high-rise buildings, chemical plants, oil depots, commercial complexes, public facilities, and water transport terminals. Their main advantages lie in reliability, adaptability, power performance, energy efficiency, ease of maintenance, and continuous operation under multiple conditions, making them indispensable core equipment in many large-scale fire protection systems.

These units have significant advantages in power performance. The diesel engine, as the core power source, directly drives the fire pump through mechanical energy, enabling it to start quickly and operate stably even in the event of a complete power outage. Diesel engines boast high torque, strong power, and excellent fuel economy. They maintain stable performance even under high loads and prolonged continuous output, making them suitable for diverse climates, including high-temperature environments, cold regions, and areas with significant altitude differences. Furthermore, modern diesel engines employ electronic fuel injection, efficient combustion, and emission optimization technologies to ensure power output while minimizing energy waste, maintaining low fuel consumption, and ensuring emissions align with green environmental trends. In emergencies, the engine starts rapidly, typically igniting and reaching operating speed within seconds, significantly reducing the response time of fire suppression systems.

Regarding fire pump performance, these units are typically equipped with high-lift, high-flow end-suction or multi-stage centrifugal fire pumps. The pump body is constructed from high-quality corrosion-resistant materials, suitable for fire water supply scenarios with clean water or slightly impurities. The pump’s hydraulic model has been specially optimized to achieve high-efficiency operation across a wide flow range, maintaining energy efficiency and stable output, especially under the high-lift conditions most commonly used in fire suppression systems. The sealing structure utilizes mechanical seals or reinforced sealing components, capable of withstanding high-speed and high-pressure operating environments for extended periods, effectively reducing leakage risk and improving system safety. The pump shaft boasts high strength and stability, with precise matching between the coupling and the engine end, resulting in minimal operational vibration and effectively extending overall lifespan.

The intelligent control system is a crucial component of the entire unit. These diesel engine fire pump units are typically equipped with an automatic control cabinet, featuring manual start, automatic start, intelligent detection, self-protection, and fault alarm functions. The control system monitors real-time data such as diesel engine water temperature, oil pressure, speed, battery voltage, fuel level, and pump outlet pressure. In case of abnormalities, such as low oil pressure, engine overheating, or abnormally high speed, the system automatically executes corresponding protection logic to prevent equipment damage. Simultaneously, when the fire system pressure drops to a set value, the control cabinet can automatically start the diesel engine, enabling the pump unit to operate fully automatically even without human intervention. Some systems can also achieve signal linkage with the fire control center, enhancing the overall system intelligence.

In terms of structural design, diesel engine fire pump units generally utilize a high-strength base, capable of stably supporting the operating load of the engine and fire pump. The base structure undergoes vibration damping treatment, effectively reducing the vibration amplitude during equipment operation, improving operational smoothness, and minimizing impact on surrounding structures. The exhaust system features a high-temperature protection design, smoothly expelling diesel engine exhaust outdoors through a muffler and smoke duct, while reducing noise and improving the comfort of the operating environment. The fuel system is equipped with an independent fuel tank, capable of continuous fuel supply for several hours, ensuring long-term operation even in large-scale fires or prolonged emergency water supply. Some configurations can also be equipped with an external large-capacity fuel tank for even longer independent fire-fighting water supply capacity.

Regarding maintenance, this type of fire-fighting unit is characterized by its simple structure, long maintenance cycle, and ease of repair. The diesel engine adopts a standard modular structure for its lubrication, cooling, and intake/exhaust systems. Users can ensure long-term stable operation by regularly changing easily worn parts such as engine oil, filters, and coolant according to daily management requirements. Maintenance of the fire pump is also relatively simple; regular checks of seals, bearings, and coupling alignment are sufficient. All components have good accessibility, making maintenance quick and convenient, reducing downtime, and improving overall system availability.

In terms of safety, the unit employs comprehensive safety protection measures, including low oil pressure protection, over-temperature protection, over-speed protection, water pump shortage protection, emergency stop switch, and a multi-point alarm system, ensuring stable and reliable operation even under extreme conditions. The electrical system is also reinforced and protected, with wiring harnesses designed to be high-temperature resistant, waterproof, and oil-proof, ensuring stable transmission of control commands even in complex operating conditions.

From an applicability perspective, diesel engine fire pump units demonstrate irreplaceable advantages in environments requiring high reliability, independence, and adaptability. Whether in urban fire protection systems, industrial fire protection facilities, or independent areas far from the municipal power grid, they can serve as the core fire-fighting power source, ensuring a continuous and stable fire water supply. Especially in high-risk areas such as large industrial enterprises, petrochemical plants, and logistics warehousing bases, diesel engine fire pump units are widely used due to their excellent durability and independence from external power sources.

Overall, diesel engine fire pump units demonstrate comprehensive and outstanding performance in terms of power output, structural reliability, system intelligence, safety performance, operational continuity, and applicability, making them a key piece of equipment in modern fire protection systems for ensuring stable water supply and emergency response capabilities. Its exceptional adaptability, durability, and high reliability make it suitable not only for routine fire preparedness but also for critical moments, serving as a vital force in protecting people and property.