Heavy-Duty Dual-Drive Fire Pump Solutions for Large Buildings and Critical Sites

The dual-power fire pump group combines electric and diesel drives to ensure continuous water supply to large buildings under various working conditions. It is suitable for key places such as high-rise buildings, hospitals, and airports.

In modern large-scale building fire protection systems, continuous and stable water supply capacity is essential. Especially for high-density use areas such as hospitals, high-rise complexes, subway stations, large shopping malls, airports, industrial plants, storage and logistics centers, once a fire occurs, water supply interruption or slow response may lead to major safety accidents and property losses. In order to ensure that the fire protection system can still operate normally under various extreme environments, the dual-power fire pump group came into being and became a key component of the fire water supply system of large buildings. The equipment integrates two independent drive modes, electric motor and diesel engine, which can realize automatic switching between main and standby, emergency activation in case of power failure, and continuous and uninterrupted water supply. It is an important technical means to improve the overall system reliability, response speed and adaptability. The dual-power pump group is generally composed of an electric motor pump group, a diesel engine pump group, a public pipeline system, an intelligent linkage control cabinet, a pressure detection device, a valve assembly and a common base. The layout of each module is reasonable and the control logic is clear. It can operate independently or work together to meet the fire extinguishing needs of the building under different power supply conditions and working conditions. The motor pump group works under normal city power supply conditions with high efficiency, stable operation and low noise. It is the main water supply unit of the daily fire protection system; while the diesel engine pump group is used as a backup power, which can quickly take over when the power is interrupted, the power grid fluctuates or the main pump fails, ensuring that the fire water supply is not interrupted and realizing the emergency guarantee of “never falling offline”.

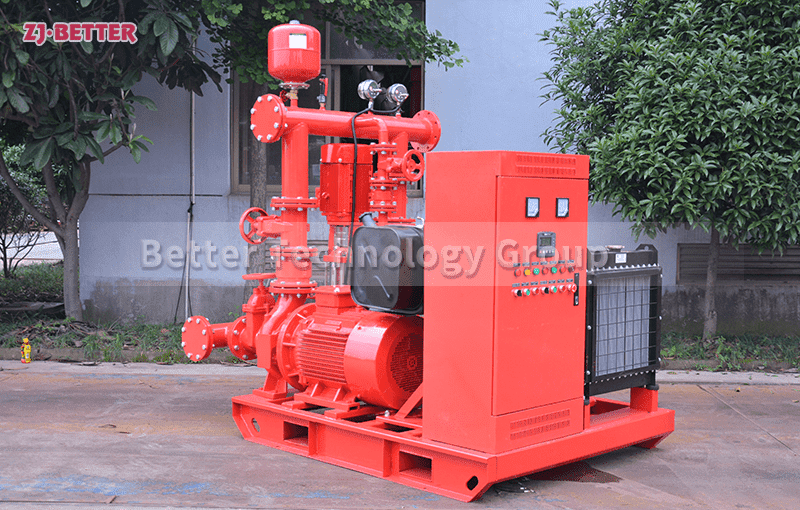

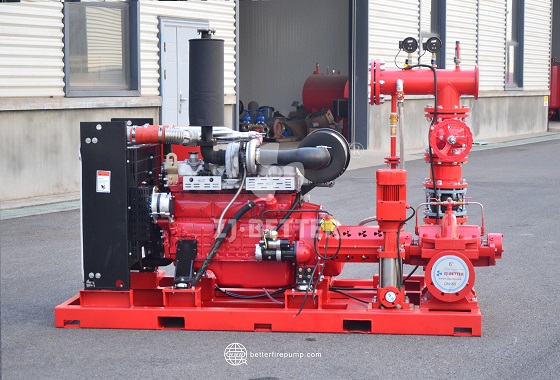

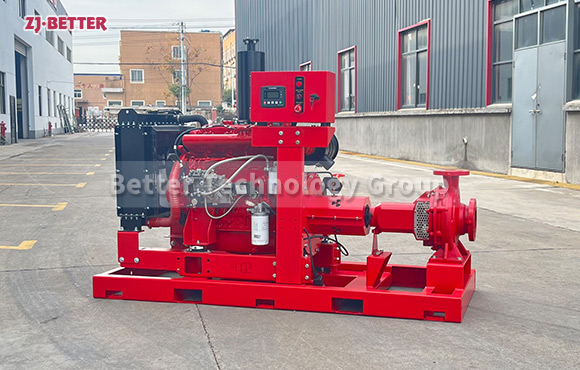

The biggest technical advantage of this equipment lies in its redundant design concept, that is, if any drive system fails, another system can immediately take over the water supply task. The motor part adopts an efficient and energy-saving motor with rapid start-up and stable power output. The matching pump body is a horizontal or vertical single-stage centrifugal pump with a wide range of flow and head, which is suitable for the fire protection pipe network requirements of different buildings. The diesel engine part uses an industrial-grade power system with large torque output and strong load resistance. It can operate continuously at high load for more than several hours and is suitable for high-intensity continuous water supply tasks. The pump group starting methods include manual, electric start and automatic linkage. The system control logic can be set according to the user to realize automatic master-slave switching under specific conditions, truly achieving “electricity when there is electricity, diesel when there is no electricity”, ensuring that the equipment automatically intervenes in emergencies and improving the system response speed. At the daily maintenance level, the built-in intelligent control system of the equipment can monitor the operating status, oil pressure, water temperature, current voltage, pump pressure, alarm information, etc. in real time, and synchronize the data to the fire monitoring center through the control panel or remote communication interface, which is convenient for managers to make early warning judgments and status management, greatly improving the intelligence of the system and the efficiency of daily maintenance.

