New Standard in Fire Protection: The Comprehensive Advantages of Dual-Power Fire Pumps

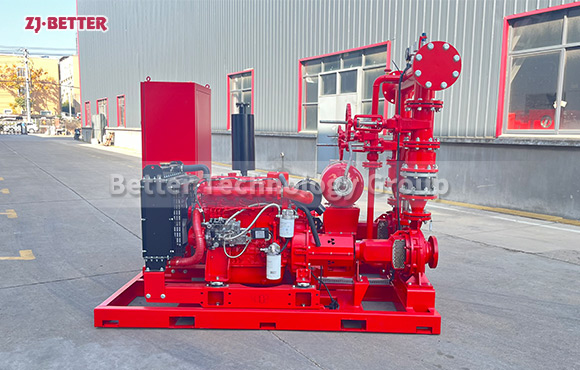

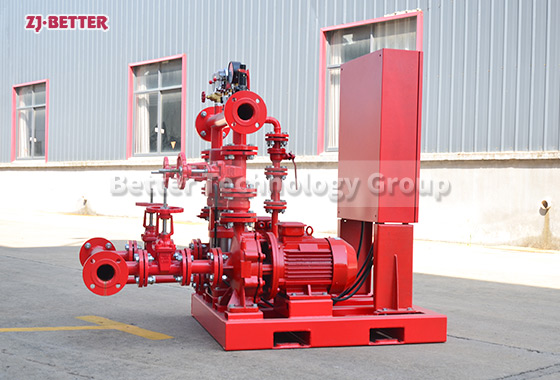

The dual-power fire pump unit, combining both electric motor and diesel engine drive, is a core component of modern fire protection systems. Its greatest advantage lies in its ability to operate reliably whether or not the main power supply is available, ensuring uninterrupted water delivery during emergencies.

This pump unit features an integrated design with electric and diesel pumps, an automatic control cabinet, a shared base frame, and a unified piping system. It allows for fast installation and quick commissioning, significantly enhancing onsite construction efficiency. The intelligent control system provides full automatic switching—once a power outage is detected, the diesel engine starts immediately to ensure timely fire suppression response.

Built from high-performance materials, the dual-power unit offers strong corrosion resistance and operational stability, making it ideal for use in industrial facilities, high-rise buildings, and large commercial complexes.

As a high-tech enterprise specializing in the research, production, and service of fire pump systems, we are dedicated to delivering efficient, safe, and intelligent fire protection solutions tailored to the evolving needs of global customers. Our product portfolio includes electric fire pump sets, diesel engine-driven fire pumps, jockey pumps, control panels, mobile pump units, dual-power fire pump systems, and various customized integrated pump packages. These systems are widely applied in high-rise buildings, underground infrastructure, petrochemical plants, industrial facilities, water projects, and municipal engineering.

We operate a modern manufacturing base equipped with automated machinery and advanced performance testing platforms, ensuring strict quality control throughout the entire production process—from raw material selection to final assembly and delivery. Our products comply with major international standards such as GB6245 and NFPA20, and we offer customization services to meet unique specifications from different countries and industries.

Our R&D team is composed of experienced engineers with strong backgrounds in mechanical engineering, fluid dynamics, and smart control systems. This enables us to continuously innovate, upgrade, and adapt our product offerings. We also emphasize intellectual property protection and have secured several national and international patents.

Our comprehensive service system includes technical consulting, solution design, on-site guidance, and after-sales maintenance. With fast-response support and an established global logistics network, we ensure timely delivery and efficient operation for every client project.

Currently, our products are exported to over 50 countries across Southeast Asia, the Middle East, Africa, Europe, and the Americas. We have built long-term partnerships with international engineering contractors and government fire protection projects. Looking ahead, we remain committed to the principle of “quality ensures safety, service earns trust,” and we strive to provide world-class fire protection solutions to clients around the globe.