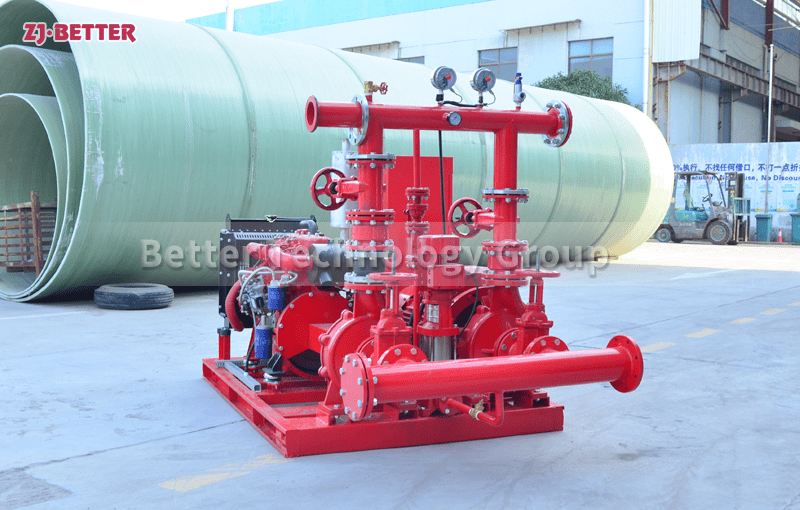

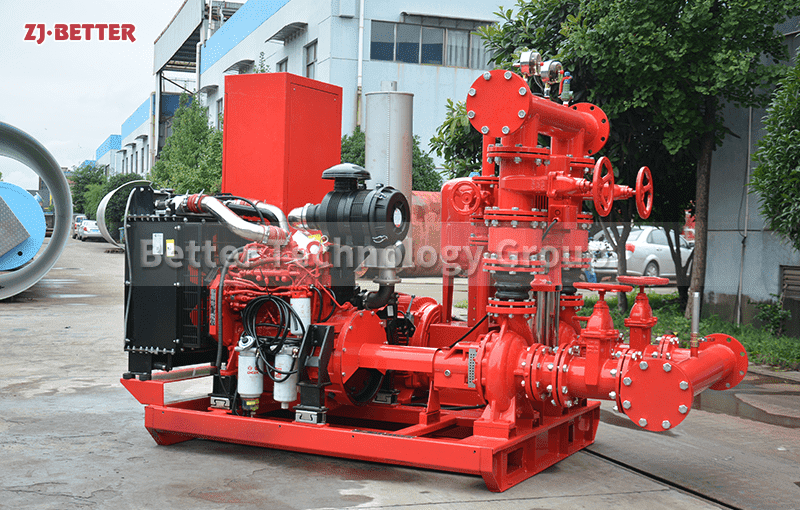

Heavy-Duty Fire Pump: Reliable Water Supply System for Petrochemical Plants and Warehouses

Heavy-duty fire pumps are high-performance firefighting equipment featuring high lift, high flow, and continuous water supply. They are suitable for large-scale firefighting systems in petrochemical, power, and high-rise buildings. Featuring a pressure-resistant, corrosion-resistant structure and intelligent control system, they offer stable operation and easy maintenance. They operate reliably even during power outages and in harsh environments, providing efficient protection for fire safety.

