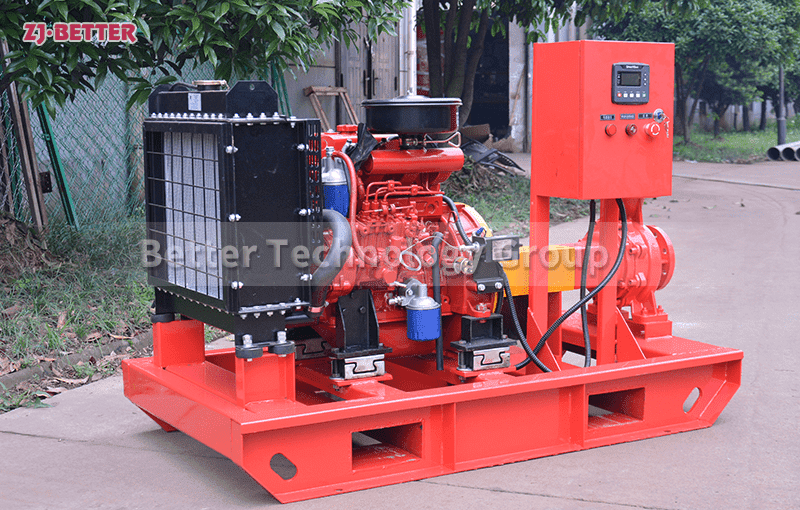

Diesel engine fire pump is safe and reliable

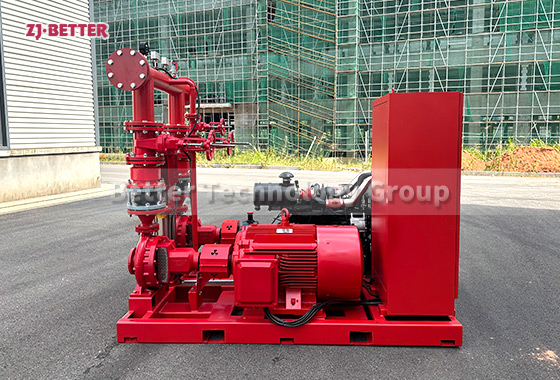

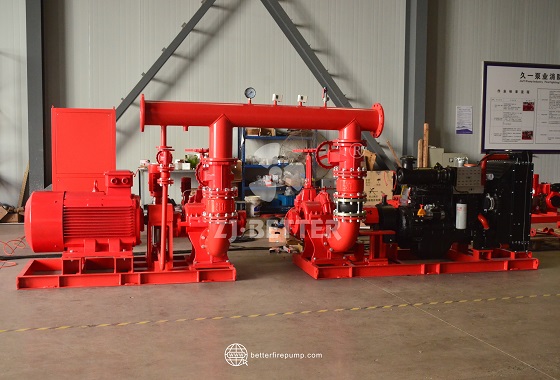

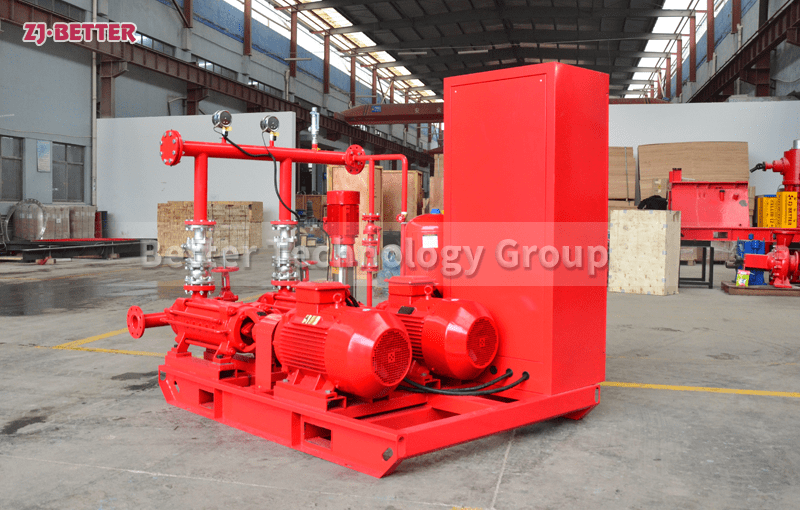

Diesel engine fire pump is simple in structure, reliable in performance, small in size, light in weight, good in corrosion resistance, low in power consumption, easy to use and maintain, suitable for urban environmental protection, construction, fire protection, chemical industry, pharmaceuticals, dyes, printing and dyeing, brewing, electricity, electroplating , papermaking, petroleum, mining, equipment cooling, tanker unloading, etc. Diesel engine fire pumps are used in warehouses, wharfs, airports, petrochemicals, power plants, liquefied gas, textiles, ships, tankers, enterprise backup and other fire-fighting water supply in various occasions, and can also be used for domestic water supply.

Diesel engine fire pump has high overall rigidity, high strength and high torque transmission efficiency. It adopts advanced technology and gantry body, sliding bearings, plate-fin cooler, top-mounted heat exchanger, spin-on oil filter and double cooling system. The performance of the diesel engine fire pump is superior, the smoke level and noise index reach the national first-class product, the fuel consumption is lower than the national standard first-class product by more than 2.1g/kW.h, the degree of automation is high, it has automatic, manual and fault self-checking functions, and the whole process monitors the working status , It can restore the function of automatic restart if the failure starts, automatic pre-lubrication and pre-heating, making the equipment start-up safer and more reliable.