Innovative Design, Premium DJ Fire Pump Systems

1.Flow:30-9000 GPM

2.Head: 3-20 Bar 40-300 psi

3.Power:Diesel & Electric Pump:1.5-710kw Jockey Pump:0.55-160kw

4.Speed:740-2900 r/min

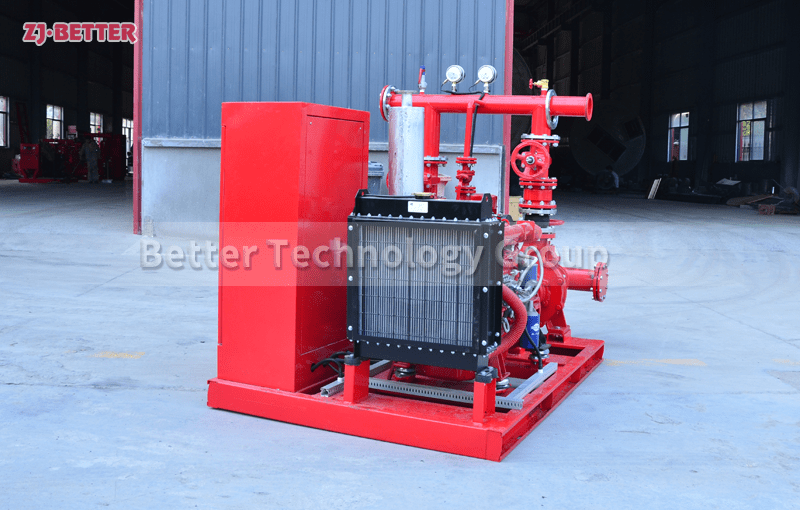

The DJ Fire Pump Set is a combination system consisting of a diesel engine pump and a jockey pump, designed for fire safety in the construction and industrial sectors.

Types of pumps used for fire service include: End Suction Pump, Split Case Pump, Vertical Inline Pump and Vertical Turbine Pump.

1.Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank, fan,control box.

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump.

3. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, over current protection.

By choosing the DJ (Diesel engine pump + Jockey pump) Fire Pump Set, you opt for a reliable, efficient, and secure solution to protect your property and ensure the safety of occupants. Whether for commercial buildings, industrial facilities, or residential areas, it is an indispensable fire safety equipment that offers robust support and protection to your fire protection system.