How to Upgrade Your Existing Fire Pump System

Discover when and how to upgrade your fire pump system to meet modern safety standards, improve performance, and ensure long-term reliability.

As building codes evolve and fire protection demands increase, your fire pump system may require an upgrade to remain compliant and reliable. Whether your current system is outdated, underperforming, or non-compliant with NFPA 20, upgrading can significantly improve safety and efficiency.

In this article, we’ll explain the reasons for upgrading, what to evaluate, and the key steps for a successful fire pump system upgrade.

1. Why Upgrade a Fire Pump System?

There are several common triggers for a fire pump system upgrade:

-

Compliance with updated NFPA 20 or local fire codes

-

Increased building size or occupancy

-

Aging or unreliable pump equipment

-

Low performance during annual flow testing

-

Obsolete or non-serviceable controllers and components

-

Insurance or AHJ (Authority Having Jurisdiction) requirements

Upgrades can help reduce risk, lower maintenance costs, and avoid system failure during an emergency.

2. Evaluate Existing System Components

Before upgrading, conduct a full evaluation of your current system:

-

Fire pump type and capacity (electric or diesel, flow/pressure specs)

-

Controller condition (age, type, compatibility)

-

Piping and valves (corrosion, layout, flow issues)

-

Power supply and backup systems

-

Pump room layout (compliance with NFPA 20 space and access requirements)

If any element fails to meet code or performance standards, it should be considered for replacement or redesign.

3. Determine New System Requirements

Base your upgrade on current building data and updated fire protection needs:

-

Total sprinkler or standpipe system demand (GPM and PSI)

-

Peak occupancy or fire risk levels

-

Whether the building needs to be divided into zones

-

Compliance with local seismic, environmental, or noise control regulations

Work with a licensed fire protection engineer or system designer to ensure the new system matches your needs.