As core equipment in modern industrial and large-scale infrastructure fire protection systems, heavy-duty fire pumps play a vital role in various high-risk locations with their superior performance, exceptional reliability, and exceptionally long service life. They are widely used in locations requiring a stable, high-pressure water supply, such as petrochemical plants, power facilities, warehouses and logistics centers, ports and terminals, underground garages, large commercial complexes, and high-rise buildings. They ensure rapid, continuous, and sufficient firefighting water supply at critical moments, minimizing fire damage and protecting personnel and property. Heavy-duty fire pumps are typically powered by diesel engines or electric motors. Their efficient transmission system and optimized hydraulic structure achieve high head and high flow output, meeting the requirements of various pressure levels and water delivery distances. Their sophisticated structural design utilizes a high-strength cast iron or ductile iron pump body with precision milled and corrosion-resistant internal flow passages. These pumps withstand high-pressure operating conditions and the long-term impact of complex operating conditions, significantly enhancing their reliability and service life. Dynamic balancing of the pump body and impeller ensures low vibration and noise levels even at high speeds, ensuring smooth and reliable system operation. These fire pumps are also equipped with high-performance mechanical seals to prevent leakage and maintain stable pressure within the pump chamber, effectively avoiding hydraulic loss or equipment damage caused by seal failure. One of the greatest technical advantages of heavy-duty fire pumps is their exceptional high-pressure output capability and continuous water supply. Whether in the vertical water supply systems of high-rise buildings or the remote firefighting networks of petrochemical storage tank areas, they maintain constant high-pressure output, ensuring rapid response and sufficient firefighting intensity from the initial stages of a fire by fire sprinkler systems and fire hydrant networks. Especially in the event of power outages, equipment failures, or harsh environments, diesel-powered heavy-duty fire pumps can start and operate independently, independent of external power sources, providing a solid backup power source for firefighting systems. This independent operation is particularly important in emergency rescue and disaster response, ensuring that the firefighting system will not be disabled by power outages in any emergency. To meet diverse project requirements, heavy-duty fire pumps can be flexibly customized to meet site requirements, including single-stage, two-stage, and multi-stage centrifugal configurations, as well as horizontal, vertical, or a combination of horizontal and vertical installation options. The multi-stage centrifugal structure achieves higher head while maintaining high flow rates, making it suitable for applications requiring high pressure, such as power plant cooling systems or explosion-proof water supply systems in petrochemical production areas. The horizontal design facilitates maintenance and overhaul, while the vertical structure performs better in space-constrained or underground pump rooms. Its modular mounting base facilitates transportation and installation of the entire unit, expediting on-site assembly and significantly shortening the construction cycle, improving installation efficiency. The control system for these heavy-duty fire pumps is also highly intelligent and secure. Utilizing advanced electronic control modules or automatic control cabinets, the system implements functions such as one-touch start, pressure monitoring, fault alarms, automatic switching, and remote monitoring. The system can be linked to a fire monitoring center to automatically activate the pumps upon receiving a fire alarm signal or a drop in system pressure, ensuring immediate water supply. The control system also features both manual and automatic modes, allowing for flexible switching based on site needs to ensure reliable operation in all conditions. The pump unit is equipped with multiple safety protection mechanisms, including low oil pressure alarm, cooling system overheat protection, high water outlet pressure protection, and electrical short-circuit protection, ensuring stable operation under extreme conditions and preventing damage from overload or misoperation. In terms of performance parameters, the heavy-duty fire pump features high flow rate, high head, and high efficiency. Its flow rate ranges from tens to thousands of cubic meters per hour, and its head can reach hundreds of meters or even higher depending on design requirements, making it widely applicable to fire protection systems of varying sizes and requirements. The pump’s efficiency has been rigorously optimized, achieving hydraulic efficiency exceeding 80%, significantly reducing energy consumption and improving overall operating economy. The accompanying diesel engine or electric motor utilizes a high-performance power unit, offering fast start-up, strong torque, and high fuel efficiency, ensuring stable output even under high loads. To withstand the challenging environments of petrochemical and power plants, all key components of the heavy-duty fire pump are treated with explosion-proof, corrosion-resistant, shock-resistant, and high-temperature resistant treatments. This ensures long-term stable operation in extreme conditions such as high humidity, high salinity, and high temperatures, ensuring excellent performance in any environment. The cooling system utilizes forced air or water cooling to prevent the engine from overheating during extended continuous operation, significantly enhancing equipment reliability and safety. Heavy-duty fire pumps not only prioritize performance but also incorporate ease of maintenance into their design. All major components feature a modular design for easy assembly and disassembly, minimizing routine maintenance time and reducing operating costs. The pump shaft, impeller, and mechanical seal are standardized parts, allowing users to quickly purchase and replace them as needed, ensuring continuous and efficient system operation. Furthermore, to ensure long-term reliability, each fire pump undergoes rigorous performance testing before shipment, including tests for flow rate, head, efficiency, vibration, noise, sealing, and pressure resistance, ensuring all indicators meet international standards. The equipment can also be flexibly integrated with sprinkler systems, fire hydrant systems, foam fire extinguishing systems, and emergency water supply systems, enabling multi-system integration and building a complete fire water supply network. In modern firefighting projects, heavy-duty fire pumps are more than just a piece of equipment; they serve as the power center of the entire firefighting system. With their powerful performance, intelligent control, and exceptional durability, they provide stable and reliable fire safety for various industries. Whether in routine system testing or emergency response to sudden fires, heavy-duty fire pumps can be put into operation in the shortest possible time, buying firefighters valuable rescue time. Their combined high reliability, high performance, and high adaptability make them an indispensable core device in modern industrial safety systems. As global safety standards and fire protection requirements continue to improve, the application prospects of heavy-duty fire pumps will become increasingly broad. Not only will they continue to play a role in traditional industrial fields, they will also demonstrate their powerful technical advantages in new energy bases, energy storage power stations, port logistics, and large-scale infrastructure projects. With their superior performance, intelligent system control, durable structural design, and excellent energy efficiency, heavy-duty fire pumps are undoubtedly the ideal choice for building high-standard fire protection systems, building an indestructible line of defense for the safety of human life and property.