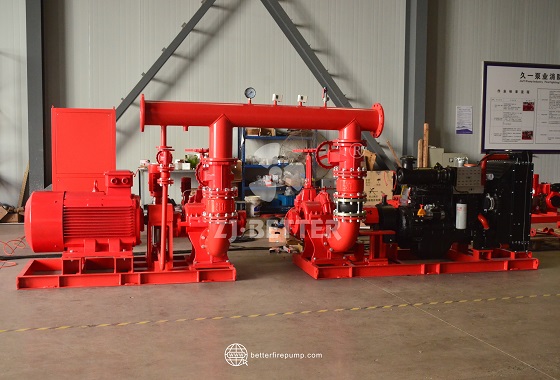

In addition, the dual-power pump group is highly modular in structure, and the whole machine design focuses on space utilization and installation convenience. All components are fixed on a high-strength steel base, which is equipped with a shock absorber and a hoisting hole to facilitate equipment transportation and quick installation. The motor end and the diesel end are arranged on the left and right sides respectively, and the pump body is located in the middle, sharing the water suction and water discharge pipeline system and the check valve and gate valve components, which not only reduces the piping cost, but also simplifies the system logic. The pipeline part is treated with corrosion-resistant spraying, and the interface is tightly sealed, which can effectively withstand pressure and prevent leakage. The control cabinet is located on one side of the equipment and adopts a metal protective box with dustproof, waterproof and explosion-proof functions. The panel layout is humanized, and the operation is simple and clear, which can be quickly completed even in low light or emergency conditions. The diesel engine is equipped with an independent fuel tank, cooling system, and exhaust silencer. The noise is well controlled when the equipment is running, and it will not cause much interference to the surrounding environment. Some models are also equipped with a heating start device and a low-temperature auxiliary system to ensure that the equipment can also start quickly and operate stably in low-temperature areas.

In practical applications, dual-power fire pump groups are widely used in places with extremely high requirements for firefighting reliability. For example, in crowded areas such as airport terminals and subway transportation hubs, once a power outage occurs, traditional electric fire pumps will be completely paralyzed, and diesel engines as independent energy systems can intervene quickly to win precious time for firefighting. In high-rise buildings, the water pressure demand is relatively large. The dual-power pump group can support multi-pump cascade configuration, adjust the head according to the floor height, and ensure that each floor can obtain sufficient water pressure. In places with complex environments and variable risks such as industrial plants and chemical parks, the dual-power design can prevent water supply failures due to circuit aging, overload or equipment maintenance, and significantly improve the overall stability of the system through the coordinated guarantee of the main and standby. Even in remote construction sites, outdoor temporary buildings or areas with unstable city power, the equipment can operate independently through the diesel power system to achieve “self-generation and self-water supply” fire emergency protection. In some smart cities and smart building systems, the dual-power pump group can also be connected to the cloud platform and the fire Internet of Things system. Through data visualization, remote start and stop, automatic inspection and other functions, it can achieve all-weather remote supervision and intelligent scheduling, improve management efficiency, and reduce manual intervention.

In terms of energy saving and operation and maintenance costs, the dual-power fire pump group adopts an electric priority and diesel standby operation strategy. During daily standby and testing, only the motor can be enabled to operate, reducing fuel consumption and carbon emissions, and saving operating costs; the diesel system is automatically tested and tested regularly to ensure that it is on standby at any time. The entire system is easy to maintain, the motor end is almost maintenance-free, the diesel engine has a clear oil and filter element replacement cycle, and the accessories are highly universal. The maintenance team can easily complete the maintenance work according to the instruction manual or remote prompts. Manufacturers usually provide detailed factory test reports, installation guide drawings, wiring diagrams, maintenance manuals and after-sales training to ensure that users can obtain professional technical support throughout the entire process of purchasing, installation, use and maintenance, and improve product experience and life cycle value.

In summary, the dual-power fire pump group is a high-reliability water supply solution for large-scale building fire protection systems. It has multiple advantages such as flexible main and standby switching, adaptability to various working conditions, scientific and reasonable structure, perfect intelligent control, stable and efficient operation, etc. It plays an irreplaceable and important role in ensuring continuous water supply to building fire protection systems, improving fire response speed, and optimizing the overall safety of the system. With the continuous upgrading of urban construction and the continuous improvement of fire safety standards, more and more construction projects and operating units have begun to include dual-power pump groups in standard configurations. As one of the core equipment to ensure the continuous and stable operation of fire protection systems, its application prospects will become more and more extensive, and it is an important fire protection equipment worthy of priority selection.

.jpg)