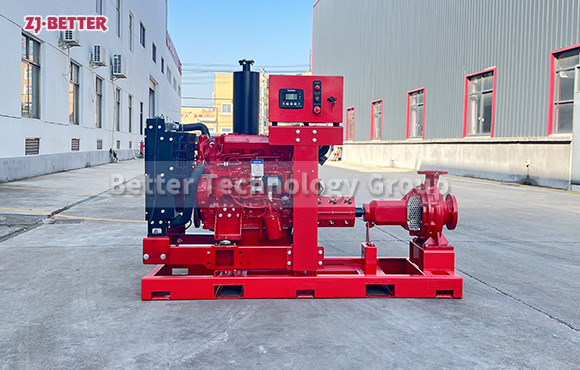

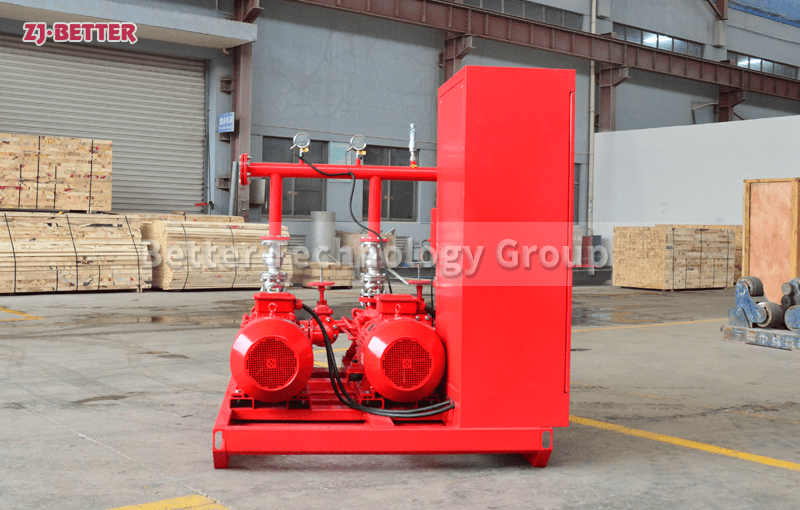

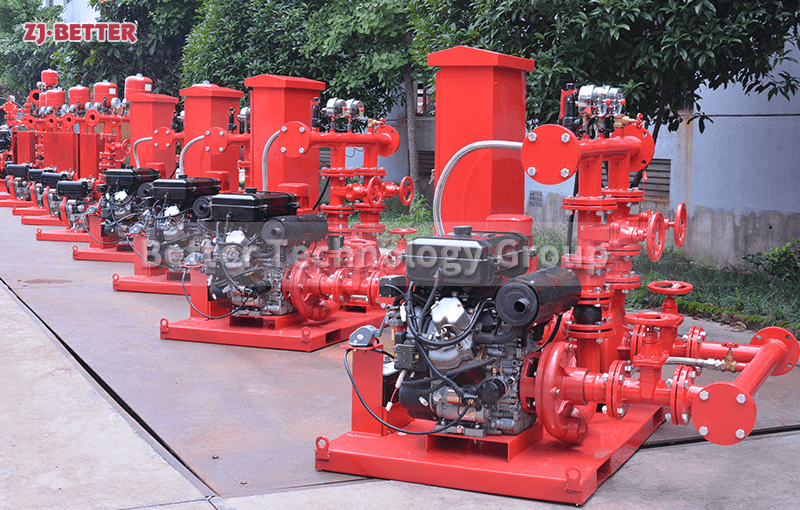

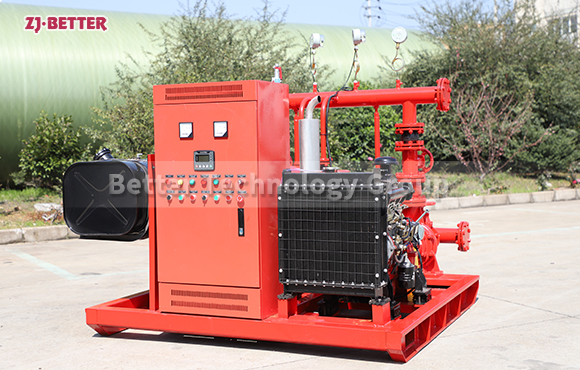

4. Select the Right Fire Pump Equipment

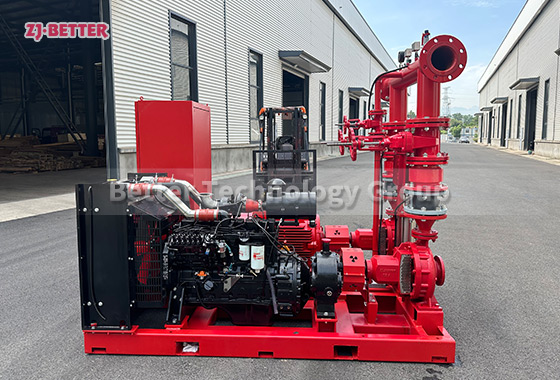

When upgrading, consider modern pump options that offer:

-

Higher efficiency and reliability

-

UL/FM certification and NFPA 20 compliance

-

Electric or diesel models suited to your infrastructure

-

Pressure relief valves, jockey pumps, and test headers

-

Smart controllers with remote monitoring capabilities

Also consider pre-engineered fire pump skid packages that simplify installation.

5. Upgrade Fire Pump Controllers

Controllers are the heart of the system. Modern units offer:

-

Touchscreen interfaces and digital status displays

-

Event logging and communication with building systems

-

Multiple start methods (manual, automatic, remote)

-

Automatic transfer switches for diesel/electric backup systems

Upgrading an old controller enhances safety and makes maintenance easier.

6. Plan for Minimal Downtime During Installation

Coordinate with fire authorities to minimize risk during the transition. Steps include:

-

Notifying your insurance provider and AHJ

-

Scheduling upgrades during low-risk building occupancy hours

-

Using temporary fire protection measures (e.g., fire watch, backup water supply)

-

Conducting a full system test and inspection after installation

Ensure a smooth switch-over without compromising building safety.

7. Conduct Commissioning and Acceptance Testing

Once the upgraded system is installed:

-

Perform a flow test to validate pressure and flow rate

-

Test all alarms, controllers, and automatic start functions

-

Ensure diesel systems are fueled, vented, and heated (if needed)

-

Submit final reports and certifications to AHJ

Proper commissioning ensures your upgraded system works flawlessly from day one.

Conclusion

Upgrading your fire pump system is a strategic investment in safety and compliance. Whether replacing worn-out equipment, increasing system capacity, or bringing your system up to code, a thoughtful upgrade ensures your fire protection infrastructure is ready for the future.

Be proactive—don’t wait for a fire or inspection failure to make improvements.