Standardized Design for Rapid Deployment: Engineering Value of Horizontal Electric Fire Pumps

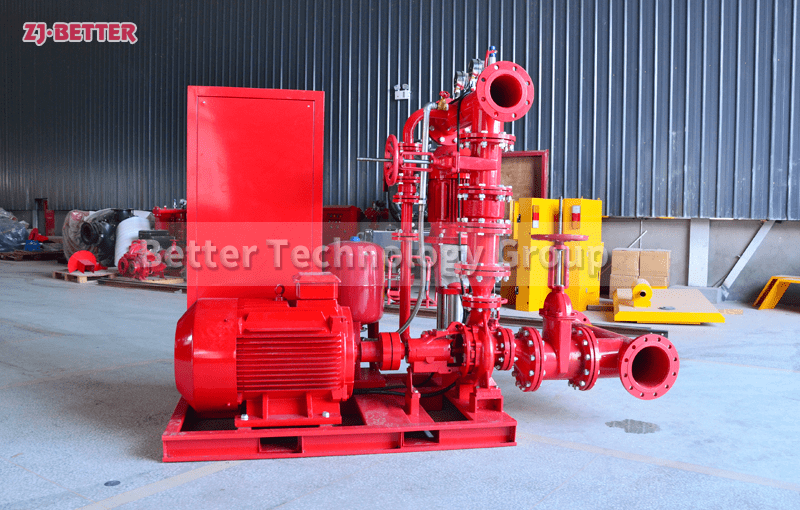

The horizontal electric fire pump features a standardized structure, easy installation, and high reliability, making it a critical solution for rapid deployment and efficient operation in modern building fire protection systems.

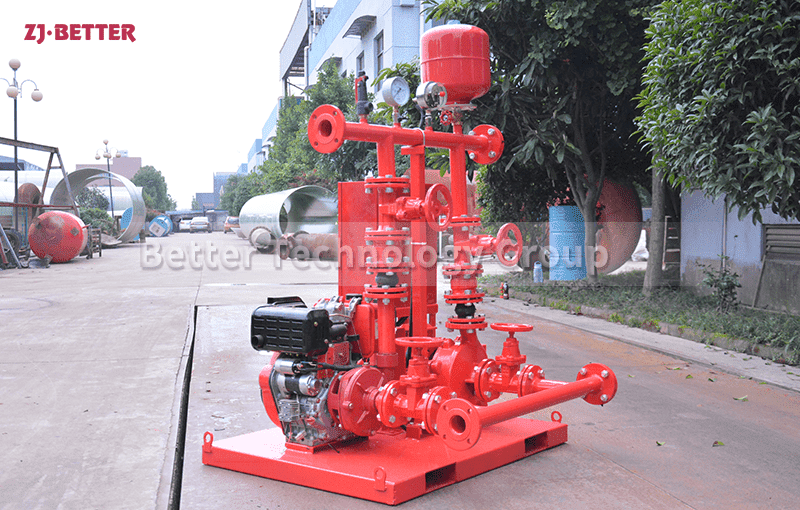

In today’s building industry and urban public safety systems, the ability to rapidly deploy and efficiently operate fire pumps has become a key indicator of emergency response capability. The horizontal electric fire pump, with its high degree of standardization, strong adaptability, and compact structure, has become a vital piece of equipment widely adopted in residential complexes, high-rise buildings, industrial plants, logistics centers, and commercial facilities.

The standout feature of the horizontal electric fire pump lies in its standardized design. The pump unit is constructed using modular components with unified installation dimensions and standardized connection interfaces, significantly streamlining the processes of design selection, on-site installation, and later maintenance. This design advantage not only improves installation efficiency but also ensures high compatibility and integration in large-scale projects or parallel pump systems. During the fire protection design phase, this pump type can be seamlessly integrated into CAD or BIM platforms, allowing accurate alignment from equipment selection to piping layout.

From a technical standpoint, horizontal electric fire pumps typically adopt a single-stage or multi-stage centrifugal design. The electric motor and pump body are precisely aligned via a flexible coupling, ensuring smooth operation with low noise and minimal vibration. The pump casing is commonly made from high-strength cast iron or stainless steel, capable of withstanding high pressure and resisting corrosion, making it suitable for demanding firefighting water transfer conditions. Additionally, the electric motor complies with national energy efficiency standards, offering fast startup and robust overload protection to guarantee reliable water supply during emergencies.

In terms of maintenance, the horizontal layout of the pump provides ample working space for easy disassembly and quick replacement of wearing parts, significantly reducing downtime. For projects with high-frequency usage or stringent reliability requirements, this maintainability is a major advantage. Some models are also equipped with intelligent control panels that support remote monitoring, allowing real-time status tracking, predictive maintenance, and fault preemption.

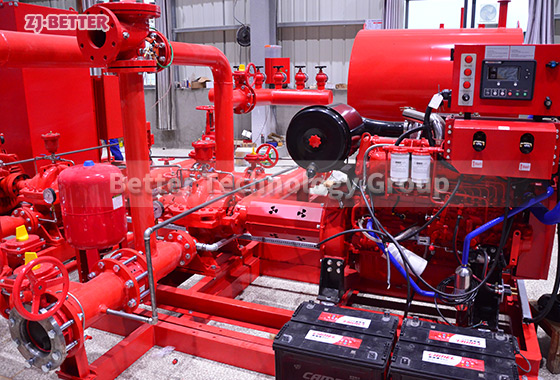

Horizontal electric fire pumps are suitable for a wide range of fire suppression systems, including pressure stabilization, sprinkler, and hydrant networks. They can automatically start and stop based on preset pressure levels, maintaining system pressure within safe limits while balancing energy efficiency and performance. These pumps comply with national standards such as GB6245 Performance Requirements and Test Methods for Fire Pumps, and can also be UL and FM certified to meet international market requirements.

As urbanization accelerates and building structures become more complex, fire protection systems are becoming more sophisticated, demanding higher reliability and sustainability from pumping equipment. With its universal engineering applicability, broad adaptability, and easy maintenance, the horizontal electric fire pump is becoming a core component in the next generation of intelligent fire protection systems. It is more than just a product—it is an engineering solution aligned with the future of building safety.

.jpg)