Smart Fire Protection Upgrade: Diesel Pump System with Remote Monitoring Capabilities

Explore the advanced diesel engine fire pump system with remote monitoring capabilities, offering reliable performance, automatic control, and real-time data tracking for high-risk and power-outage-prone environments.

Diesel-powered fire pump systems equipped with remote monitoring capabilities are a crucial component of emergency fire water systems in modern buildings, industrial parks, and high-risk locations. These systems, based on traditional diesel engine pumps, have undergone intelligent upgrades, seamlessly integrating automatic control with remote monitoring. This not only significantly improves the system’s response efficiency in emergency situations but also provides managers with comprehensive operational status visibility at all times. These systems typically utilize a high-performance diesel engine as their primary power source, capable of operating independently of the power grid. This allows for continuous and stable water supply in extreme situations such as power outages or disasters, ensuring rapid and sufficient water delivery in the early stages of a fire. The power system and pump components often utilize various configurations, including horizontal end-suction, double-suction, or multi-stage pumps, with head and flow rates configured according to project requirements. The system’s integrated remote monitoring module connects to the backend platform via 4G, Wi-Fi, or wired communication, providing real-time transmission of key parameters such as pump startup status, operating speed, output pressure, water flow, oil level, engine temperature, and battery voltage. Managers can remotely access the monitoring interface via a computer or mobile app to monitor system status, analyze data, and identify faults.

The intelligent controller built into the control cabinet offers multiple startup methods, including manual, automatic, and remote control. It supports seamless switching between municipal power and diesel backup power. In the event of power system instability or unavailability, the diesel pump automatically switches into operation. Its program logic also supports multi-pump linkage control, scheduled inspections, self-tests, and fault self-diagnosis, enabling efficient and safe operation even in unattended conditions. Furthermore, the system’s alarm system covers dozens of warnings, including low oil pressure, high water temperature, low oil level, battery undervoltage, cooling fan abnormalities, and pump overload. It alerts on-site personnel through audible and visual alarms and remotely notifies relevant management personnel via the platform, facilitating timely action and mitigating potential hazards.

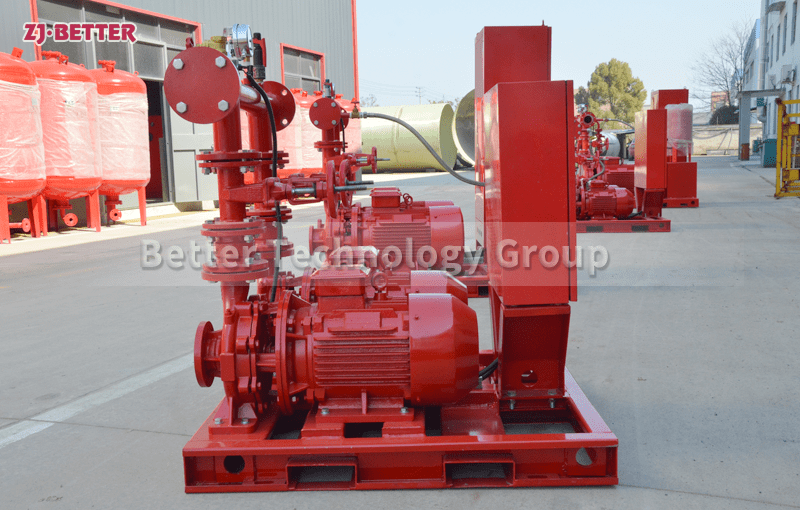

The diesel fire pump system’s piping system utilizes a modular design, constructed from high-strength carbon steel or stainless steel. Components such as automatic pressure relief valves, check valves, manual ball valves, and pressure gauges ensure enhanced stability and safety during high-pressure operation. The mounting base is welded from high-strength carbon steel, providing a stable structure and excellent seismic resistance, making it easy to hoist and transport. In terms of sealing performance, the pump shaft seal utilizes a mechanical seal design, effectively preventing leakage and extending service life. All key components undergo rigorous quality inspection to ensure the overall system operates continuously and stably for extended periods even under high loads.

Notably, the system’s control system can be linked with the automatic fire alarm system. When a fire alarm signal is triggered, the controller automatically determines whether to activate the pump set, thereby shortening response time and improving firefighting efficiency. The system also supports data history storage, allowing historical operating parameters, fault information, and operation records to be exported as reports, enabling managers to analyze equipment operating trends and develop more effective maintenance plans. Diesel fire pump sets are typically equipped with dual automatic battery charging devices to maintain a reliable supply of starting power, ensuring a successful first-time start even in extremely cold, humid, and other harsh environments. These pumps are suitable for critical locations requiring extremely high system reliability, such as the petrochemical industry, power plants, airports, docks, hospitals, and tunnels.

From a maintenance perspective, the system is designed with user-friendly interfaces in mind, featuring a touchscreen or keypad display for simple and intuitive operation. The strategic layout of key components facilitates daily inspection and maintenance. The device supports fault self-diagnosis. If it detects low battery voltage, abnormal fuel tank level, or engine speed deviation from the set range, it will immediately generate an alarm and display the specific fault point, helping maintenance personnel quickly locate the problem. Multiple sensors also monitor physical data such as ambient temperature and humidity, and unit vibration in real time. Combined with intelligent control algorithms, these sensors determine whether protective measures are needed, effectively reducing the risk of failures caused by overload, dry running, overheating, and other factors.

In addition, the device can be customized with paint color, engine brand, pump type, and functional modules based on project requirements. Some high-end configurations also support GPS positioning and movement tracking, facilitating statistics and tracking in multi-project management. The diesel pump system is highly adaptable to operating environments, eliminating the need for municipal power and complex electrical systems. It can be easily deployed and operated even in remote mountainous areas or on construction sites, even in challenging conditions. For areas with unstable water supply and frequent power outages, this type of self-powered fire pump system undoubtedly offers a higher level of safety. Overall, this remotely monitored diesel fire pump system is a modern firefighting device that combines efficiency, intelligence, and reliability, representing the current trend in high-end firefighting products. It not only improves emergency response efficiency, but also greatly reduces the burden of operation and maintenance, providing a more robust fire barrier for various buildings and critical infrastructure. It is a cost-effective solution that is truly worth investing in.